Friedrichshafen (Germany), May 27, 2025. As a global plant engineering company, Zeppelin Systems is a single source for supplying integrated complete solutions for the efficient processing of raw materials. The company will attend Battery Show Europe in Stuttgart to showcase its expertise in the field of battery mass production: Namely powerful high-performance mixers, innovative mixing processes and efficient material conveying and dosing systems for the production of battery masses. Europe’s largest trade fair for the battery industry takes place June 3-5, 2025. Experts from Zeppelin Systems will greet visitors at Booth 8-A75 at the Battery Show 2025.

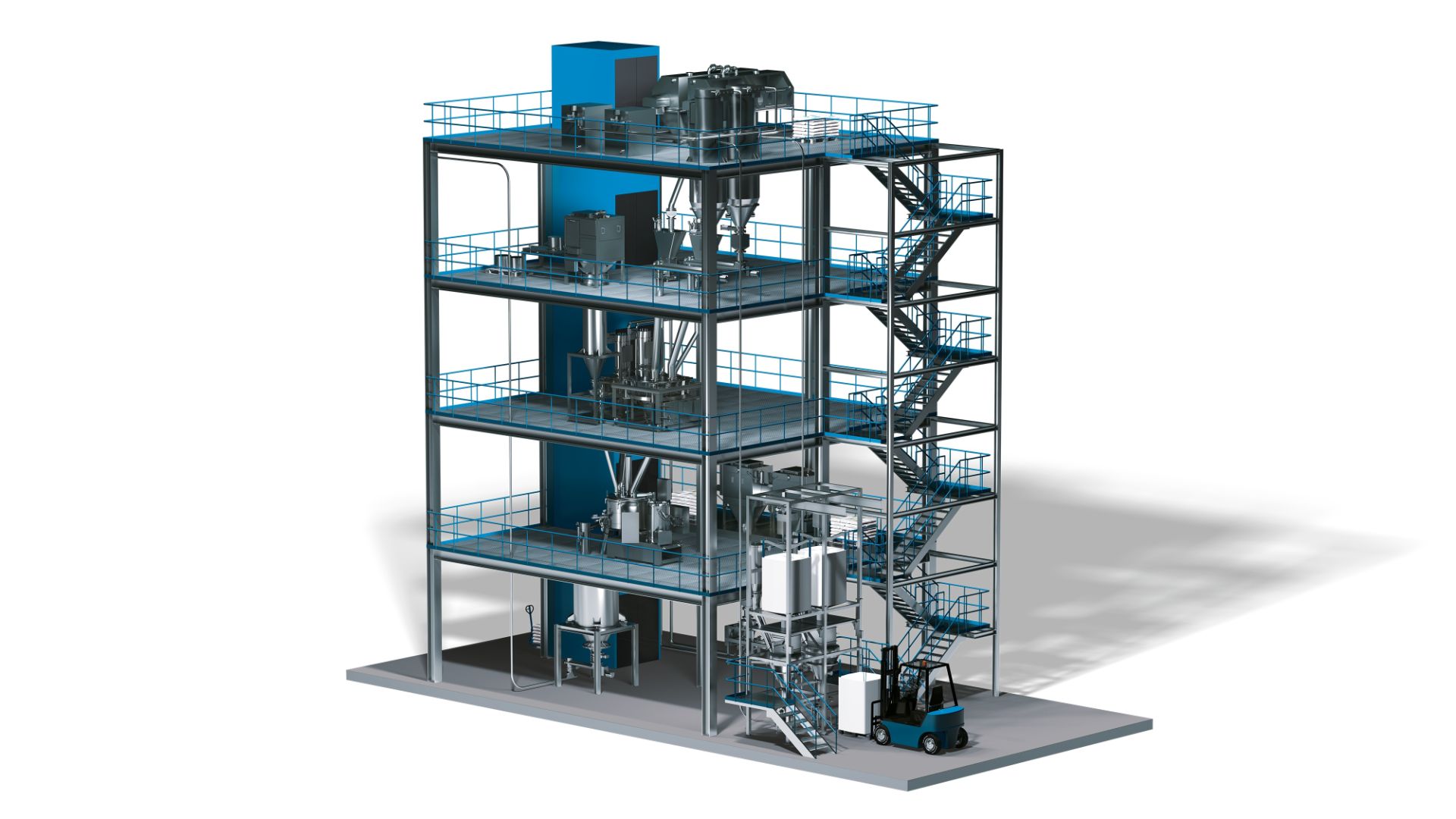

Zeppelin Systems is specialized in the conception, planning, realization and technological upgrading of industrial plants for storing, conveying, mixing, dosing, and weighing high-quality bulk materials and raw materials.

"The international battery market continues to grow in importance. Our products and solutions have already convinced many customers – and that motivates us to work on further developments and innovations to serve this important future market," explains Sascha Stiller, CEO of Zeppelin Systems GmbH. "Our expertise is valuable at various steps of battery mass production. With many years of industry experience we are well-equipped to react quickly and flexibly to our customers’ requirements."

Professional raw material handling

Raw material handling is of key importance in the production of dry-coated electrodes for batteries. As well as rapid emptying of very diverse containers, it also involves gentle pneumatic conveying that does not segregate the finished product. Sophisticated containment technology is required for the safe handling of toxic raw materials. The individual components of the final product must be dosed into the mixer with high precision and reliably discharged. The Zeppelin Systems Batch Management System ensures that batches produced are subsequently completely traceable.

Reliable and flexible material dosing for calender feeding

As well as raw materials being handled correctly, it is also essential that they are continuously and precisely dosed. The feeding and dosing unit (FDU) from Zeppelin Systems facilitates continuous and evenly distributed material feed to the calender rolls, while automatic level monitoring inside the hopper prevents the rollers from running empty. "Our newly developed stepless hopper-width adjustment enables customers to set different film widths on their calenders. The FDU can be mounted on all conventional calender types and is available for a wide range of roller widths and diameters," explains Hubert Stojanovic, Chief Sales Officer (CSO) at Zeppelin Systems GmbH. "The special geometry of the hopper, combined with ultrasonic sensors, also prevents bridging of the product and thereby ensures reliable and continuous operation. Furthermore, the dust generated is extracted directly from the hopper and chute, ensuring compliance with the applicable exposure limits," he adds.

High-intensity mixers for optimal results

The mixing of raw materials is the fundamental process step in producing battery masses. Powerful, powerful high-intensity mixers FM from Zeppelin Systems enable raw materials to be dispersed and homogenized highly efficiently. This makes them ideal for resource-friendly and safe production of battery masses in dry mixing (DBE) and semi-dry mixing processes. Specifically changing the particle structure makes it possible for both the bulk density and the energy density to be increased. Furthermore, the mixers offer customized wear protection, which ensures a long service life even with abrasive raw materials.

Zeppelin Systems test centers – tailored process optimization

Zeppelin Systems operates various test centers for testing and improving process-critical production steps. One example is the Test Center for Mixing Technology in Kassel, where processes are developed and tested at laboratory and production scale, on individually configurable mixers. Test series have already been conducted with different customers and research institutions with various AAMs (anode active materials) and CAMs (cathode active materials), such as LFP, NCA, NCM and graphite. The various products’ behavior with regard to fluidizability, time hardening, discharge behavior, product destruction, etc. are investigated at the test center in Friedrichshafen. Zeppelin Systems is currently creating a separate test setup here to facilitate testing for customers of calender dosing in respect of various AAMs and CAMs. In addition, a very wide range of product analyses are carried out in the company’s own bulk material laboratory; these include moisture measurement, particle size and distribution, bulk density determination, and shear tests.

More than 150 gigawatt hours of projects implemented to date

Zeppelin Systems is involved in numerous national and international research and development projects to further improve processes for production of battery masses. Notable examples are the EU-funded GIGABAT project and the German GUTBatt project. GUTBatt is about process development of scalable material structuring and calendered dry electrode production for lithium-ion batteries with liquid and solid electrolytes.

Zeppelin Systems’ battery mass expertise is substantially demonstrated by our worldwide customer projects, in which we have implemented systems with a total capacity exceeding 150 GWh. Customer projects have so far been completed in Germany, Sweden, the USA, India and South Korea.