Engineering Services

Planned Success

More value for greater success – that’s why we pull out all the stops

Our engineering departments around the globe contribute their experience and expertise to optimize planning processes. The result: an innovative concept that saves both time and costs. We call this Value Engineering. For you—whether it’s a new plant or an expansion—this means a competitive advantage in the market

Benefits

Our advantages for the industry

Expertise in plant engineering

Zeppelin Systems offers not only complete plants but also a wide range of pneumatic and hydraulic conveying systems, as well as numerous silo variants for bulk material storage (Bolt-Tec, Panel-Tec) and diverse process steps such as homogenizing, screening, degassing, cooling, and more.

Global expertise

Global solutions with local integration (international footprints) through our offices in more than twelve countries.

Decades of experience and implementation

Our expertise includes feasibility studies, cost estimates, Front End Engineering Design (FEED), process design packages (PDP), and basic design packages. Additionally, we have numerous global references for polyolefin plants. Thanks to our extensive knowledge in process engineering, sales, project management, and service, we are capable of implementing your plants quickly, safely, and cost-effectively. Of course, we also support you with after-sales service.

Engineering Services

Front-End Loading (FEL)

Optimize planning processes while saving time and costs

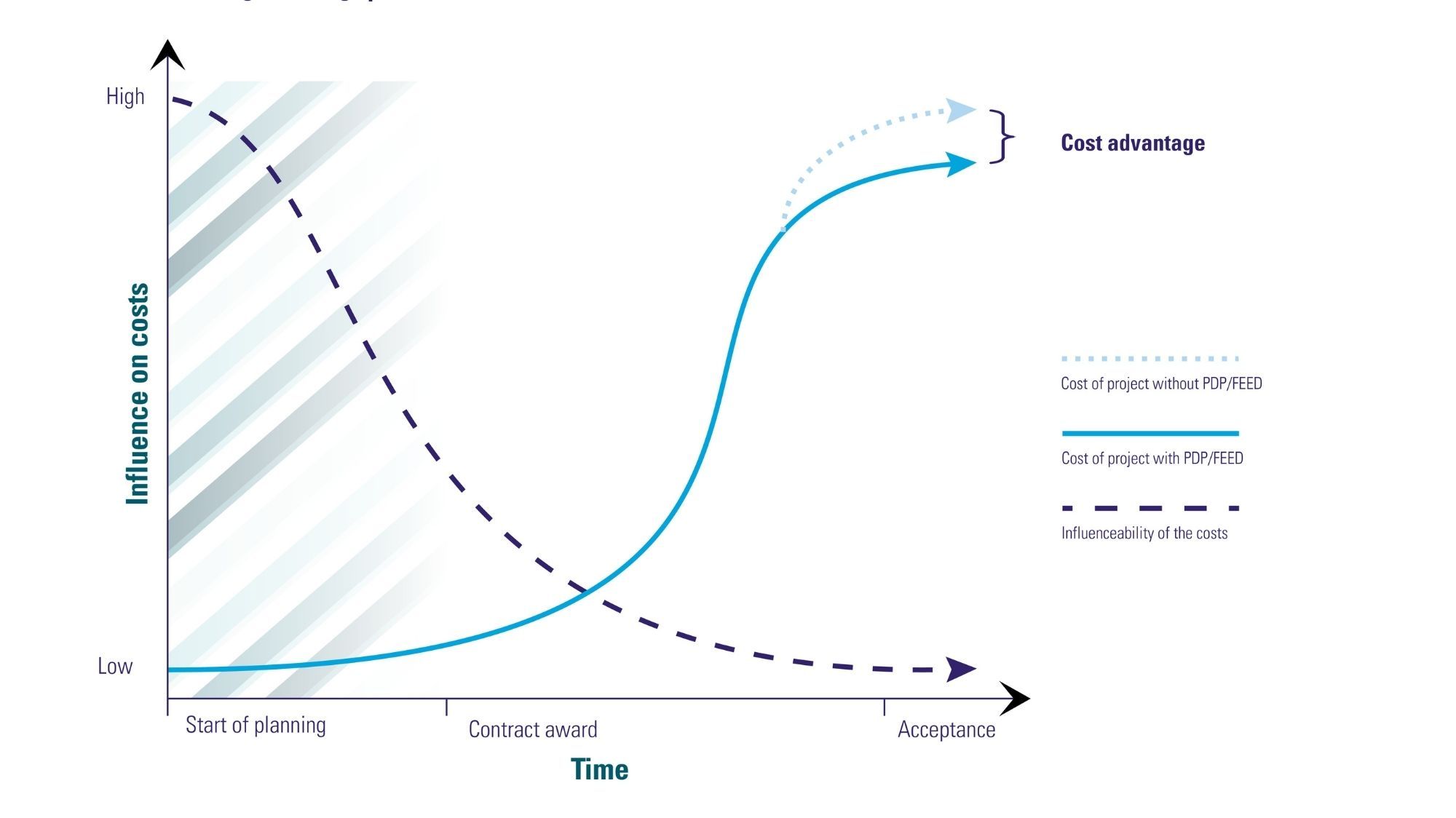

Zeppelin Systems Value Engineering optimizes planning processes, saving time and costs. We intervene at a stage where project costs can still be effectively influenced – during the initiation phase. For this, FEL (Front-End Loading) is implemented stepwise into the project development process, concluding with Basic Engineering or the project tender. Zeppelin Systems offers the necessary expertise and engineering services for all FEL phases, allowing your project to be optimized at any stage. Our FEL phase modules are divided into three stages:

- Feasibility Evaluation – FEL 1

- Preliminary Design – FEL 2

- Basic Engineering – FEL 3

FEL 1 – Project Design Package (PDP)

Simulations and calculations form the basis for realistically estimating the expected costs.

Step 1 of FEL includes defining the main components and an initial assessment of heat and material balances. The result is a PFD (Process Flow Diagram) with process data for the main components. FEL 1 also produces a cost estimate for all components.

Project phases:

- PFD

- Simulation

- Concept development

- Cost estimation

FEL 2 – Front-End Engineering Design (FEED)

In the FEL Step 2 phase, the primary focus is on the technical realization of the plant.

In a general layout plan, the main components such as silos, mixers, blower/compressor stations, bagging systems, storage halls, and main pipelines are integrated. We prepare the necessary PFDs, determine energy requirements, and assist you with the sizing and specification of the main components.

Project phases:

- PFD

- Sizing of main components

- Specification of main components

- Energy requirements

- General layout plan

- Budget proposal

- Schedule planning

FEL 3 – Basic Engineering (BASIC)

The more accurately costs, volumes, schedules, efforts, etc. are recorded, the more efficiently a project can be advanced.

Zeppelin Systems supports you in all aspects of FEL Step 3, which marks the completion of Front-End Loading. In this phase, uncertainties are significantly reduced. Specifically, quantities, schedules, labor effort, and costs are recorded much more accurately. FEL 3 delivers, for example, the P&IDs for the project as well as other relevant documents necessary for plant realization.

Project phases:

- EMSR concept

- Construction execution

- Instrument specification

- P&ID

- Final layout and arrangement of the plant and main components

- Bill of materials

- Schedule planning

- Cost framework

Root-Cause-Analysis (RCA)

Your system is not performing satisfactorily, there are issues, or you want to optimize your plant? Then a deeper inspection of the system is necessary to analyze the problems.

With this service, we optimize your system, reduce costs, and address the root cause of problems rather than just treating the symptoms.

Our specialists support you on the path to an optimal system. Root Cause Analysis has proven to be highly effective, as it focuses not only on the symptoms but also uncovers the underlying causes. It is divided into the following steps:

- Step 1: Identify the factors of the incident (why, how, and when the problem occurs)

- Step 2: Capture symptoms through intensive data analysis

- Step 3: Outline the process flow and identify possible causes

- Step 4: Analyze the main cause

- Step 5: Understand and propose solutions

SILO STATIC LOAD

Safe silos – optimized material flow for maximum efficiency

Whether grain, building materials, or plastics, whether fine powders or granulates – silos protect all types of bulk materials. Yet the silo’s role in the overall process is often underestimated. Inadequate design and neglecting the mass flow frequently cause problems with feeding into subsequent conveying lines. Additionally, attention must be paid to silo statics and the behavior of the stored materials. We consider all these factors and prepare the silo statics in advance – ensuring your silos operate safely and efficiently for many years.

Need more details? Our contact person will be happy to assist you

Michael Pfrieger

Global Market Manager Sales Polyolefine

Zeppelin Systems SERVICES

Additional Services from Zeppelin Systems

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH