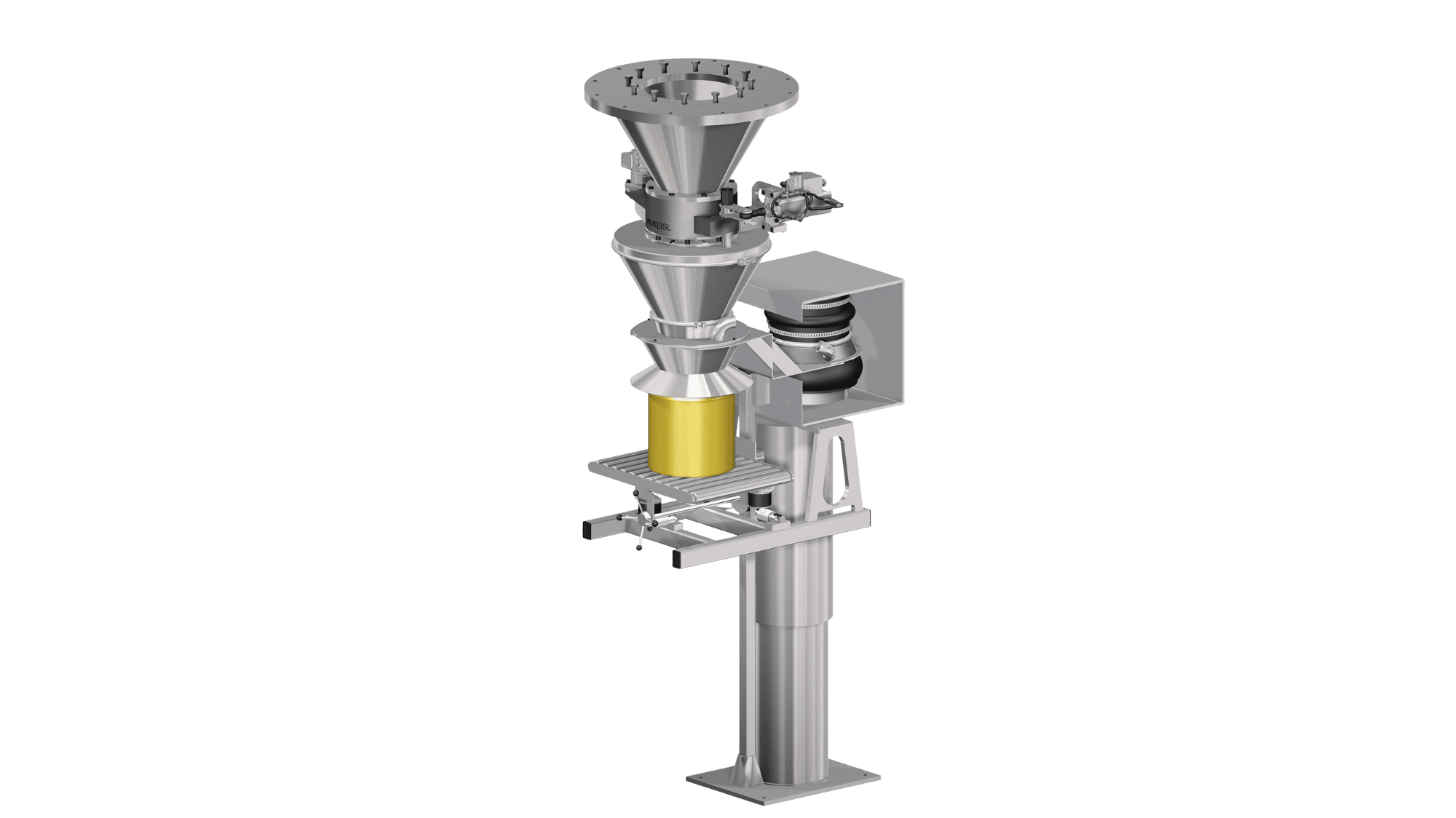

Discharge & Dosing Module KOKEISL by Zeppelin Systems

Precision Meets Flexibility

Discharging and dosing of even poorly flowing bulk materials

Reliable discharge and precise dosing become effortless with the mechanical discharge and dosing module KOKEISL from Zeppelin Systems. Thanks to the high flexibility of the system, any quantity of various bulk materials can be discharged from containers, big bags, or silos with high accuracy and throughput.

Conventional dosing and discharge mechanisms often fail with poorly flowing bulk materials. This is where the KOKEISL comes into play as an attractive alternative. The specially designed KOKEISL fluidizer rotates close to the cone's inner wall, preventing bridging. At the same time, the bulk material is loosened and gently discharged using its own gravity. A pivoting slide valve below the fluidizer acts as a closure and flow control (dosing). The discharge capacity can be continuously adjusted depending on the dosing method. With three available sizes, the system covers a wide throughput range from 0–10 / 0–25 / 0–45 m³/h.

Your Main Advantages at a Glance

High Flexibility and Rapid Dosing Cycles

Quick adjustment of the discharge opening via the pivoting slide valve (large coarse-to-fine flow ratio of 1:25,000).

Reliable Discharge

Loosening and prevention of bridging through the fluidizer; in most cases, no additional discharge aid is required.

Precise Dosing

Accuracy of +/- 1g, depending on the bulk material, installation situation, and available weighing resolution.

Integrated closure

No Additional End Cap Required (KAD): The pivoting slide valve serves as both a closure and dosing component.

Easy to Clean and Maintain (WIP-capable)

Made of few components, the dosing slide can be easily disassembled; new design with ball bearings.

Better Space/Performance Ratio

Compared to dosing screws (and other dosing mechanisms) with the same performance, discharge and dosing are accomplished with one component.

Safety

No movable parts are accessible; installation and conformity declarations according to MRL, CE – type approval certificate & ATEX conformity certificate 2014/34/EU; EHEDG-compliant construction with food-grade oils and lubricants, suitable for contact with food according to EC 1935/2004; speed monitoring.

The KOKEISL Discharge and Dosing Module Types by Zeppelin Systems

KA Discharge Module

The specially designed fluidizer rotates at a constant speed near the cone's inner wall, preventing bridging. This allows even poorly flowing bulk materials to be discharged. At the same time, the bulk material is loosened and gently discharged due to its own gravity.

KAD Discharge and Dosing Module

The wide dosing performance range (large coarse-to-fine flow ratio) enables quick product changes combined with flexible filling volumes. The pivoting slide valve, which operates freely, serves both as a closure and as a dosing component. The combined fluidizer ensures even product discharge, even for poorly flowing bulk materials, and can be used for both manual and automatic gravimetric (GiW) or volumetric (LiW) weighing processes.

Application Areas

Industries

The discharge and dosing modules can be used in many other industries. Feel free to contact us to discuss whether our KOKEISL modules are suitable for your application. We Create Solutions!

Food

Zeppelin systems offer precise dosing solutions for sensitive ingredients such as cornflakes, chocolate chips, or fruit pieces, as well as for spice blends, baby, and toddler food. The systems are suitable for applications with small components (MicDos), medium and large components, as well as the ReciPure® and FlexiDos container systems.

Go to food industry

Plastics

The materials used in plastics processing are becoming increasingly complex, for example, when considering fluffy materials such as film scraps in the recycling sector. However, we are able to process even these challenging materials and ensure they are safely transported for further processing.

Go to plastics industry

Rubber & Tire

In modern tire production, high standards are set for accuracy, reliability, and quality. The material flow must not be allowed to stall. Our discharge floors provide you with reliable support in this regard.

Go to rubber & tire industry

Chemistry

Things can sometimes get tough in the chemical industry. We make sure that you are on the safe side with our discharge floors. You benefit from our decades of experience, especially with regard to wear protection and explosion protection requirements.

Go to chemistry industryNeed more details? Our contact person will be happy to assist you

You Might Also Be Interested In

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH