Small Component Weighing

Solutions for small component dosing

Customised dosing systems for every industry

The right small component dosing for every challenge

Zeppelin Systems offers a comprehensive range of small component dosing systems specially designed for the precise and efficient handling of bulk ingredients in various industries. These systems are designed to store, dose and accurately weigh both free-flowing and difficult-to-flow bulk materials. They are used in the food, chemical and pharmaceutical industries and are ideal for the production of mixtures that require maximum accuracy and flexibility.

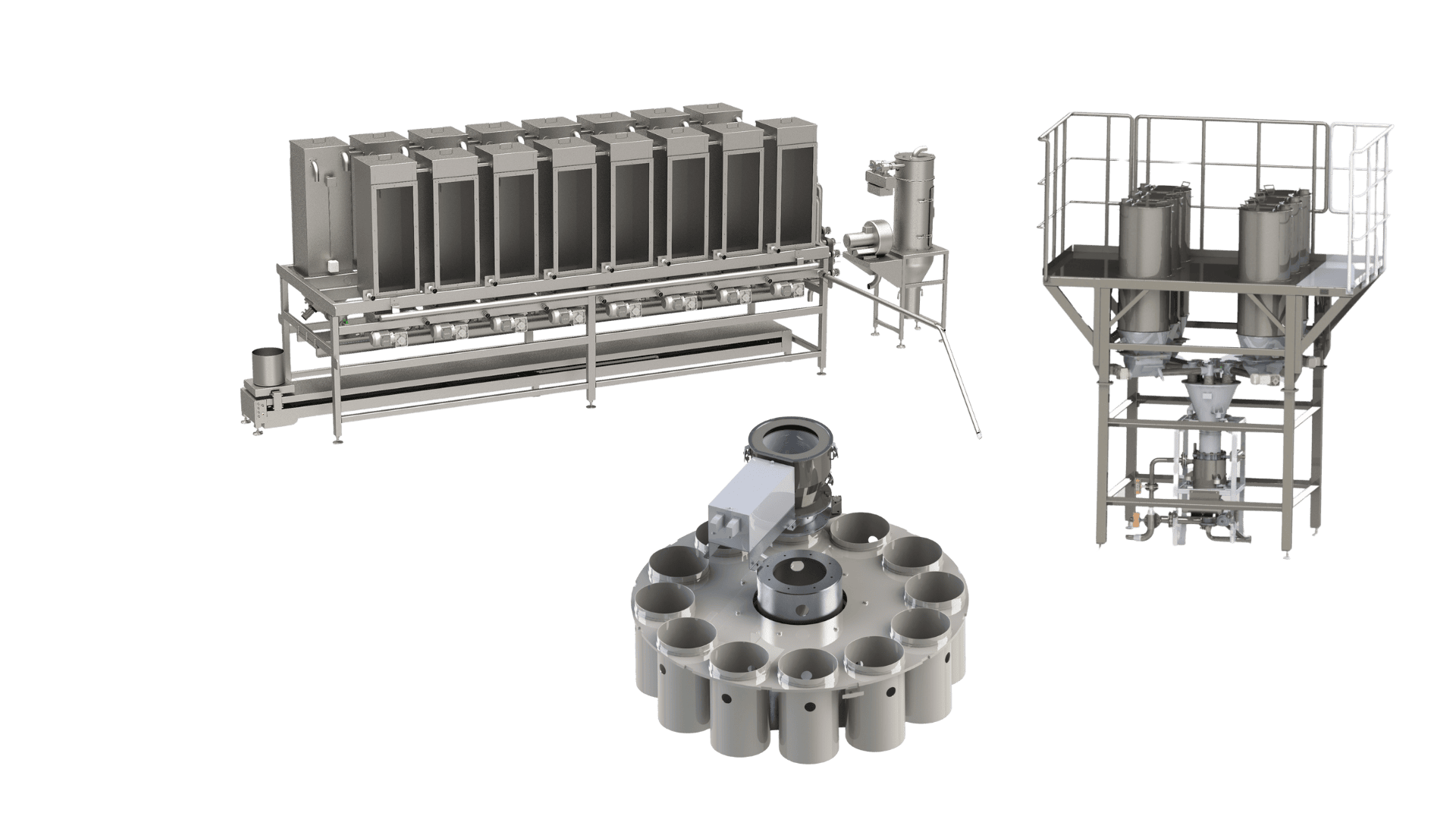

Our solutions for weighing small components at a glance

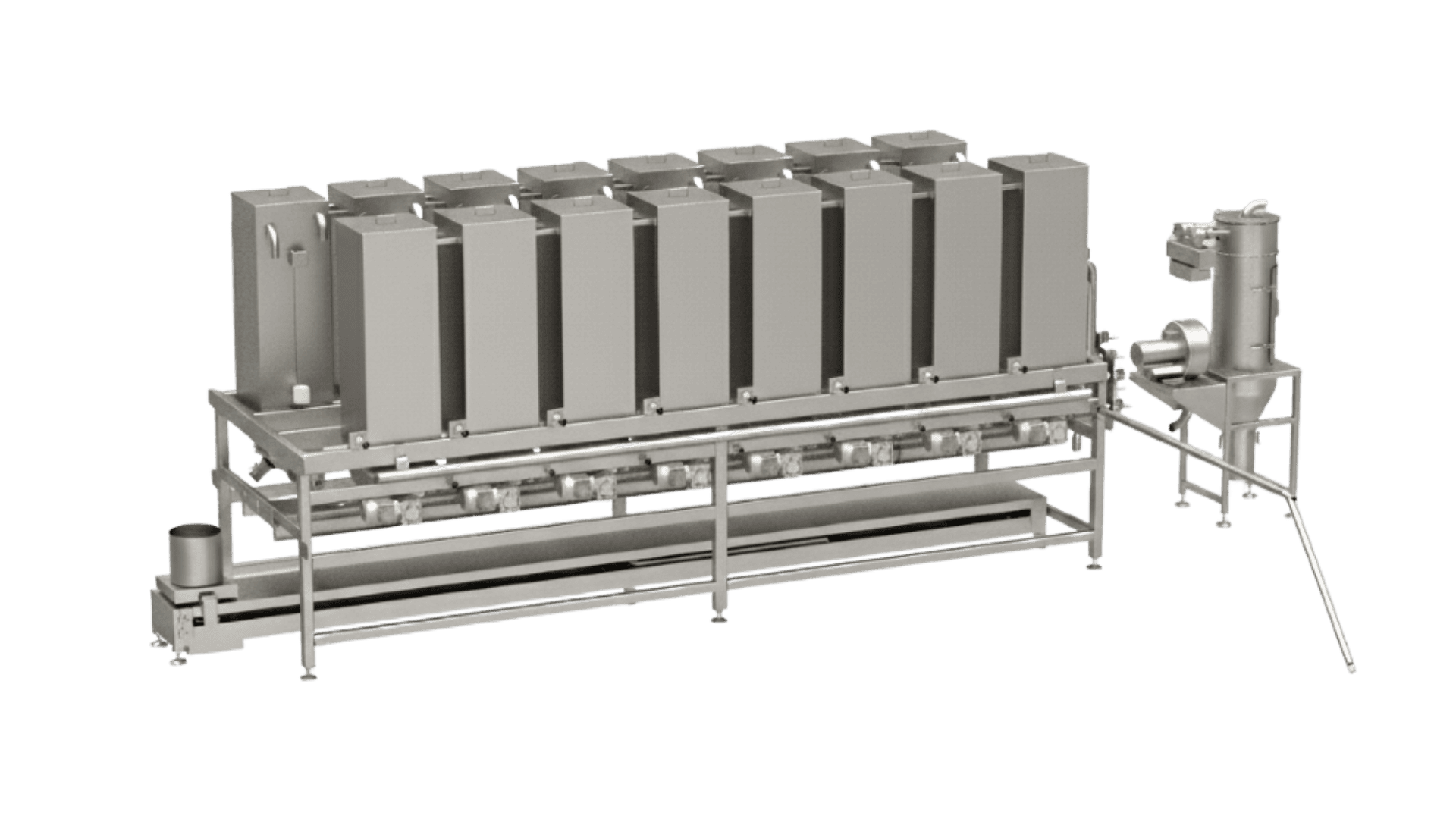

MinDos small component weighing

The MinDos (Minor Ingredients Dosing System) small component dosing system is mainly used in the food industry, where the trend is towards industrial-scale ingredient systems integrated into fully automated large-scale plants.

Zu Mindos

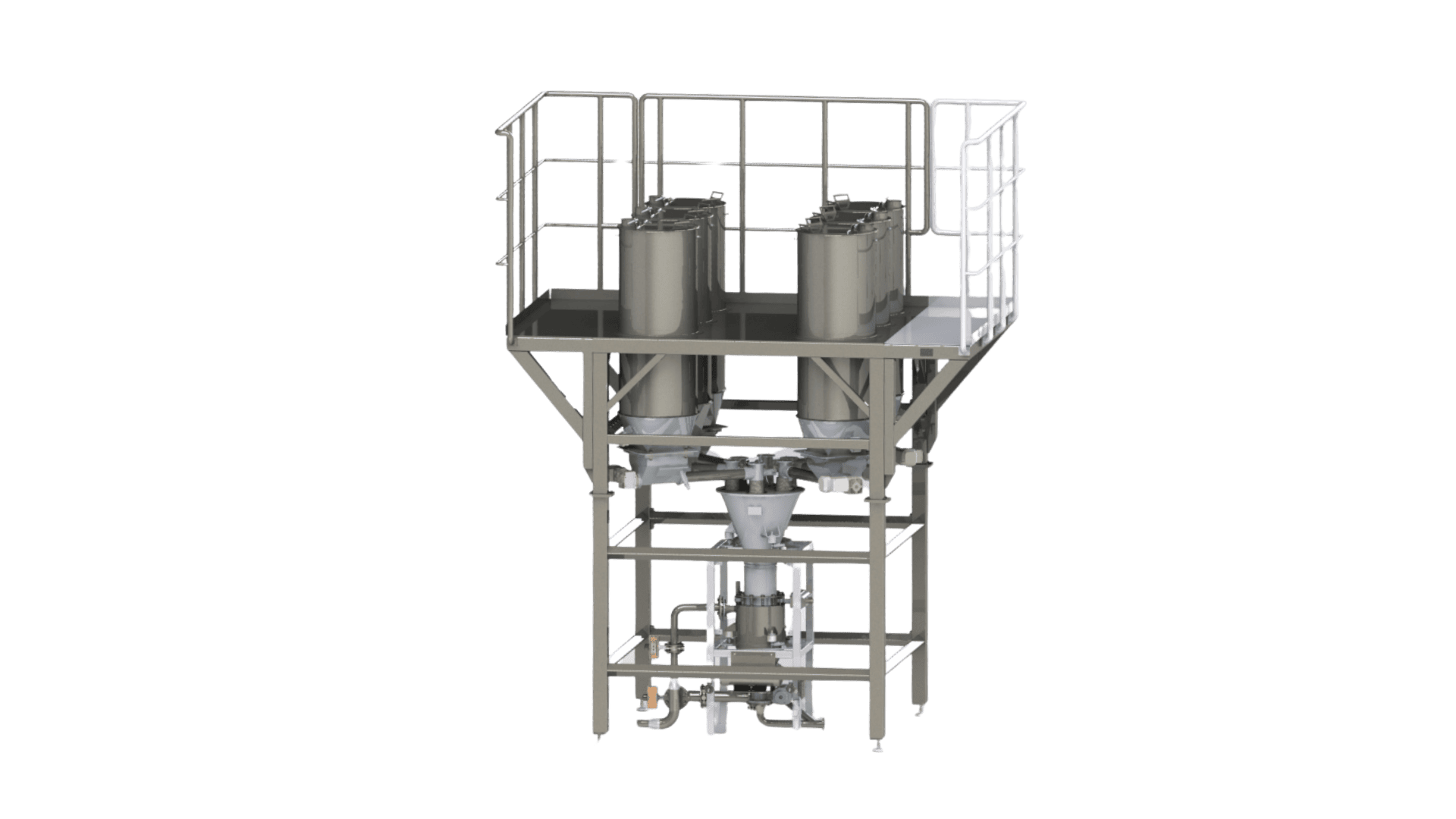

MacDos small component weighing

The MacDos system (Macro Ingredients Dosing System) automates the handling of bulk ingredients in the food, chemical, and pharmaceutical industries. It is ideal for storing, sequentially dosing, and precisely weighing up to eight free-flowing to heavy-flowing bulk materials.

To Macdos

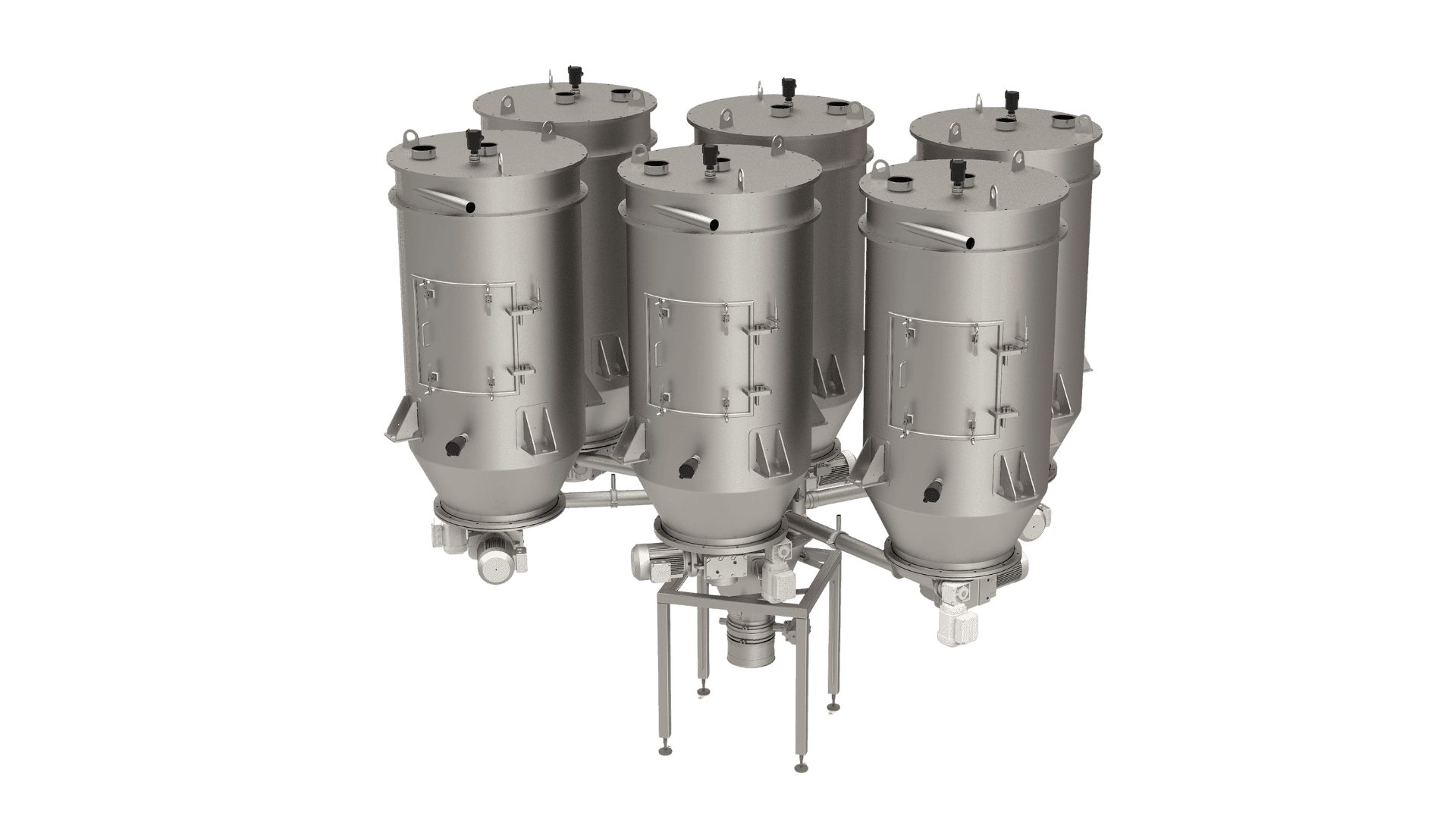

MicDos small component weighing

The MicDos (Micro Ingredients Dosing System) small component dosing system automates the handling of bulk ingredients in the food, chemical, and pharmaceutical industries. The system is suitable for storing, sequentially dosing, and accurately weighing up to 20 free-flowing to heavy-flowing bulk materials.

To Micdos

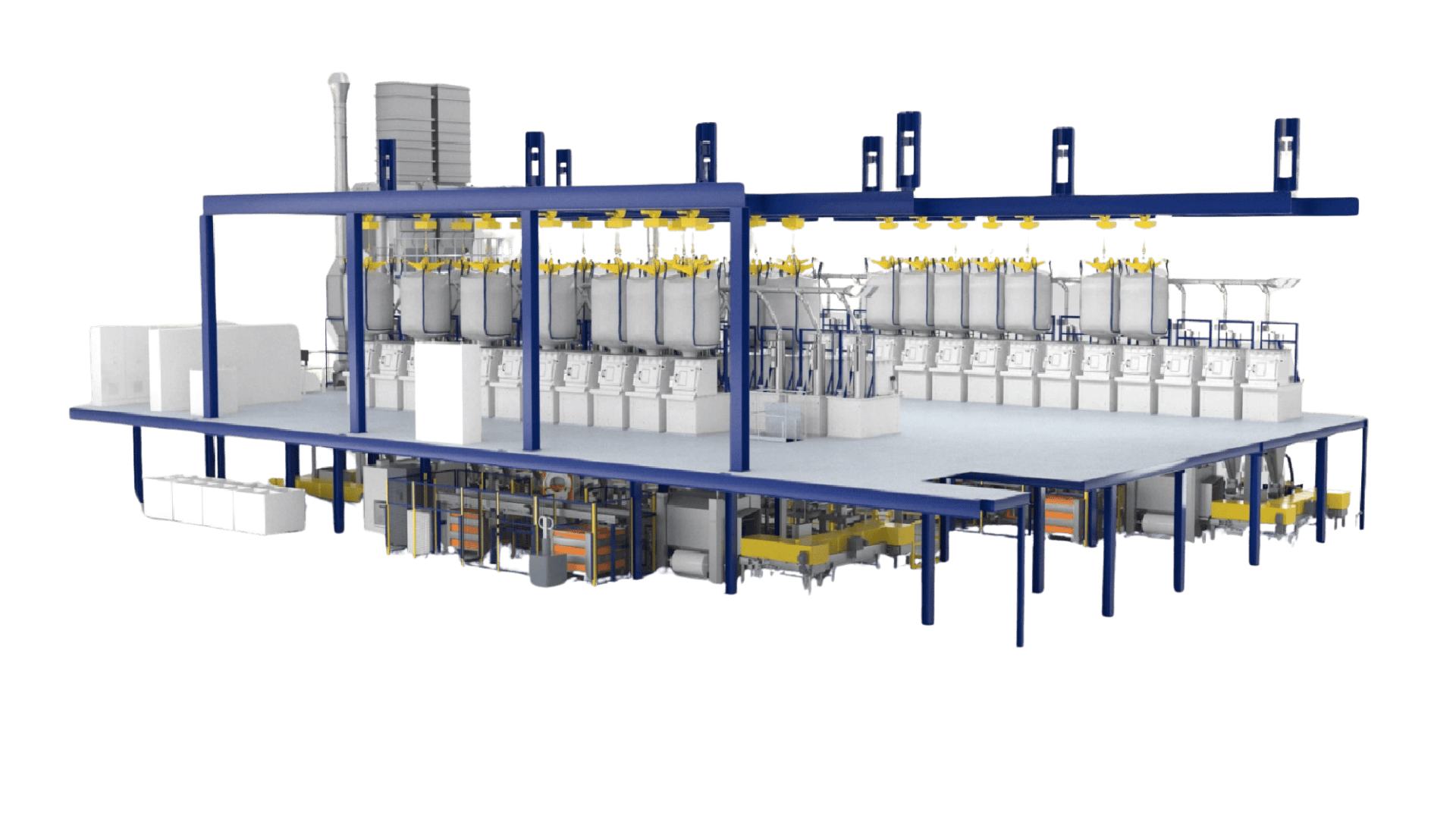

ASCW Automatic Small Components Weighing System

The ASCW (Automatic Small Components Weighing System) automatically doses and weighs granular or powdered bulk materials with different bulk densities and flow properties. The system also prepares bulk material batches that are required in particular for the production of rubber compounds.

Zum ASCW

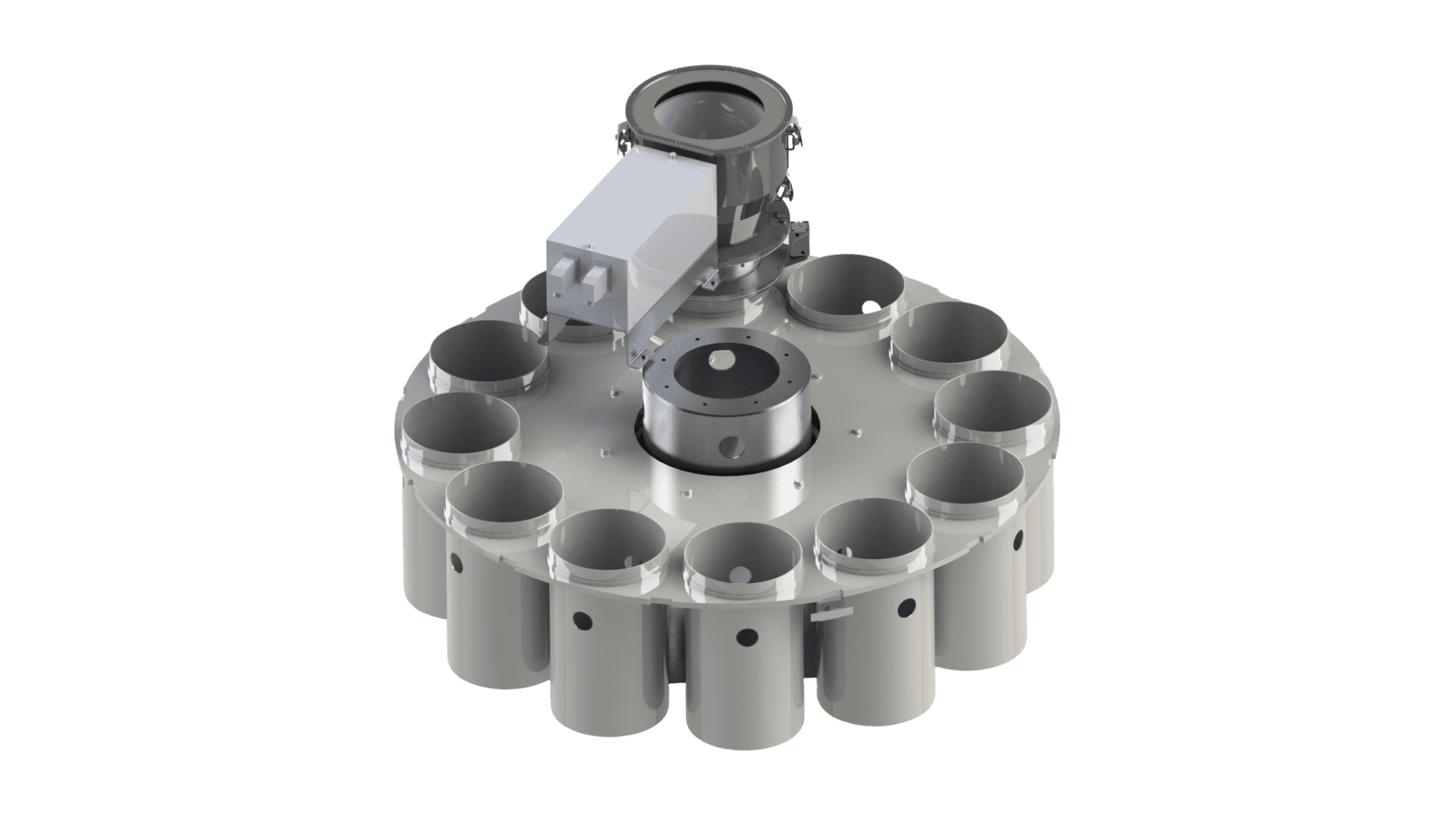

Carousel small component weighing CSCW

The semi-automatic small component weighing system CSCW (Carousel Small Components Weighing) is used for the manual weighing of granular or powdered bulk materials with different bulk densities and flow properties. It is also used for the provision of bulk material batches, in particular for the production of rubber compounds.

Zum CSCW

Dosing & Conveying screws

For mechanical conveying over short distances, as well as for discharging and dosing powdered and granular bulk materials, our screw conveyors have proven themselves in numerous applications. They are characterized by a robust construction, easy cleanability, and high dosing accuracy. Our pipe or trough screw conveyors can be flexibly adapted to your requirements and products.

Go to dosing & conveying screws

Conveying, Dosing, and Mixing System DMG

The conveying, dosing, and mixing system DMG is primarily used for processing granulates and granular ground materials in multi-component mixtures in the rubber, plastics, and chemical industries.

Go to Conveying, Dosing, and Mixing SystemApplication Areas

Industries

Plastics

We design each Zeppelin system for plastic processing according to your specific customer requirements. You benefit from our decades of experience and our own innovative processes and technologies developed for the industry.

Go to plastics industry

Rubber & Tire

As recognized process experts, we know every step of the rubber and tire industry in detail. Our well-thought-out solutions provide you with measurable advantages across the entire value chain, including the recycling of end-of-life tires.

Go to rubber & tire industry

Chemistry

There are countless recipes and concepts for the production, processing, and recycling of plastics. With us by your side, you ensure that they always become successful recipes and concepts. We offer the full range of plastic plants, from process, mixing, and storage silos to conveyor systems, key components, and cleaning systems. What sets our plants apart: full flexibility, decades of expertise, patented process solutions, and a globally networked industry specialist.

Go to chemistry

Food

No other company has such extensive experience in building modern plants for food technology. The foundation for our success? We make no compromises. It's not just the bakery and confectionery industry that values our comprehensive expertise in raw material handling: from raw material intake and storage to discharge, conveying, processing, dosing, and mixing and control.

Go to food industryWould you like more details? Our contact persons will be happy to assist you.

Ingo Pütz

Global Market Manager Sales Food Processing Plants

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH