With Zeppelin Systems

Engineering and system integration at its finest!

We refine your raw materials to ensure they achieve the best possible properties for your market success!

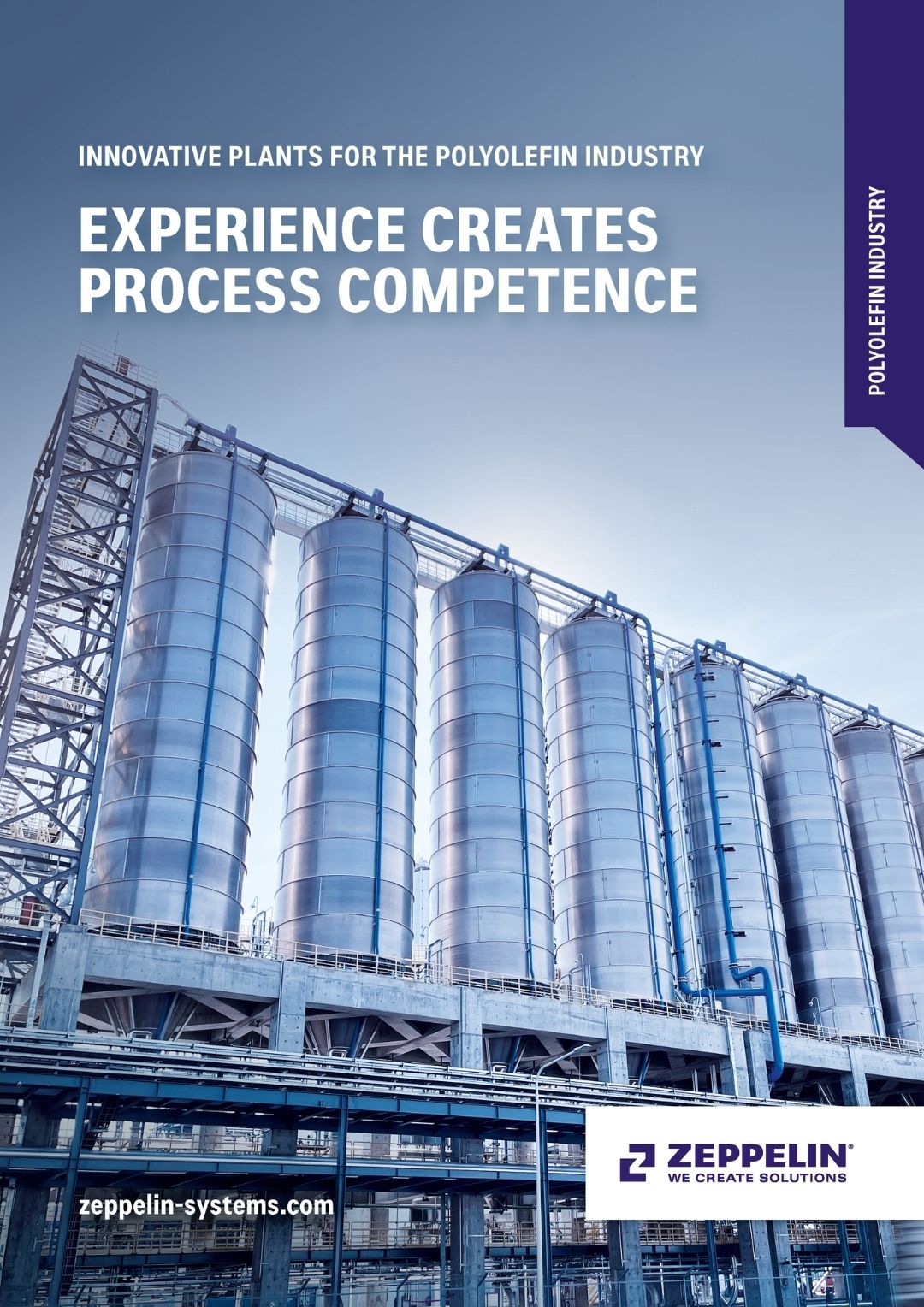

When it comes to the seamless integration of systems and components into the overall process in plastics manufacturing, Zeppelin Systems is unrivaled. We not only employ innovative methods and technologies but also draw on decades of plant-engineering experience and over 10,000 successfully installed reference plants worldwide. By producing our own silos, mixers, and key components, we enable an engineering approach free of interface issues. From flexible and reliable raw-material management, through diverse processing steps, to silo storage and final packaging, we deliver the optimal plant for your individual requirements.

Challenge in Compounding

Process machines such as extruders set the pace. All upstream and downstream units must operate faster to ensure the extruder can run continuously. That’s why every component must mesh perfectly. Need examples? Zeppelin Systems uses best-in-class mixing technology for additive pre-blends and premixes, and ensures complete emptying of silos, scales, and vessels. Even poorly flowing bulk materials are dosed with precision, and during conveying of raw materials and finished products, we ensure gentle handling and minimal abrasion.

Areas of application

Compounds and masterbatches based on

Polyolefins (PE and PP)

PVC-U, PVC-P, C-PVC, E-PVC

PA, PBT, ABS, SAN, etc.

TPE, TPU, TPV, etc.

PS, EPS, XPS, etc.

Oil-free polymers (e.g. PLA, starch) for bio-compounds

Benefits

Our advantages for the industry

Highest product quality

Highest product quality at maximum throughput

Range of applications

Covering a broad spectrum of formulations and applications

Product conveying

Gentle product conveying and precise dosing

Reliability

Reliable and reproducible production conditions

Flexibility

Flexibility and rapid cleaning during product changeovers

Plant availability

Continuous and reliable plant availability

Homogeneous production batches

Homogeneous production batches free of fines and angel hair

Worldwide service

Worldwide service and long-term spare-parts availability

Process steps

Insights into the compounding process

Engineering and planning

With Zeppelin Systems’ value engineering, we ensure optimal project management. From the initiation phase, we serve as your trusted partner, guiding you through Front-End Engineering & Design (FEED) with all relevant data for informed decision-making. From the creation of professional PFDs to the dimensioning and specification of all main components and the development of a complete 3D layout plan, we provide all planning details for your plant. In addition, we determine the energy requirements, prepare a demand-oriented schedule, and calculate a realistic budget price. This gives you a comprehensive decision-making basis, including all relevant CAPEX and OPEX figures.

Material reception and silo storage

We address varying packaging types and material characteristics at raw-material intake with a flexible, reliable raw-material management system. We ensure your bulk solids are stored economically, safely, and gently. Our silos — whether aluminum or stainless steel — prevent bridging and rat-holing with pneumatic or mechanical discharge aids, asymmetric flow zones, segregation, condensation, and air entrapment. We also comply with country-specific regulations, such as wind and seismic loads and explosion protection. Is your product or the production process new? We’ll determine all critical parameters in advance through shear tests at our in-house technical center.

Process or feedstock fluctuations can make it challenging to maintain consistently high product quality in plastics manufacturing or recycling. Our mixing silos compensate for these variations. Ensuring the right results when compounding and the quality of your products!

Material conveying systems and key components

Innovative conveying technologies guarantee gentle, uninterrupted transport—whether via pressure, vacuum, or mechanical screw conveyors. For special applications, we offer inflatable conveying hoses, vibratory rubber lines, PE piping, and an overflow system for bypass conveying. In short, we ensure safe material handling.

Zeppelin Systems’ rotary feeders provide reliable and consistent dosing of a wide range of bulk materials into pneumatic conveying systems. Our diverter valves distribute, collect, and direct any bulk material — powder, granulate, flakes, or other forms—to the correct destination.

Customers can also rely on us for liquid handling. Plasticizers, for example, can be tempered or melted on demand and supplied via flexible liquid-dosing systems. We also employ oil scales and volumetric multi-dosing units for closed-loop applications.

Filtration and screening

Whether PE, PP, glass-fiber-reinforced compound, or especially soft plastics such as LDPE with EVA – for every conveying challenge, there is a dedicated product-cleaning system: the perfect solution. Our modular filter systems also deliver optimal performance, featuring either antistatic filter cartridges or bags, and fully automatic pneumatic cleaning. This prevents material losses. By employing drum screens in downstream or subsequent process steps, we eliminate issues caused by agglomerates, overzize grain, etc. in plastic granulates.

Our sifters purify plastic granulates by separating out dust particles, fibers, and ‘angel hair,’ ensuring the highest possible granulate quality before packaging or loading.

Weighing and dosing

A wide variety of raw materials place the highest demands on extruders—especially on the dosing system. Requirements include absolute accuracy, contamination- and loss-free handling, and 24/7 availability. We integrate the optimal dosing system into your plant for a broad range of raw materials and additives, such as stabilizers, lubricants, plasticizers, colorants, fillers, flame retardants, crosslinking agents, blowing agents, or—for example—glass or carbon fibers to enhance stiffness, and mica for improved appearance. For small-component weighing, we’ve developed both innovative manual and automated solutions, with rapid-cleaning capability to support frequent recipe changes.

Mixing

Zeppelin Systems sets the standard with mixing systems in markets such as PVC, plastic compounds, paints, coatings and pigments, toner, mineral enhancement, and chemicals. To achieve this, we develop entirely new processes for handling and producing sensitive materials—both independently and in close collaboration with our customers. Why? Because truly efficient production lines—characterized by high availability and consistently reproducible product quality—are only possible with optimal system technology and processes precisely tailored to each product’s specific requirements. Our mixers deliver on this promise in both continuous-flow and batch-processing system configurations. Pre-mixing for dryblend, masterbatch, or additives on our equipment achieves the highest product quality at maximum throughput.

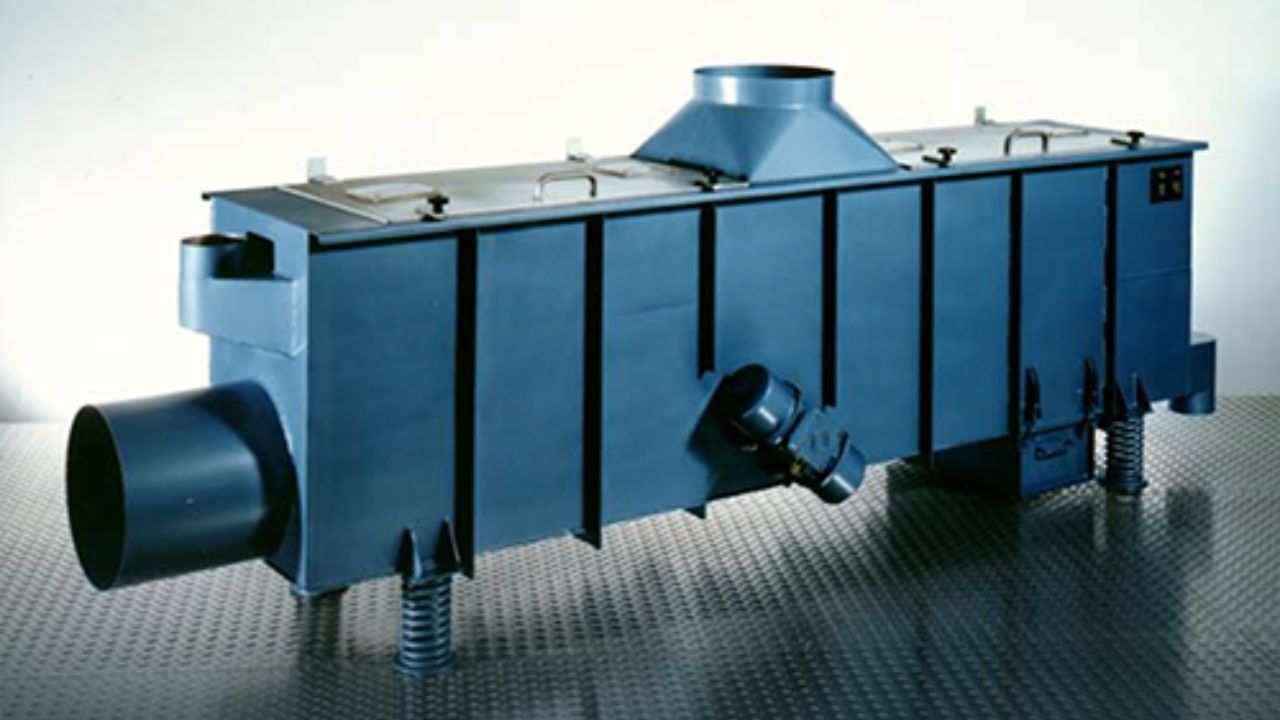

Granulate cooling

Our granulate cooling systems are distinguished by high throughput while maintaining low granulate temperatures. The residence time of the granulate is individually adjustable. Removable screen trays for separating oversized or undersized particles can be cleaned in no time. The granulate is pneumatically conveyed from a pelletizing unit to the cooler. It leaves the cooler at a temperature only slightly above that of the cooling air, allowing it to be stored or forwarded for further processing without risk of sticking together.

Electrical control

The provision of diverse raw materials requires first-class recipe management. Over 200 specialists in instrumentation, control, and automation configure the hardware, develop the software, and commission the plants on-site. The open, modular system architecture guarantees flexible adaptation for future requirements. Integrated within this are storage and recipe management, batch logging and material-consumption data, production planning, and batch traceability. From the field level through the control software to process and planning management with an MES, we connect our systems to the overarching ERP systems such as SAP or AVEVA.

Service and spare-parts availability

For us, the project certainly doesn’t end with the design of your plant! We guarantee first-class service and handle worldwide assembly and commissioning. We train your personnel—from expert instruction in process-engineering operations and proper maintenance to safe operation. We’re also here to help you establish safety standards. Routine maintenance, inspections and repairs, as well as a reliable spare-parts delivery service, are a given with us.

Need more details? Our contact person will be happy to assist you

Michael Pfrieger

Global Market Manager Sales Polyolefine

Services

Discover our comprehensive range of services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs — and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutions

Service

Service without compromise

In the 21st century, optimization often means automation. We ensure that your automation project is a complete success in terms of both efficiency and cost-effectiveness. To achieve this, we rely on cutting-edge control systems whose open architectures prepare you for the challenges of tomorrow—and beyond.

Go to servicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH