Diverter Valves from Zeppelin Systems

Set the Direction!

The Right Diverter Valve for Your Application

Our diverter valves are designed for long durability and exceptional reliability!

The range extends from cost-effective standard solutions to custom-made options – in every case, we know the right direction. Various designs, materials, and sealing options are available.

The Zeppelin Systems diverter valve portfolio offers the right solution for every application. The selection depends on the size of the connected pneumatic conveying line, the maximum occurring conveying pressures, and the properties of the bulk material being conveyed. Diverter valves can be designed as distribution diverters or collection diverters. Whether dealing with high-purity plastic granules, powdered food materials, sticky pigments, or highly abrasive mineral bulk materials, Zeppelin Systems provides the perfect diverter valve. We choose materials and sealing materials based on the application, always focusing on long-lasting and reliable operation. You can rely on our diverter valves!

Key Advantages at a Glance:

- High Purity and Less Waste: Optimized inlet and outlet geometries ensure gentle material handling through the diverter.

- Lower Energy and Gas Consumption: Due to optimal and individually tailored sealing systems between the rotor and housing.

- Long Service Life, Extended Maintenance Intervals, and Low Repair Costs: Achieved through the selection of suitable materials and reliable sealing systems.

- No Material Carryover: Thanks to a dead-space-free internal geometry.

Our components are certified, and in specific cases, also country-specific certified

The Diverter Valve Types from Zeppelin Systems

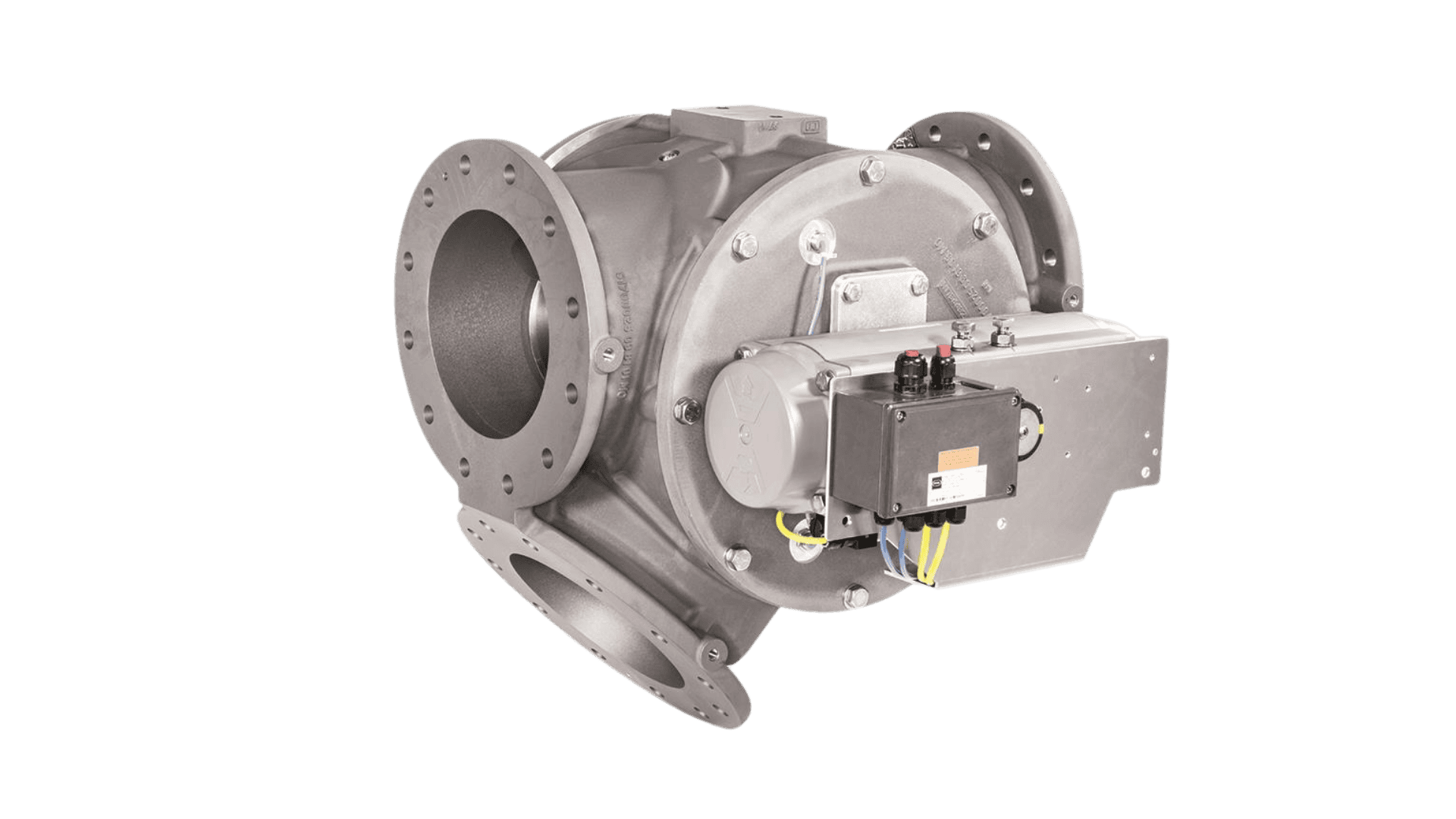

VST & TST Diverter Valve

For the Steering of Bulk Material Flow in Pneumatic Dense Phase and Dilute Phase Conveying Systems

Thanks to the patented geometric design of the interior rotor and housing, it can be used in any conveying direction. The VST has a deflection angle of 45°, while the nearly identical TST diverter has a deflection angle of 90°.

- Sizes Available: 100, 125, 150, 185, 200, 230, 250, 300, 350, 400

- Application: For powders and granules

- Pressure Range: Operating pressure from -1.0 to 6 bar(g), pressure shock resistant up to 10.0 bar(g)

- Temperature Range: Mechanical temperature resistance from -20 to 120°C

ZWR Single-Channel Pipe Diverter

For Steering the Bulk Material Flow in Pneumatic Dense Phase and Dilute Phase Conveying Systems

The ZWR Diverter has a deflection angle of 35°. The conveying direction is determined at the time of ordering

- Sizes Available: 50, 65, 80, 100, 125, 150, 200, 250

- Application: Primarily for abrasive, powdered, and granular bulk materials

- Pressure Range: Operating pressure from -1.0 to 6 bar(g), pressure shock resistant up to 10.0 bar(g)

- Temperature Range: Mechanical temperature resistance from -10 to 80°C

DVV Dual-Channel Pipe Diverter

For Steering the Bulk Material Flow in Pneumatic Dense Phase and Dilute Phase Conveying Systems

The DVV Diverter has a deflection angle of 35°. It can be used in any conveying direction.

- Sizes Available: 50, 65, 80, 100, 125

- Application: Primarily for powdered and granular bulk materials in the food and plastics industries

- Pressure Range: Operating pressure from -0.5 to 3.5 bar(g), pressure shock resistant up to 10.0 bar(g)

- Temperature Range: Mechanical temperature resistance from -20 to 120°C

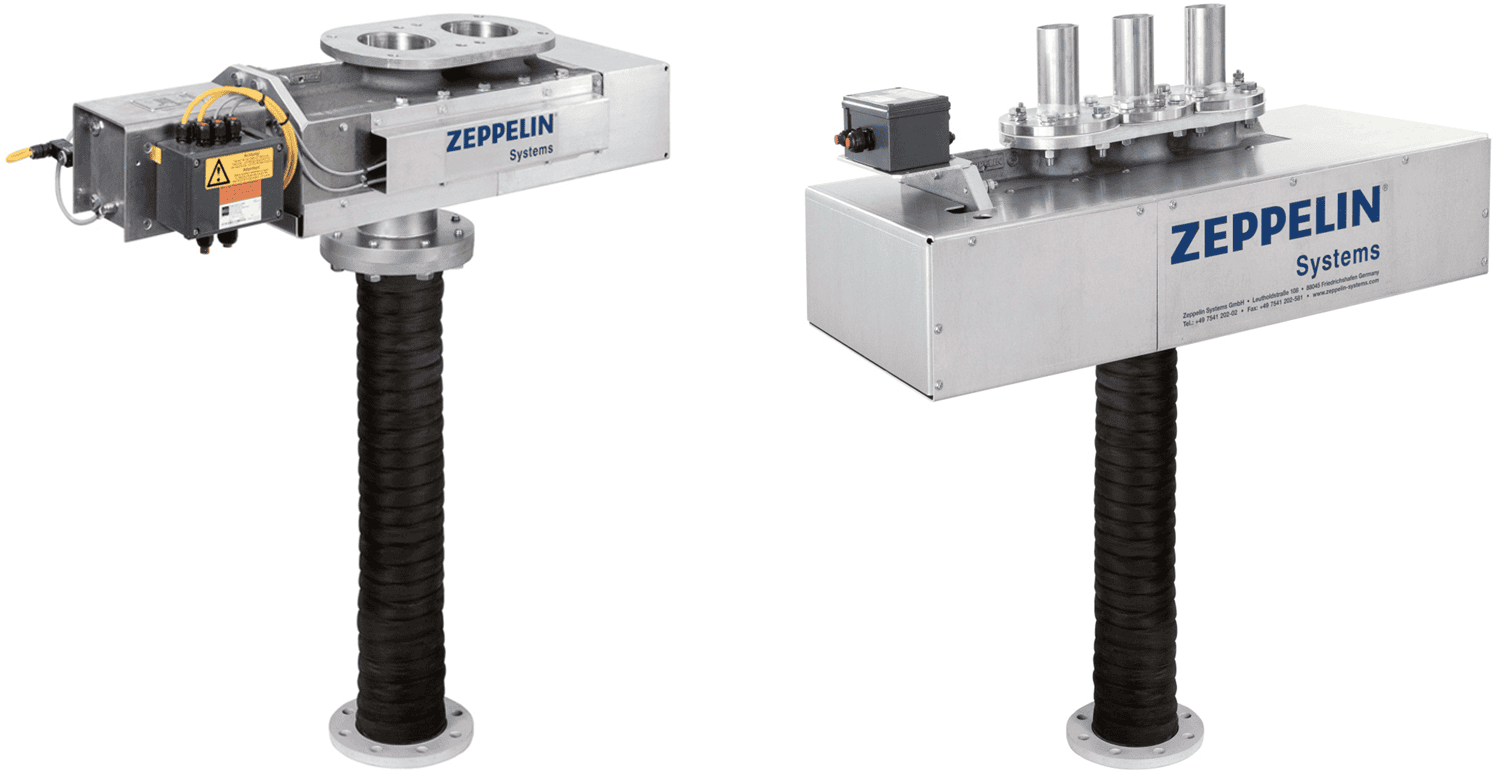

ZWS Two-Way & DWS Three-Way Hose Diverter

For Steering the Flow of Cohesive Bulk Materials in Pneumatic Dense Phase and Dilute Phase Conveying Systems

The ZWS Two-Way Hose Diverter and DWS Three-Way Hose Diverter are primarily used for steering the bulk material flow in pneumatic dense phase and dilute phase conveying systems. These can be used in any conveying direction.

- Sizes Available: 50, 65, 80, 100, 125, 150, 175, 200, 225

- Application: Due to the flexible hoses, this diverter is particularly suitable for cohesive powdered and granular bulk materials in various industries.

- Pressure Range: Operating pressure from 0.0 to 0.8 bar(g) (Standard)

- Temperature Range: Mechanical temperature resistance from -10 to 80°C

Application Areas

Diverter Valves in Use Across Various Industries

Need more details? Our contact person will be happy to assist you

Our diverter valves are used in various industries

In addition to the following examples, our diverter valves can also be used in other industries. Feel free to contact us to discuss whether our diverter valves can be used for your application - We Create Solutions!

Food and Beverage

Typical applications include steering bulk material flows such as flour, sugar, and salt in downpipes or pneumatic conveying systems. Various bulk materials in the animal feed sector and other applications are also directed using the diverter valves. Special attention is given to good cleanability and minimal material carryover:

- Seals made of plastic therefore have the appropriate food-grade certification.

- In the food industry, all product-contacting surfaces are generally made of stainless steel.

Plastics

Plastic powders and granules, such as polyolefins, compounds, and engineering plastics, are conveyed and redirected into different directions using diverter valves. To ensure this happens as gently as possible without abrasion, Zeppelin Systems offers interesting variants:

- For high-quality powdered or granular bulk materials, various sealing options are available.

- Shock-free internal contours prevent unwanted material stresses that could cause abrasion in the form of powder or angel hair.

- Generally, the interior rotors in pipe diverter valves feature a stainless steel pipe insert. The flange necks of the pipe diverter housings can also be equipped with stainless steel pipe inserts upon request.

- Additional weatherproof covers, with or without heating, allow the use of pipe diverter valves even at extremely low ambient temperatures.

Chemistry

In this industry, handling powders, which can range from easily to difficultly flowable and often abrasive bulk materials, can be challenging. However, Zeppelin Systems offers numerous solutions to safely guide even the most demanding products in the right direction.

- For very abrasive bulk materials, inflatable seals are available.

- In certain applications, additional purge gas units prevent powdered, abrasive materials from settling between the interior rotor (rotor) and housing in the sealing area.

- For highly abrasive materials, diverters with hardened stainless steel pipe inserts or diverter valves with ceramic lining are also available.

- The sticking of very sticky bulk materials, such as pigments, can reliably be prevented with flexible hose diverters.

- When using seals on the inside of the housing, all three pipe outlets can be sealed simultaneously. This also prevents reverse pressure on the non-activated pipe outlet.

Rubber & Tire

In tire manufacturing, the base materials are typically carbon black and silica, along with possible additional additives. Zeppelin diverters ensure reliable bulk material redirection in pneumatic conveying lines with bypass systems. There are various options available:

- For tire carbon blacks, aluminum castings, hard-coated as standard, are used for the diverter housing and interior rotor (rotor), which significantly reduces the adhesion of carbon black.

- Typically, gland packing seals are used as static seals on the interior rotor.

- For highly adhesive technical blacks (pigments), flexible hose diverters are also used.

Related Products

Other products from the process step

Go to Conveying

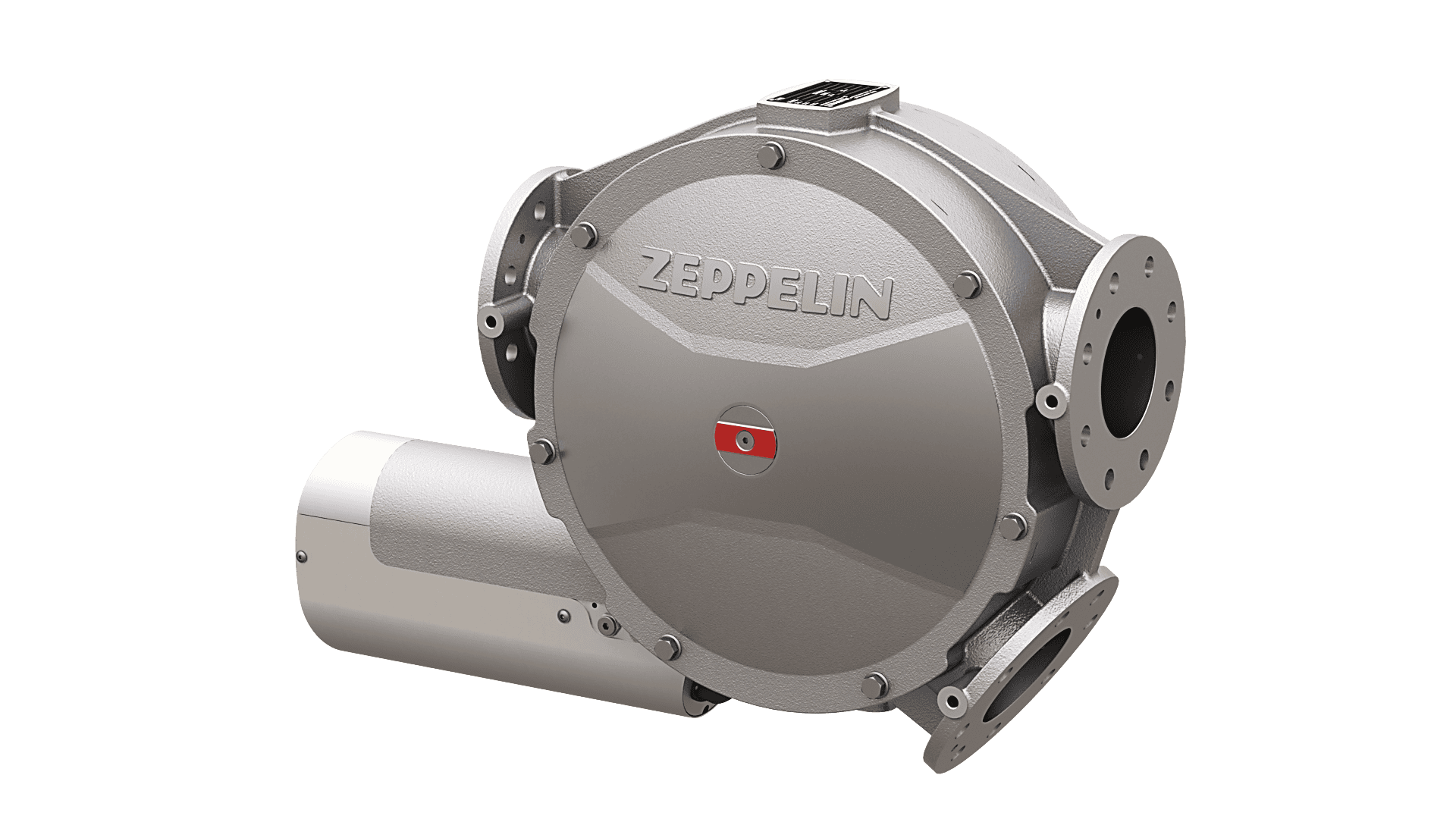

Rotary feeders

The right rotary feeder for your application

Dosing, feeding, discharging – Rotary feeders from Zeppelin Systems keep bulk materials in motion. They ensure safe feeding into pneumatic conveying systems, relieve subsequent components under silos, and take on dosing tasks.

Go to rotary feeders

Sampler

Safe Sampling for the Highest Product Quality

When it comes to securing the production process, or evaluating the quality of the final product, representative samples of the bulk material must be taken. Sample takers from Zeppelin Systems provide safe sampling of flowable powdered or granular bulk materials from silos, containers, downpipes, or pneumatic conveying systems. The sample can be taken under normal atmospheric conditions or within a pressure range up to 1 bar(g).

Go to samplers

Dosing & Conveying screws

We've Got It Down!

The dosing and conveying screws from Zeppelin Systems dose and transport bulk materials of all kinds. Additionally, they are also suitable for precise scale filling. The screws can be optimally adapted to the specific application. For example, a hygienic version with quick cleaning is available for baby food production, as well as dust-tight versions for handling powders.

Go to dosing & conveying screwsOur Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH