Sampler from Zeppelin Systems

Safe Sampling for the Highest Product Quality

Spot Sampling or Continuous Analysis – Zeppelin Systems Provides the Right Sampler for Every Application

When it comes to securing the production process and evaluating the quality of the final product, representative samples of the bulk material must be taken. Sampler from Zeppelin Systems provide safe sampling of flowable powdered or granular bulk materials from silos, containers, downpipes, or pneumatic conveying systems. The sample can be taken under normal atmospheric conditions or in a pressure range up to 1 bar(g).

Zeppelin Systems offers two differently operating samplers that differ in how the sample is taken: either the bulk materials are extracted discontinuously/batch-wise from a container or downpipe, or the sampling is continuous. Both samplers are available in different sizes and can also be used at higher temperatures and pressures.

Your Main Advantages at a Glance

- High Purity: All surfaces that come into contact with the bulk material are made of stainless steel

- Flexible Installation Position: The sample can be taken from a stationary or moving column of bulk material. With the GC type sampler, a sample can even be taken from a pneumatic conveying system in a pipeline.

- Long Service Life, Extended Maintenance Intervals, and Low Repair Costs: Unique and durable sealing systems ensure a long operational lifespan.

- Standardized products with a short delivery time.

Our Certifications

The Sampler Types from Zeppelin Systems

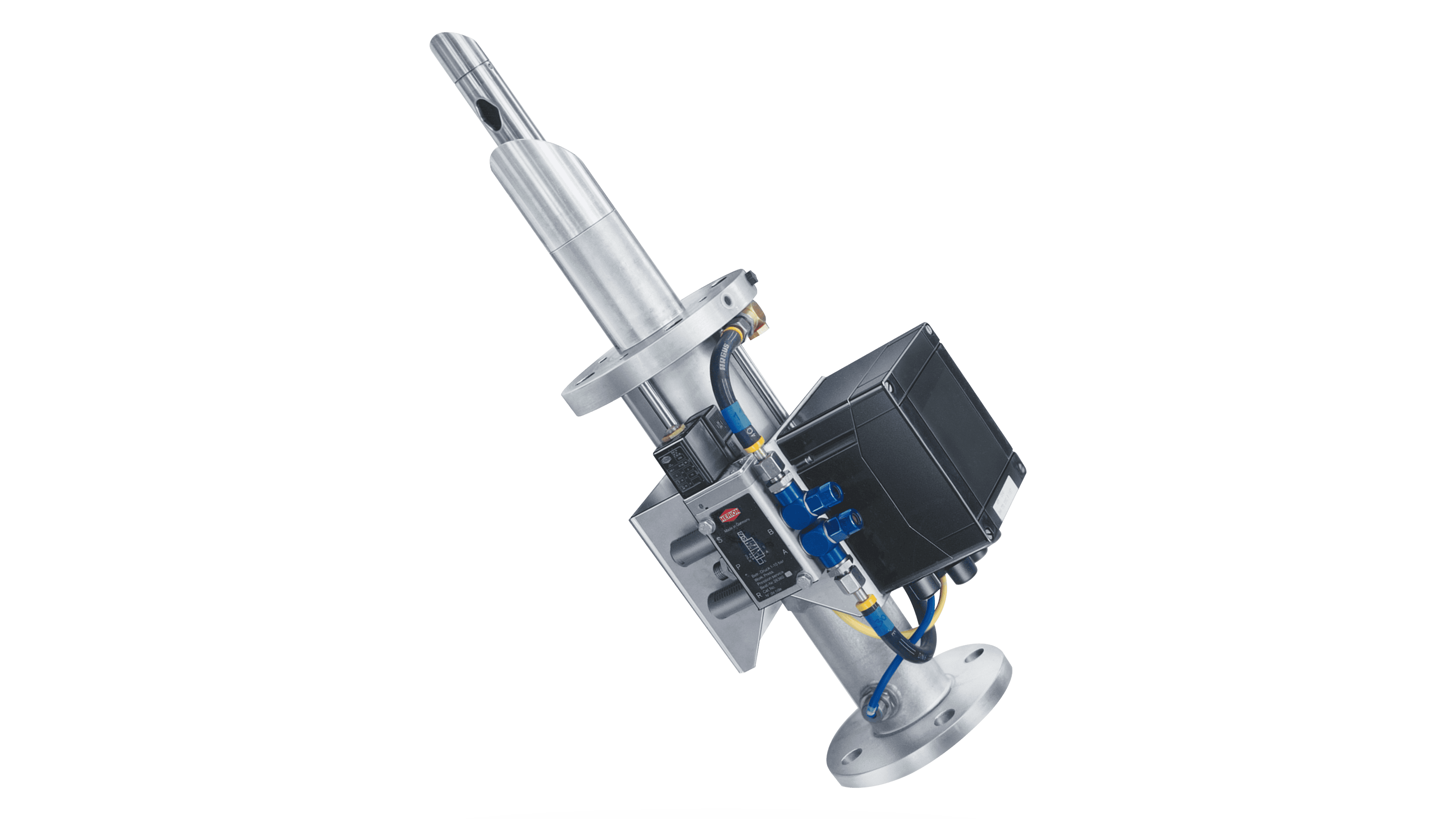

Granucheck Sampler GC

The GC sampler is primarily used for sampling free-flowing, granular bulk materials and coarse powders, under normal atmospheric conditions or in a pressure range up to a maximum of 1.0 bar(g).

Depending on the need, it can be set to continuous or batch operation by extending and retracting a sampling probe. This allows the desired sample quantity to be freely selected over the sampling period.

Motan Sampler MPN

The MPN sample taker is used for sampling free-flowing, fine-grained, non-cohesive powders, coarse powders, and free-flowing standard granules from the bulk material flow, containers, and downpipes under normal atmospheric conditions or in a pressure range up to 1.0 bar(g).

A defined sample quantity is taken per switching cycle, depending on the size and piston volume. The sample amount can be controlled by the number of strokes and can be individually set using a time control.

Application Areas

Sample Takers in Use Across Various Industries

Need more details? Our contact person will be happy to assist you

Our samplers are used in various industries

The samplers can also be used in other industries besides those listed below. Please feel free to contact us to discuss whether our samplers can be used for your application – We Create Solutions!

Plastics

Zeppelin Systems samplers can be used to collect a wide range of plastic powders and granulates, making the samples available for further evaluation and analysis. These are usually polyolefins, compounds, and technical plastics. Either the free-flowing bulk material is filled into sample containers (GC, MPN) in portions after the samplers, or the bulk material is pneumatically conveyed over a longer distance in a conveyor line to a receiving container (e.g., laboratory) by the conveyor pressure (GC).

Chemicals

In this industry, the handling of powders predominates, often including abrasive bulk materials that can range from easy to difficult to flow. Our samplers are also suitable for free-flowing, powdery bulk materials and granulates.

Rubbers & Tires

The raw materials used in tire production are usually carbon black and silica, with other additives as required. The MPN sampler is often used for beaded tire carbon black or compacted silica, as it allows the increase in fine particles (powder content) to be determined at various positions throughout the entire processing process.

Related Products

Other Products from the Process Step

Go to Conveying

Rotary feeders

The right rotary feeder for your application

Dosing, feeding, discharging – Rotary feeders from Zeppelin Systems keep bulk materials in motion. They ensure safe feeding into pneumatic conveying systems, relieve subsequent components under silos, and take on dosing tasks.

Go to rotary feeders

Valves

Set the Direction!

Our diverters are designed for long-lasting durability and are exceptionally reliable. The range extends from cost-effective standard solutions to custom-made options – in any case, we know the right direction. Various designs, surface finishes, materials, and seals are available to meet your specific needs.

Go to valves

Dosing & Conveying screws

We've Got It Down!

The dosing and conveying screws from Zeppelin Systems dose and transport bulk materials of all kinds. Additionally, they are also suitable for precise scale filling. The screws can be optimally adapted to the specific application. For example, a hygienic version with quick cleaning is available for baby food production, as well as dust-tight versions for handling powders.

Go to dosing & conveying screwsOur Customer Services for You at a Glance

Show all Customer ServicesRessources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH