Rotary Feeders

that keep your process running

The Right Rotary Feeder for Your Application

Dosing, Feeding, Discharging – Rotary feeders by Zeppelin Systems keep bulk materials in motion. Rotary feeders from Zeppelin Systems ensure safe feeding into pneumatic conveying systems, discharge bulk material under silos and containers and perform dosing tasks.

The broad range of feeders from Zeppelin Systems offers the right solution for every application. This starts with small throughputs of 2.8 liters and goes up to volumes of 400 liters, covering pressures up to 3.5 bar(g) and temperatures up to 180°C. Additionally, Zeppelin Systems offers solutions for non-standard applications. For example, our process feederss cover a wide range of uses beyond typical pressures and temperatures, and models with crushing functions or quick cleaning options are also available.

Main Advantages at a Glance:

- High Purity and Less Waste: The optimized inlet and outlet geometry gently transports the bulk material through the airlock.

- Lower Energy Costs and Gas Consumption: Due to the optimal and individually adjusted gaps between the rotary airlock and the casing, the airlocks operate extremely energy-efficiently.

- Long Service Life, Extended Maintenance Intervals, and Low Repair Costs: Unique and durable sealing systems ensure long-lasting performance.

The Rotary Feeder Types from Zeppelin Systems

DFM Rotary Feeder

Medium pressure rotary feeder for the feeding and discharge of powders and granules in pneumatic suction and pressure conveying systems, which replaces the older rotary feeder models “A-type” & “AG/AP” with optimized features.

- Available in eight sizes: 160, 205, 240, 320, 360, 400, 500, and 630

- Can be used for powders and granulates, whereby a spiral can be provided in the inlet for granulates

- Operating pressure from -1.0 to 1.5 bar(g), mechanical design pressure from -1.0 to 10.0 bar(g), shock pressure resistant up to 10.0 bar(g)

- Mechanical temperature resistance from -20 to 90°C

- Housing and side plates optionally made of aluminum, stainless steel or iron casting

- Rotors optionally made of stainless steel or carbon steel

- Direct drive with drive train & motor

D-Type Rotary Feeder

Through-Flow Rotary Feeder, preferably for feeding powdery bulk materials into pneumatic conveying systems, wherein the bulk material is fed directly into the conveying line without a feed shoe

- Available in seven sizes: 160, 200, 250, 280, 320, 400, and 500

- Suitable for use with sticky powders or in confined spaces

- Operating pressure between -1.0 to 1.0 bar(g), mechanical design pressure from -1.0 to 10.0 bar(g), pressure shock resistant up to 10.0 bar(g)

- Mechanical temperature resistance from -10 to 60°C

- Housing and side plates made of high-quality cast aluminum hard-coated, stainless steel or iron casting

- Rotor with 10 chambers made of high-quality stainless steel or carbon steel

- Chain drive with drive train & motor

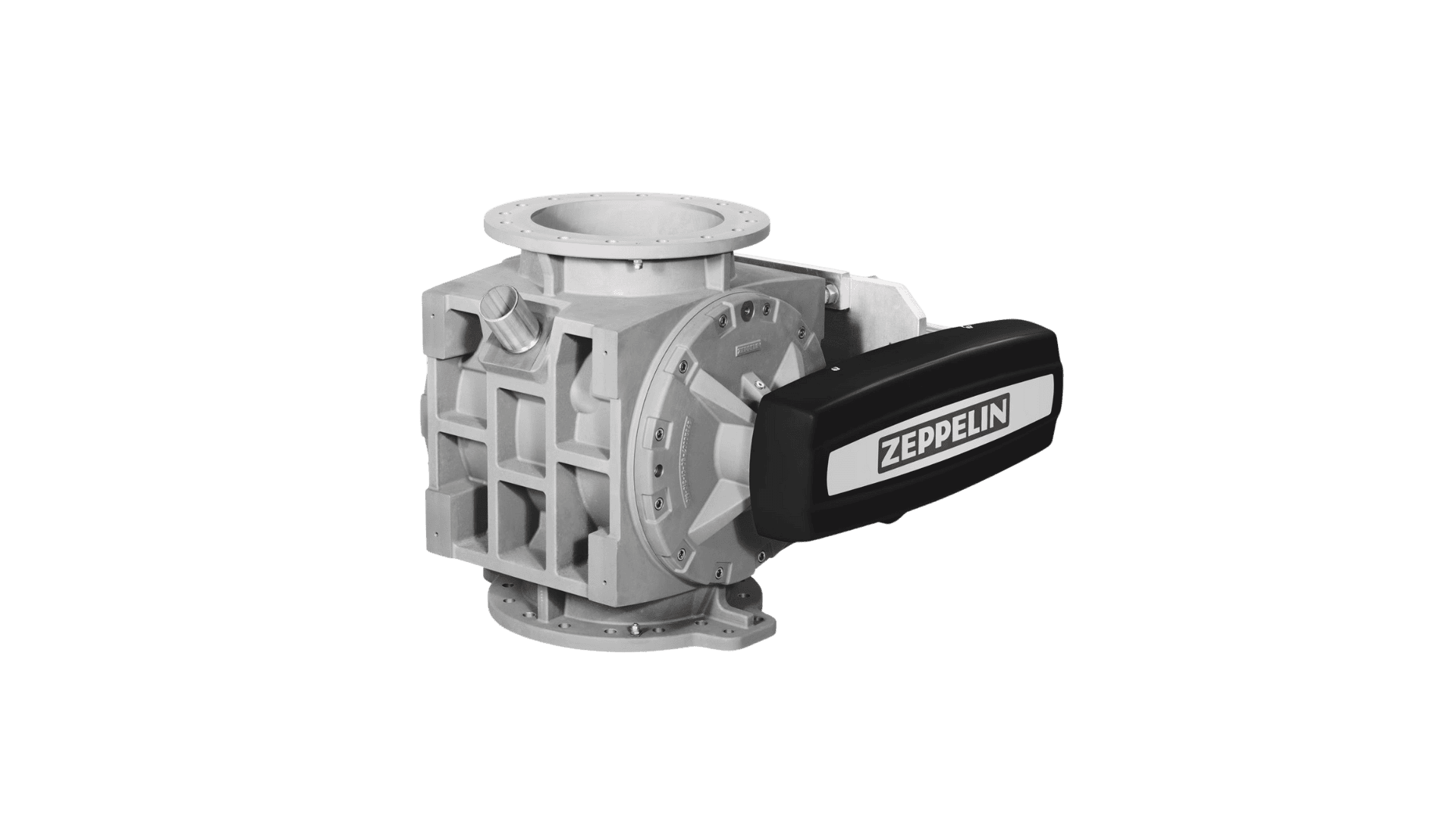

CFH Rotary Feeder

High-pressure rotary feeder, preferably for the feeding and discharge of bulk materials in pneumatic suction and pressure conveying systems. The rotary feeder can not only be operated at high pressures of up to 3.5 bar(g), but can also be used as a chopping or quick-cleaning version.

- Available in eight sizes: 200, 250, 320, 400, 500, 630, 750, 850

- Can be used for powders and granulates, whereby a baffle can be provided in the inlet for granulates

- Operating pressure from -1.0 to 3.5 bar(g), mechanical design pressure from -1.0 to 10.0 bar(g), pressure shock resistant up to 10.0 bar(g)

- Mechanical temperature resistance from -20 to +90°C

- Housing and side plate optionally made of aluminum or stainless steel

- Stainless steel rotors

- Chain drive with shaft & motor

CFM Rotary Feeder

Medium-Pressure Rotary Feeder, preferably for the feeding and discharge of bulk materials in pneumatic suction and pressure conveying systems

- Available in seven sizes: 200, 250, 320, 400, 500, 630, and 750

- Can be used for powders and granulates, whereby a baffle can be provided in the inlet for granulates

- Operating pressure from -1.0 to 1.5 bar(g), mechanical design pressure from -1.0 to 10.0 bar(g), pressure shock resistant up to 10.0 bar(g)

- Mechanical temperature resistance from -20 to +90°C

- Housing and side plate optionally made of aluminum or stainless steel

- Stainless steel rotors

- Chain drive with shaft & motor

PFC Process Rotary Feeder

Process Rotary Feeder is mainly used for feeding and/or discharging powders and agglomerates bellow discharge vessels. Thanks to its special design, the rotary feeder allows high torques and crush agglomerates.

- Available sizes: 565, 650, 750, 850

- Can be used for chopping or cutting agglomerates or solid, large components within a bulk material

- Operating pressure from -1.0 to 1.5 bar(g), mechanical design pressure from -1.0 to 10.0 bar(g), pressure shock resistant up to 10.0 bar(g)

- Mechanical temperature resistance from -20 to +120°C

- Housing and side plates made of aluminum

- Rotors made of stainless steel

- Direct drive with shaft & motor

Application Areas

Rotary Feeders in Use Across Various Industries

Need more details? Our contact person will be happy to assist you

Our Rotary Feeders are Used Across Various Industries

In addition to the examples provided, our rotary feeders can also be used in other industries. Feel free to contact us to discuss whether our airlocks can be applied to your specific application – We Create Solutions!

Food and Beverage

Typical applications include the feeding and discharge of flour and sugar in pneumatic conveying systems. Our rotary feeders also safely feed and discharge bulk materials in animal feed production. The sizes 160-320 feature particularly narrow gaps to reduce leakage. All plastic seals are food-grade certified.

Plastics

With our rotary feeders, a wide variety of plastic powders and granules, such as polyolefins, compounds, and engineering plastics, are fed in and discharged to subsequent systems. The different variants are precisely tailored to your application. For example, there is a rotary feeder variant optimized for recycled plastics such as shreds, flakes, or film scraps. For very soft or very hard granules, an inlet variant with a spill plate is available. Our process rotary feeders are designed with high to very high torque capacities to ensure a crushing function.

Chemistry

In this industry, the biggest challenges lie in handling powders. For example, there are abrasive bulk materials that range from easy to difficult flowability. Special surface coatings are available to address this. Additionally, a quick-cleaning variant is offered to avoid contamination between different products.

Rubber & Tire

In tire manufacturing, in addition to base materials like carbon black and silica, many other additives are used. Zeppelin Systems rotary feeders ensure optimal feeding of these materials into pneumatic conveyance systems with bypass systems and safe discharge of additives. A sealing gas system protects the bearings from ingress of bulk materials. For high pressures, high-pressure rotary feeders with closed rotary airlocks are used.

Related Products

Other Products from the Process Step

Go to Conveying

Valves

Set the Direction!

Our diverters are designed for long-lasting durability and are exceptionally reliable. The range extends from cost-effective standard solutions to custom-made options – in any case, we know the right direction. Various designs, surface finishes, materials, and seals are available to meet your specific needs.

Go to valves

Sampler

Safe Sampling for the Highest Product Quality

When it comes to securing the production process, or evaluating the quality of the final product, representative samples of the bulk material must be taken. Sample takers from Zeppelin Systems provide safe sampling of flowable powdered or granular bulk materials from silos, containers, downpipes, or pneumatic conveying systems. The sample can be taken under normal atmospheric conditions or within a pressure range up to 1 bar(g).

Go to samplers

Dosing & Conveying screws

We've Got It Down!

The dosing and conveying screws from Zeppelin Systems dose and transport bulk materials of all kinds. Additionally, they are also suitable for precise scale filling. The screws can be optimally adapted to the specific application. For example, a hygienic version with quick cleaning is available for baby food production, as well as dust-tight versions for handling powders.

Go to dosing & conveying screwsOur Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH