Conveying

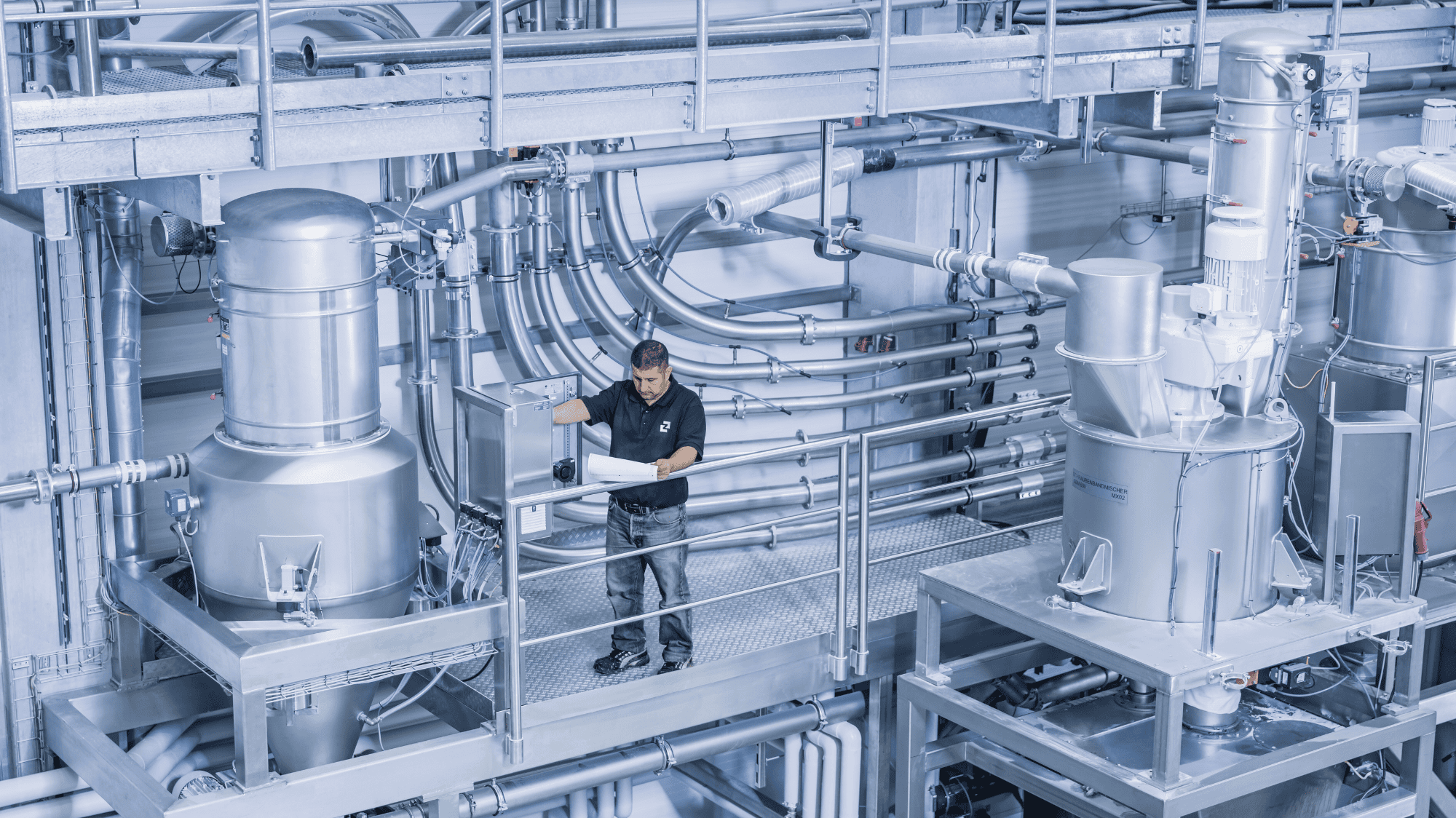

The Right Conveying System for Your Specific Requirements

Customized Conveying Solutions through Precise Bulk Material Analysis

Depending on the customer-specific requirements, different conveying methods are used. And to do so, it is crucial to fully understand the bulk material. That’s why we analyze the properties of your bulk material in advance, taking into account system parameters, the overall plant concept, as well as investment and operational costs. This ensures you get a conveying system precisely tailored to your needs, whether you're in the food, plastics, or rubber industry.

Rotary Feeders

Our rotary feeders are versatile, whether for discharging, feeding, or dosing bulk materials. They isolate different pressure areas from each other, are used for explosion decoupling, or break down larger agglomerates. But airlocks can do even more! Provided they are optimally matched to the application and bulk material. Whether powder or granules – our components impress with high fill levels, ideal sizes, product protection, innovative sealing systems, and minimal leakage – so rely on perfection!

Go to rotary feeders

Valves

Our diverters set the direction, whether straight or with a deflection of 30°, 45°, or 90°, as collection or distribution diverters. They are flexibly used for a wide range of bulk materials and applications, including low and high-pressure areas or for particularly high operating temperatures. Our sealing systems minimize maintenance work, and hardened inserts provide longer service life. Smooth transitions and very small dead zones prevent product carryover from one batch to the next. Moreover, gentle bulk material handling is our top priority. Rely on proven top quality and maximum efficiency in daily operations, ensuring that your products stay at their best during transport!

Go to valves

Dosing & Conveying screws

For mechanical conveying over short distances, as well as for discharging and dosing powdered and granular bulk materials, our screw conveyors have proven themselves in numerous applications. They are characterized by a robust construction, easy cleanability, and high dosing accuracy. Our pipe or trough screw conveyors can be flexibly adapted to your requirements and products.

Go to dosing & conveying screws

Sampler

Our sample takers allow you to safely extract flowable powdered or granular bulk materials from silos, containers, downpipes, or pneumatic conveying systems. Sampling can be done continuously or in batches. We offer two different types of samplers, ensuring that we provide the right solution for every application.

Go to samplerApplication Areas

Industries

Need more details? Our contact person will be happy to assist you

Resources

Brochures for download

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH