Mixing and Kneading

Mixing, Kneading, Coating, Bonding, Compounding – you name it, we do it!

In product manufacturing, different mixing tasks need to be addressed. Since 1956, Zeppelin Systems has set standards in mixing technology with its HENSCHEL and MTI brand mixers. Whether in the plastics, chemicals, paints and coatings, or food industries, we offer the perfect solution for your mixing task, including process, handling, and processing expertise.

The product portfolio of Zeppelin Systems includes high intensity mixers, cooling mixers, as well as heating/cooling mixer combinations, universal mixers, container mixers and laboratory mixers – all customized for your specific process. Additionally, we offer various mixing and homogenizing silos, as well as pre-mixers for different doughs and the continuous dough kneading system CODOS NT.

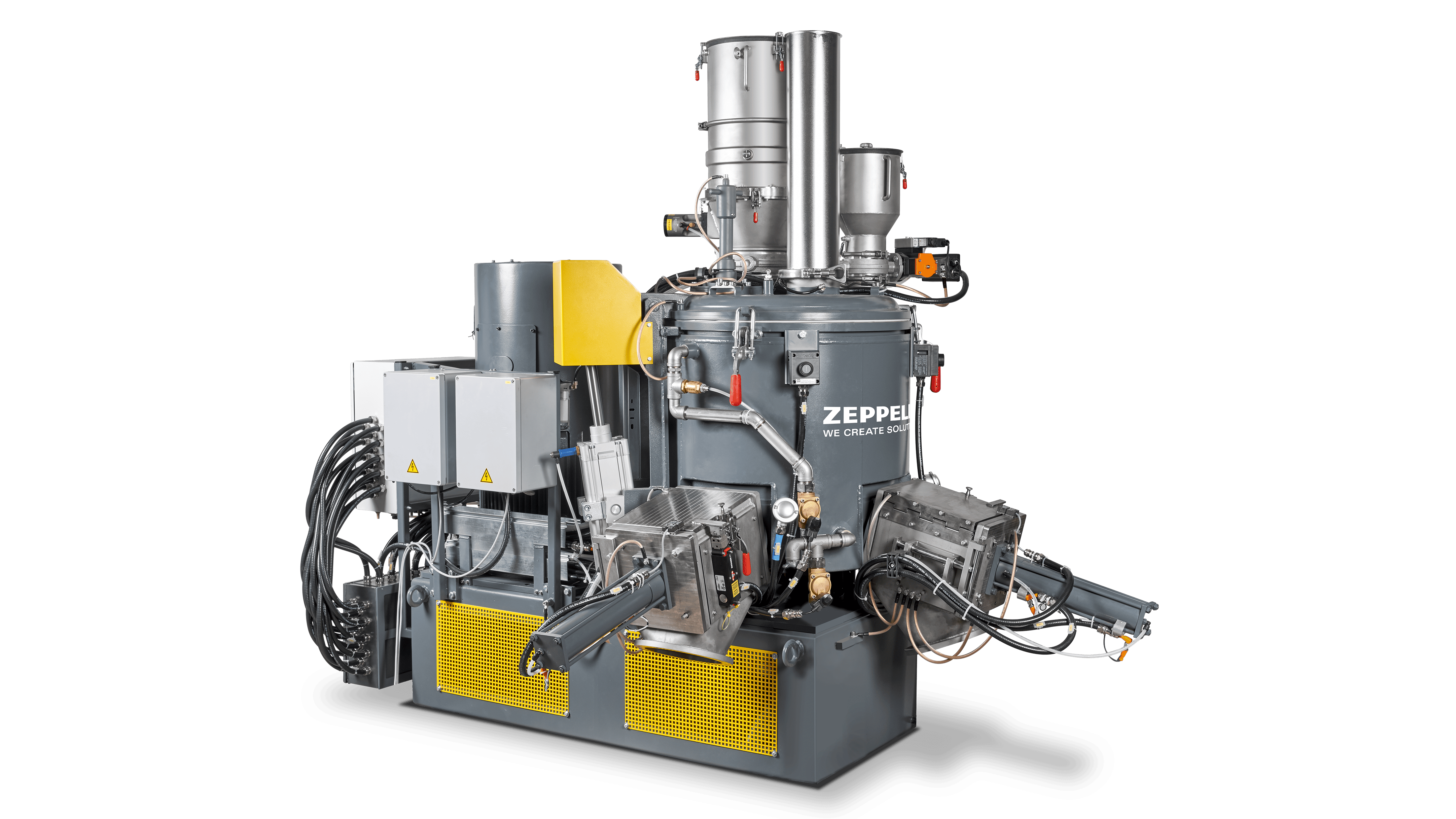

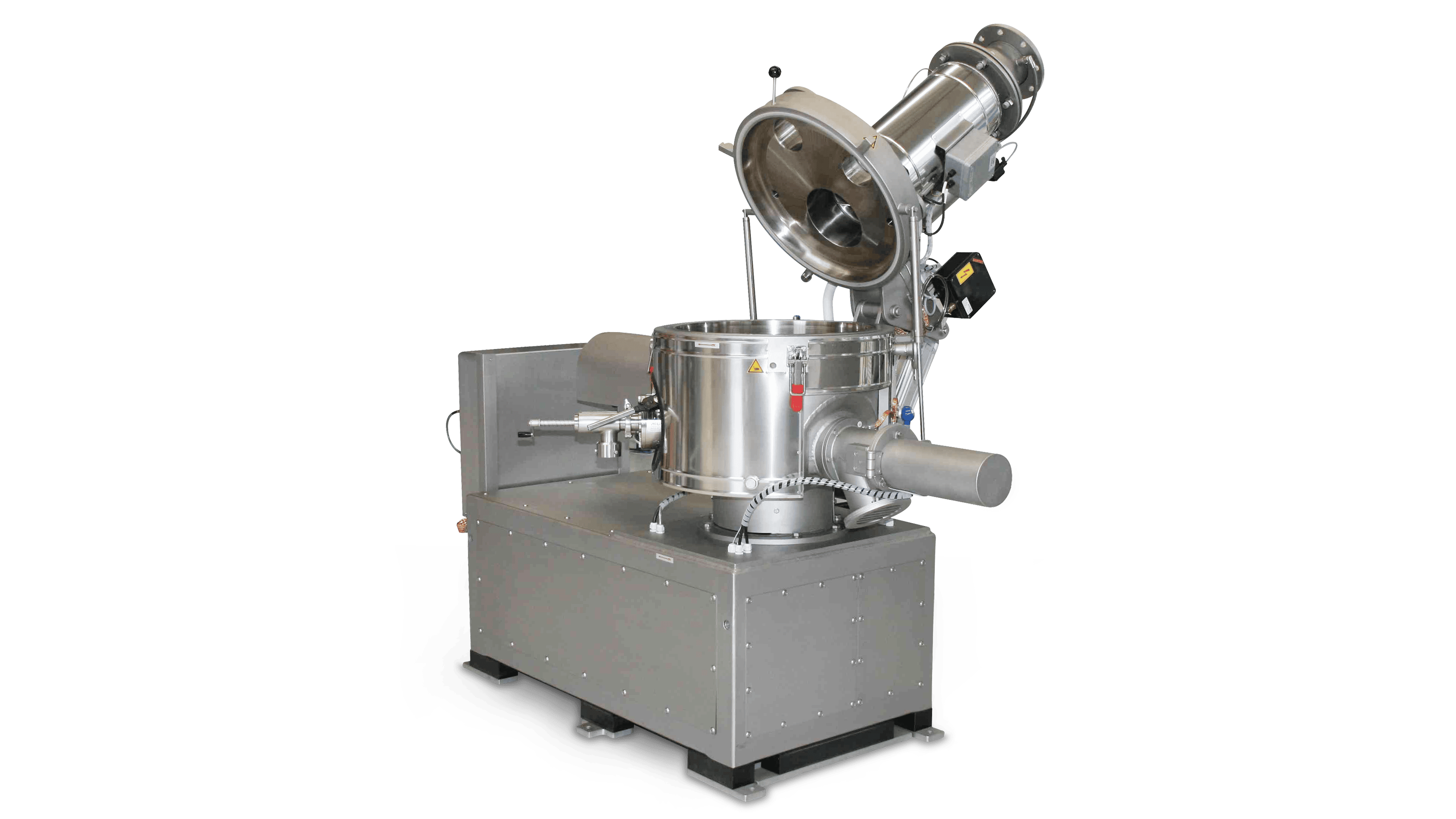

High-Intensity Mixers

Zeppelin Systems' high-intensity mixers stand for maximum efficiency and quality. Their fast-rotating mixing tools generate targeted heat through friction – ensuring optimal processing results. The exact amount of energy is applied as needed, while the material is treated with exceptional care.

Go to the High-Intensity Mixers

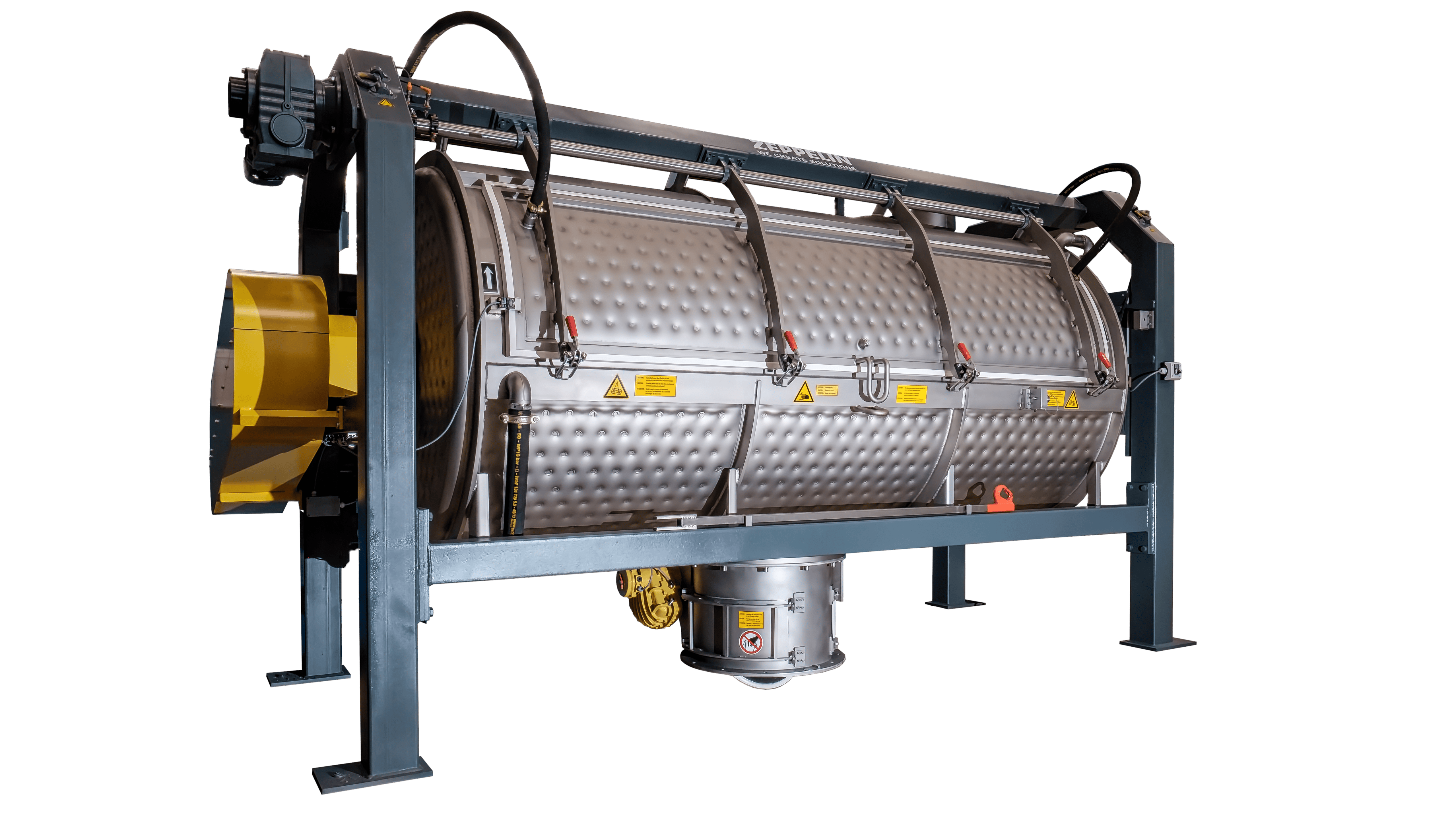

Cooling Mixers

Whether vertical, horizontal or modular – Zeppelin Systems’ cooling mixers deliver powerful solutions for fast, controlled cooling of bulk materials in the plastics and chemical industries. With smart cooling technology, high mixing performance and versatile applications, they ensure maximum efficiency – from PVC dryblend and compounding to technical plastics and WPC.

Go to the Cooling Mixers

Heating/Cooling Mixer Combinations

Zeppelin Systems heating/cooling mixer combinations for excellent product quality. Thanks to their intensive mixing action and effective aspiration, they ensure perfect dehumidification of the mix for optimum further processing.

Go to Heating/Cooling Mixer Combinations

Universal Mixers

Our universal mixers are a versatile solution for demanding process engineering tasks, whether with or without the addition of liquids. Thanks to their outstanding mixing performance, they process raw materials of different particle sizes and bulk densities in the shortest possible time - energy-efficiently and reliably.

Go to Universal Mixers

Container Mixers

Container mixers are universally applicable mixers for homogenizing, dispersing, and coloring all types of bulk materials. Unlike stationary mixer systems, the mixing container is mobile and can be filled and emptied independently of the mixing process. This allows contamination-free mixtures to be produced without the need for cleaning equipment parts and filling stations – for clean results and maximum efficiency.

Go to Container Mixer CMQ

Laboratory Mixers

Our laboratory mixers are the ideal solution for innovative developments, trial mixtures in laboratories and technical centres, and small-scale production. Processes such as mixing, coating, compounding, bonding and granulating bulk materials can be carried out reliably on a laboratory scale. This creates a secure basis for subsequent upscaling into production.

Go to Laboratory Mixers

CODOS® NT

Our continuous mixing and kneading system CODOS® NT delivers consistent dough quality and top performance – around the clock. The CODOS® NT always achieves consistently optimal results at any time. It excels in gently and intensively mixing both easily and poorly flowing dry materials, as well as liquids and pasty substances in the food sector, always in compliance with specific hygiene regulations.

Go to CODOS NT

DymoMix®

The DymoMix® works extremely fast, dust-free, and produces doughs with a homogeneous consistency. It rapidly moistens flour or other dry ingredients with liquids, applies air, and mixes them before they are introduced into the actual dough-making process. This results in doughs that can be used immediately or fed into batch kneading or continuous kneading systems. The DymoMix® is perfect for use in medium and large industrial operations, especially for pasta, waffle, and pre-doughs.

Go to DymoMix

Mixing Silos

In the production or recycling of plastics, achieving consistently high product quality can be challenging due to fluctuations in the process or raw materials. Here, gravity mixers make all the difference, as they significantly improve the quality of the end product. Our gravity mixers process large quantities of material with minimal recirculation to achieve a highly homogeneous mixture without additional energy input. This not only saves time and energy but also reduces dust generation. Our mixing silos are recognized by all licensors in the plastics processing industry.

Go to Mixing SilosApplication Areas

Industries

Plastics

Technical Plastics

Zeppelin Systems develops customized systems for technical plastics – from conveying to reactor integration. With many years of experience, we support you throughout the entire process: from planning and commissioning to service.

Go to technical plastics

Plastics

Compounding & Plastic Processing

Zeppelin Systems combines innovative technologies with decades of experience and over 10,000 reference plants – ensuring seamless processes from raw material management to packaging.

Go to compounding & plastic processing

Chemistry

Batteries

Zeppelin Systems develops customized, resource-efficient processes for battery slurry production – including a dedicated test environment to ensure optimal results.

Go to batteries

Chemistry

Dispersion Paints

With certified plant technology and comprehensive expertise, Zeppelin Systems offers maximum flexibility and safety across all processes in paint production.

Go to dispersion paintsNeed more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Zeppelin Services

Service

360˚ Service

Zeppelin Systems offers you service with real added value. We deliver not only turnkey plants, but also complete systems, mixers, silos, and components – and support you throughout the execution of your project.

Go to 360˚ services

Technology

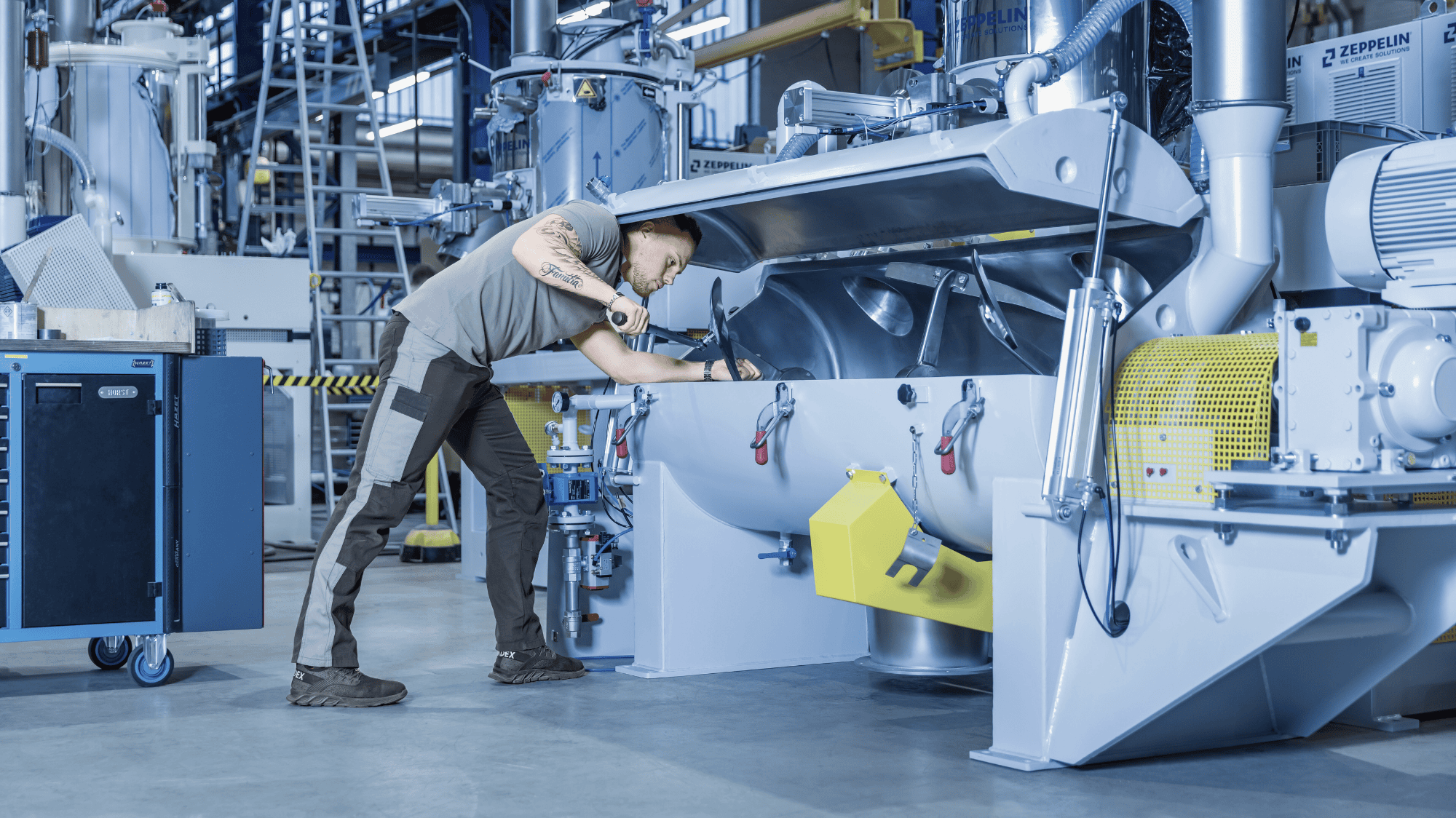

Technical Center for Mixing Technology

The technical center in Kassel offers the essential processes of mechanical engineering—in particular mixing technology—for the plastics processing and chemical industries. We develop new processes for processing and manufacturing sensitive raw materials for and in collaboration with our customers. Results can be immediately verified in our state-of-the-art laboratory.

Go to Technical Center for Mixing Technology

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutionsResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH