Dosing and Conveying Screws from Zeppelin Systems

We've Got It Down!

The Right Screw for Your Application

The dosing and conveying screws from Zeppelin Systems are designed to dose and convey bulk materials of all kinds. They are also suitable for precise scale filling. The screws can be optimally adapted to the specific application. For example, a hygienic variant with quick cleaning is available for baby food production, as well as dust-tight versions for handling powders.

Zeppelin Systems’ screw portfolio provides the right solution for many dosing and conveying applications. The five sizes, with nominal diameters ranging from 80 mm to 300 mm for inlet and outlet, cover a wide range of dosing and conveying capacities, from very small to very large throughputs. The dosing function or performance can be adjusted via speed control.

Zeppelin Systems Dosier- und Förderschnecke

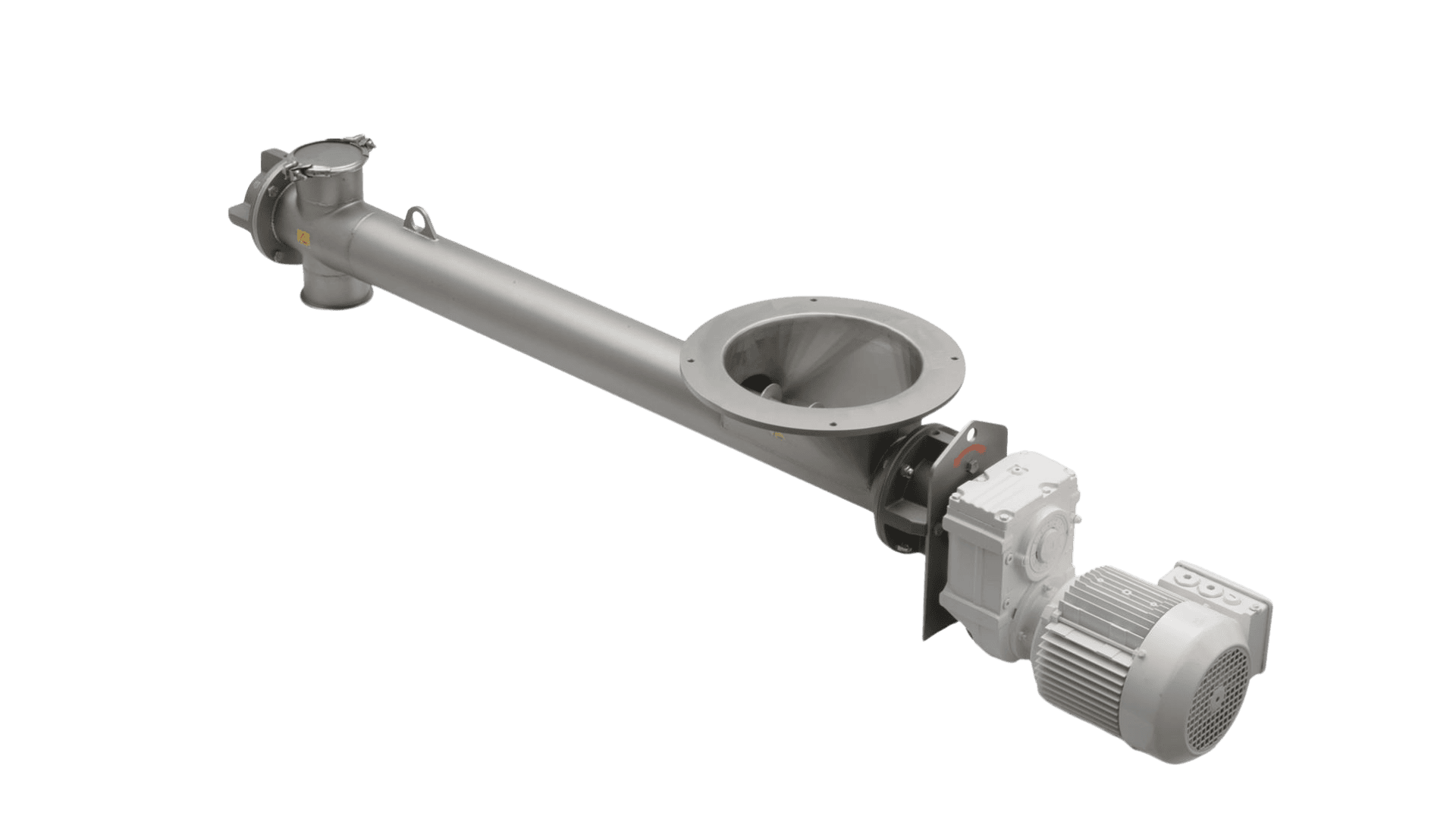

DOSING AND CONVEYING SCREW DS

The DS Dosing and Conveying Screw is used for dosing and conveying dry, powdery, and granular bulk materials, as well as for emptying containers. It is primarily used in conveying systems for dosing or filling scale containers and is available with one or two outlets. The screw is characterized by high dosing accuracy and flexible connection options. It comes in various sizes and can be adapted to specific requirements, such as handling abrasive products.

Benefits

Special Highlights

For Food & Tires

Food-grade design according to EHEDG, as well as the conveying of carbon black from tire recycling and fine bulk materials.

Hygiene Aspects

Easy cleaning with smooth exterior surfaces. Additionally, full access from the top ensures better cleaning and accessibility. Inspection openings guarantee easy access.

Performance Materials

High and flexible performance with high dosing accuracy (Chemicals, Battery Materials).

Process & Operational Safety

Easily dismountable for quick manual cleaning, no leakage, and dust-tight.

Key facts at a glance

- Sizes Available: Available in five sizes (80, 100, 150, 200, 300 mm) nominal diameter for inlet and outlet, with varying center distances between inlet and outlet in 50 mm increments, generally without intermediate bearings.

- Application: For powders and granules, with optional sealing gas system for very fine powders.

- Pressure Range: Operating pressure from -0.2 to 0.1 bar(g).

- Temperature Range: From -10 to +50°C.

- Materials: Housing made of aluminum, product-contacting surfaces made of stainless steel (complete stainless steel option available).

- Drive: Direct drive via a detachable gear motor, performance adjustment to local conditions (bulk material, bulk density, power, weighing accuracy, etc.) via a frequency converter installed by the customer.

Application Areas

Dosing and conveying screws in use across various industries

Our dosing and conveying screws are used wherever dry, powdery, and granular bulk materials need to be dosed and conveyed. They are ideal for dosing and filling scale containers, mixers, and kneaders, such as in batch processes for large, medium, and small components in the food industry, battery mass production, rubber & tire manufacturing, and plastic compounding. Additionally, the DS dosing and conveying screw is also used for emptying containers and silos, as well as for the constant conveying of main components.

Need more details? Our contact person will be happy to assist you

Related Products

Other products from the process step

Go to Conveying

Rotary feeders

The right rotary feeder for your application

Dosing, feeding, discharging – Rotary feeders from Zeppelin Systems keep bulk materials in motion. They ensure safe feeding into pneumatic conveying systems, relieve subsequent components under silos, and take on dosing tasks.

Go to rotary feeders

Discharge & Dosing Module KOKEISL

Precision Meets Flexibility

Reliable discharging and precise dosing become effortless with the mechanical discharge and dosing module KOKEISL from Zeppelin Systems. Thanks to the system's high flexibility, any amount of a wide range of bulk materials can be discharged from containers, bins, or Big Bags with high accuracy and throughput performance.

Go to discharge & dosing module KOKEISLOur Customer Services for You at a Glance

Show all Customer ServicesRessources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH