MicDos small component weighing

Automatic ingredient dosing for the smallest quantities

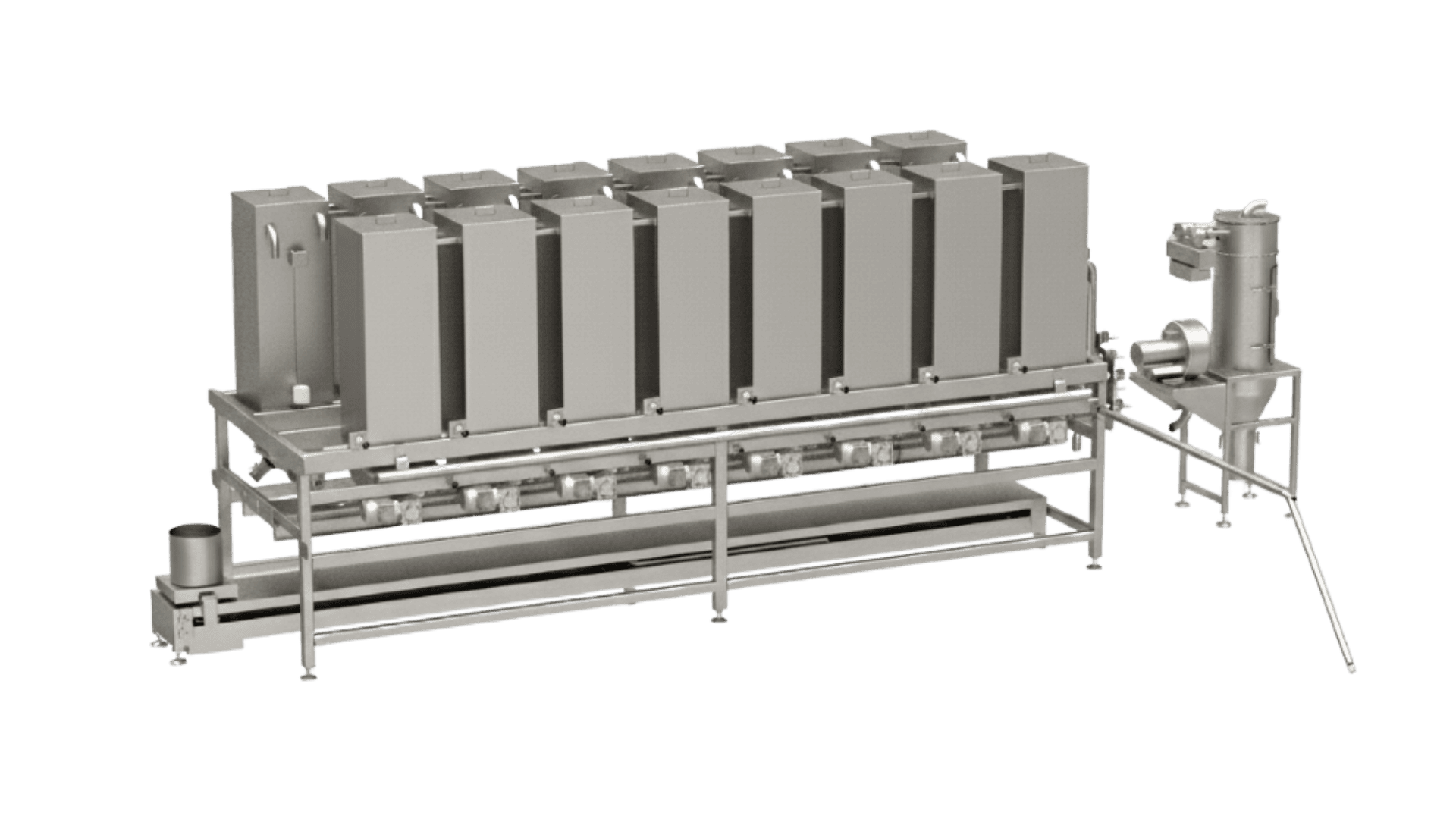

The MicDos (Micro Ingredients Dosing System) small component weighing system automates the handling of bulk material ingredients in the food, chemical, and pharmaceutical industries. The system is suitable for storing, sequential dosing, and highly precise weighing of up to 20 free-flowing to poor-flowing bulk materials. The modular design allows for recipe-controlled manual, semi-automatic, or fully automatic dosing and weighing of micro ingredient batches in a flexible linear layout. The main area of application is the food industry, with a growing trend toward industrial-scale ingredient systems integrated into fully automated large-scale plants.

Manual or fully automated solutions for small quantities

Depending on your requirements, number of components, and budget, we can offer you manual dosing stations as well as solutions for semi-automatic and fully automatic small component weighing:

- Fully automated solution: Sequential batch dosing from a hopper frame into a mobile hopper scale with subsequent batch transfer to a pressure conveying vessel and pneumatic transport into the production process.

- Semi-automated solution: Sequential batch dosing from a hopper frame into container on a mobile platform scale with manual batch removal.

- Manual solution (ManDos): Sequential manual batch dosing from a hopper frame into container on a table scale that can be moved along the rack.

Weighing systems tailored to your production

Reliable weighing and dosing of raw materials

The semi/fully automatic mobile scale (25 kg) is equipped with an aspiration hood and is suitable for both manual batch removal and pneumatic conveying with a pressure conveying vessel. Various configurations are available, including single or double row rack design. Bulk material hoppers with different volumes (250, 450 l) can be selected and optionally equipped with level indicator (HL/LL). Users also have flexibility when it comes to the discharge hoppers. Two types of dosing screws (DN50/80) are available, each with three drive sizes and different equipment options. Additionally, air injection nozzles can be integrated, and provisions can be made for the installation of pneumatic vibrators or impactors.

Product advantages

Our modular and compact system offers maximum flexibility and can be perfectly adapted to individual requirements. Thanks to the selectable degree of automation and the fully automatic dosing system, every process is designed to be efficient and reliable. The high dosing accuracy guarantees consistent quality, while the integrated recipe control allows easy and precise adaptation to different production requirements.

High dosing accuracy

- Dosing screw with frequency converter

- Coarse and fine flow

- Horizontal shut-off

- Overrun correction

Flexibility

Modular system with a wide range of options:

- Hopper sizes

- Filling and removal options

- Screw sizes

- Discharge aids

Safety

- No moving parts within reach

- Declaration of conformity according to MRL

- ATEX compliance

- EHEDG-compliant design

- Use of food-grade oils and lubricants

- EC 1935/2004 compliance

- Aspiration hood

Key facts at a glance

Focus on small quantities

Every production process is unique, and there is a wide range of ingredients that are only added to production in small quantities. Zeppelin therefore offers different versions of its proven MicDos small component weighing system for weighing and dosing

- < 20 batches/hour dosing capacity

- 1.8 - 25 l/min dosing screw throughput

- 0.23 m/s mobile scale speed

Sizes

4–20 hopper of 250–450 l each, 25 kg mobile scale

Application

Automated recipe-controlled dosing and weighing of free-flowing to poor-flowing bulk materials.

Pressure

Non-pressurized, -0.5 bar vacuum for pneumatic suction filling / suction conveying vessel, 1 bar overpressure for discharge via pressure conveying vessel.

Temperature

-10 to +50 °C

Materials

Parts in contact with the product made of V2A/V4A stainless steel, food/FDA-compliant seals.

Engine

Gear motor for dosing function and power adjustment.

Processes and applications

The precise solution for complex dosing tasks

The MicDos small component weighing system is used in various areas, particularly where several dry, powdered, and granular bulk materials need to be dosed in very small quantities and provided in batches, for example in a small-component dosing station for pre-dosing of:

- Baking aids and flavoring agents for bread and baked goods

- Spices for spice mixtures and soups

- Vitamins and additives for pet food

- Flavoring agents and additives for confectionery

- Additives for the chemical and rubber industries

Advantages for the industry

Food

No other company has such extensive experience in building modern plants for food technology. The foundation for our success? We make no compromises. It's not just the bakery and confectionery industry that values our comprehensive expertise in raw material handling: from raw material intake and storage to discharge, conveying, processing, dosing, and mixing and control.

Go to food industry

Rubber & Tire

Worldwide, we have already completed over 500 projects for the rubber and tire industry – from individual silos to fully turnkey plants. Our well-designed solutions provide measurable advantages across the entire value chain, all the way to recycling. We consistently focus on excellence in terms of material selection, technology, durability, and service.

Go to rubber & tire industry

Plastics

We design each Zeppelin system for plastic processing according to your specific customer requirements. You benefit from our decades of experience and our own innovative processes and technologies developed for the industry.

Go to plastics industryWould you like more details? Our contact persons will be happy to assist you.

Ingo Pütz

Global Market Manager Sales Food Processing Plants

Related products

Complementary products for an optimised process chain

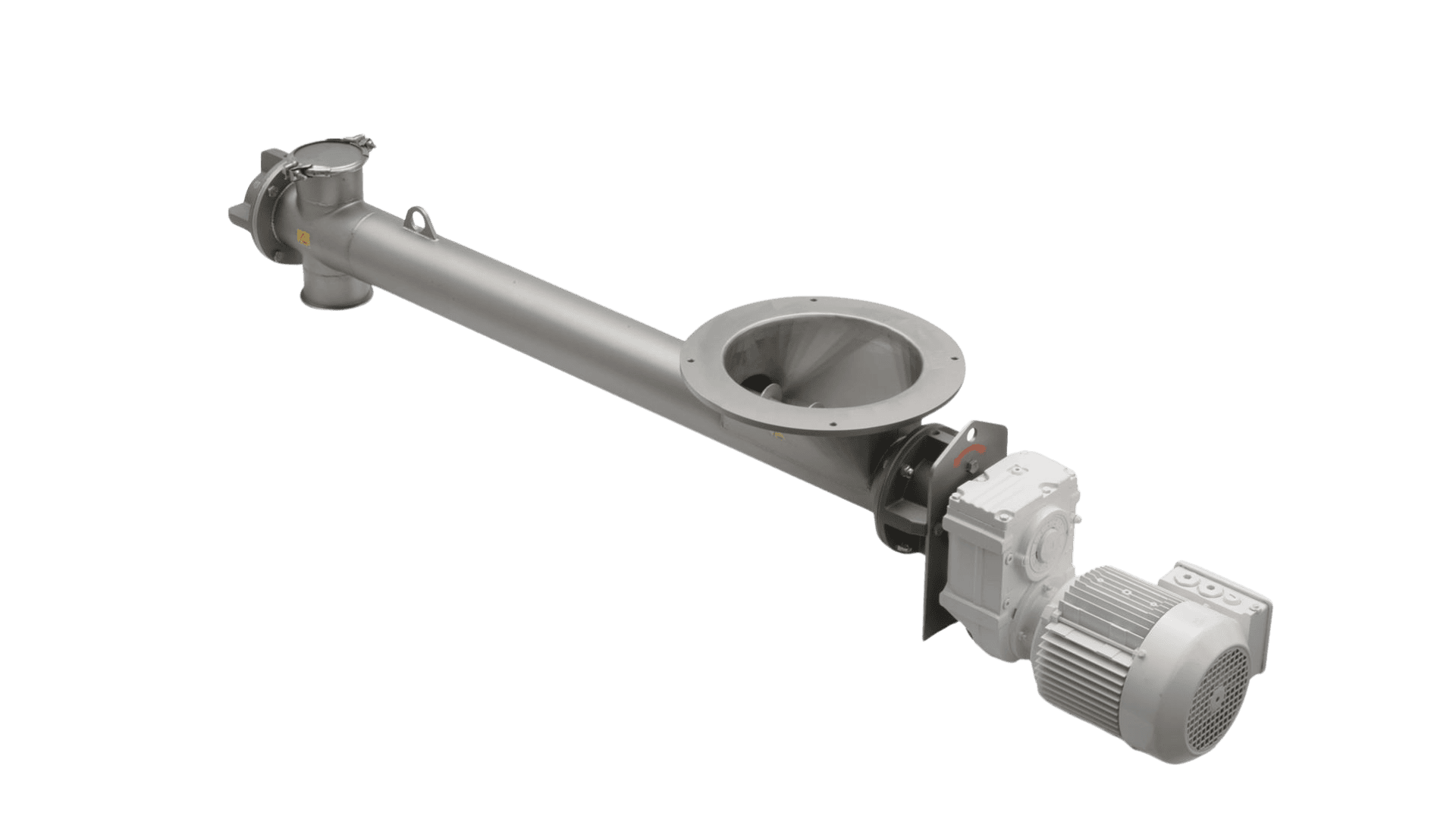

Dosing and Conveying Screws

When it comes to the smooth dosing of dry, powdery, and granular bulk materials, our dosing and conveying screws come into play.

Go to Dosing & Conveying Screws

KOKEISL Discharge and Dosing Module

Reliable discharge and precise dosing become effortless with the mechanical discharge and dosing module KOKEISL. A wide variety of bulk materials can be transferred in any quantity with extremely high throughput accuracy from silos and containers into other vessels.

Go to Discharge Modules

Flexible Container Scale HSF

The flexible hopper scale HSF is primarily used for fully automatic weighing of powdered bulk materials such as carbon black and silica, but it is also a good choice for granules.

Go to Flexible Container ScaleOur Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH