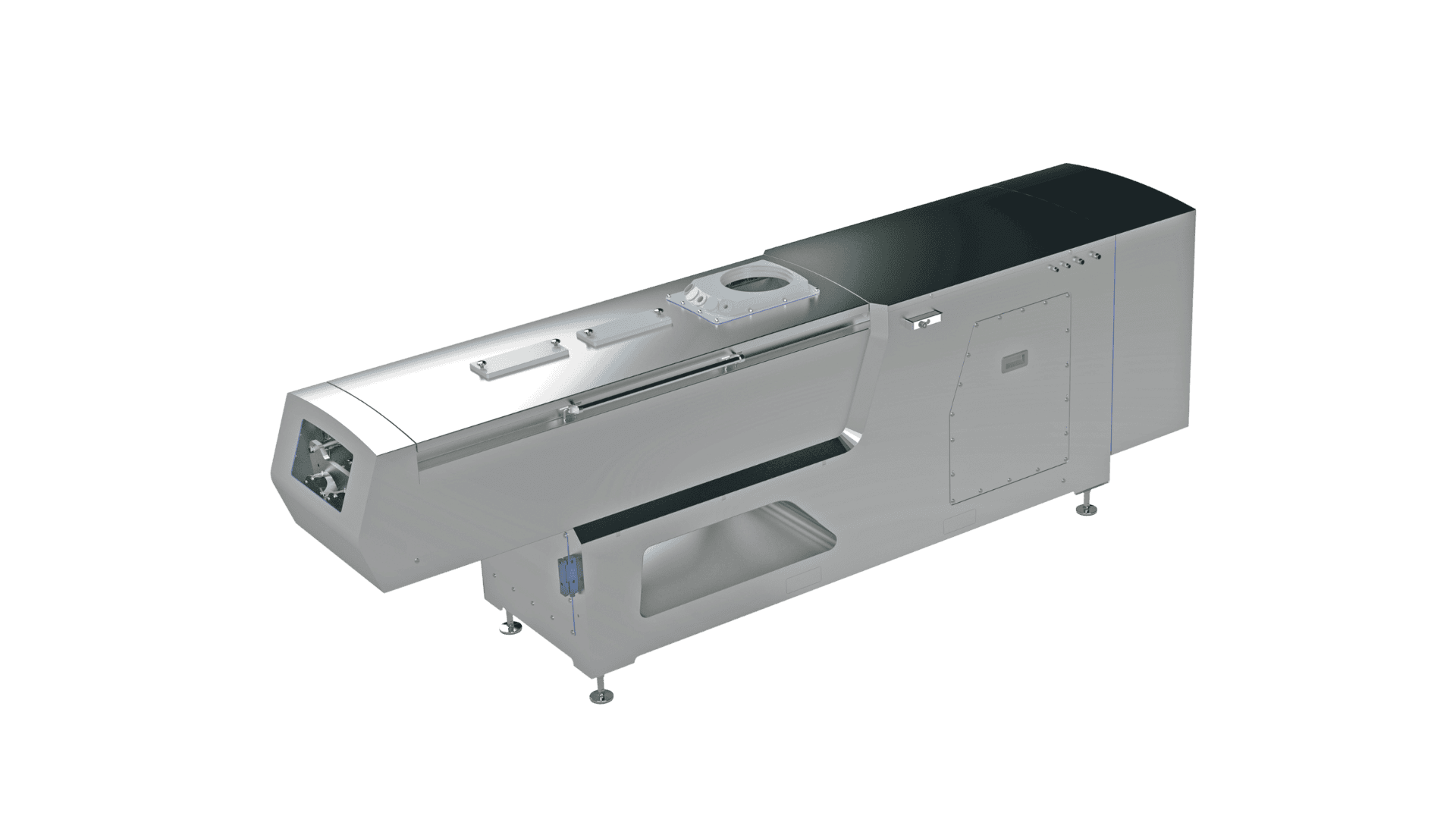

CODOS® NT

Produce high-quality doughs continuously

The Codos® NT at a glance

20,000 pretzels per hour, 2 million rolls daily, 4 tons of cookie dough per hour – the continuous mixer/kneader Codos® NT is built for large-scale production and delivers consistent dough quality around the clock. This ensures the same optimal result at any time. Whether for mono lines or flexible lines for different products, long-life or fresh baked goods – the Codos® NT offers versatile application.

Features

Design: Centered position and 90° rotation of gearbox and motor block

Drive system: Latest generation of electric, water-cooled servo motor technology for optimized control

Size: Reduced size and weight of motor and gearbox

Energy consumption: Up to 30% lower energy usage with higher yield

System integration: Control cabinet with CPU, two independent cooling circuits for the drive, trough, and control cabinet

Optional: Additional data analysis capabilities from the new drive and load cell systems

You can find more information in the product brochure:

Benefits

Special Highlights

Compact and powerful

The water-cooled servo motor of the Codos® NT delivers high torque with minimal space requirements while reducing energy costs compared to conventional three-phase motors.

Easy operation, simple maintenance

Thanks to the large maintenance openings and the easy-to-open lid, maintenance work can be carried out quickly and easily. Seals, bearings, and couplings can be replaced without dismantling the shaft – saving both time and money.

High sealing integrity

With IP66 protection, the Codos® NT is well protected against powerful water jets. When optionally mounted on load cells, it enables precise monitoring of the current fill level.

Maximum flexibility thanks to modular design

The modular design allows for individual customization: standard lids, swivel lids, or cleaning lids (WIP) can be exchanged as needed. Variable filling elements are available for liquid components.

Minimized downtime through easy cleaning

A well-designed construction enables quick and easy cleaning, minimizing downtime. Naturally, the Codos® NT meets all hygiene regulations.

Optimized trough design

The double-walled container design ensures efficient cooling and maximum performance.

Versions

- CODOS ® NT 160: Dough output ca. 3t/h

- CODOS ® NT 200: Dough output ca. 4-6 t/h

Drive unit

Double-walled through

Load cells

Our advantages for the industry

The Codos® NT offers key advantages over a batch kneader, making your production more efficient and significantly enhancing quality:

Application Areas

Industries

Dough formation takes place in the horizontally operating, continuous Codos® NT kneader. Special helical, intermeshing twin shafts introduce the energy required for kneading into the dough, allowing the gluten network in the wheat dough to develop. Stirrup-shaped kneading attachments on the twin shafts ensure gentle kneading without cutting the dough.

The product-specific energy input, as well as the dough’s residence time, can be controlled via the kneading shaft speed. Thanks to the double-walled trough design, which can be both heated and cooled, the dough consistently maintains the desired temperature. This allows the target dough temperature to be kept within a narrow tolerance range.

Need more details? Our contact person will be happy to assist youq

Tobias König

Sales Manager Food Plants & Process Machines

Related Products

Additional products from the process step

The modular Codos® kneading system

Whether it’s rolls, baguettes, or other baked goods – at Zeppelin Systems, consistently high product quality is our top priority. A key requirement for this is perfectly prepared dough. That’s exactly what our innovative and continuous Codos® system delivers. The complete system consists of the Codos® tower, the DymoMix®, and the Codos® NT kneader – providing an even more efficient solution for dough production. For outstanding results in every batch.

Go to Codos kneading system

CODOS® NT

20,000 pretzels per hour, 2 million rolls per day, 4 tons of cookie dough per hour – the continuous mixer/kneader Codos® NT is built for large-scale production and delivers consistent dough quality around the clock.

Go to Codos NTOur Customer Services for You at a Glance

Show all Customer ServicesZeppelin Systems Technical Center

Resources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH