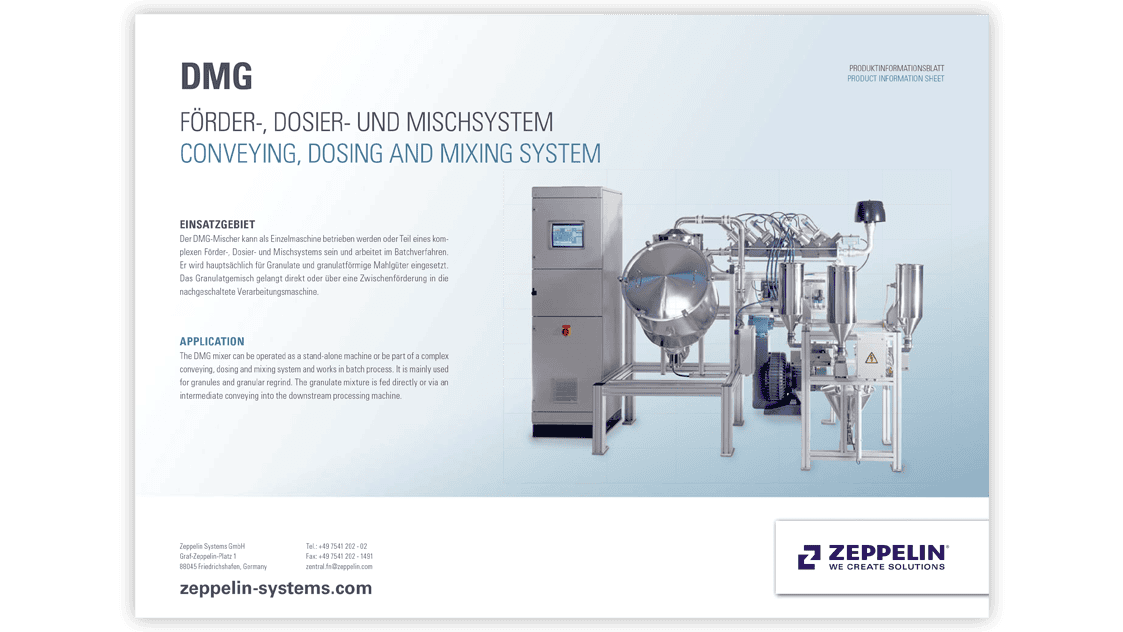

DMG Conveying, Dosing, and Mixing System

For Combining, Dosing, and Mixing Granules

Precision through Gravimetrics

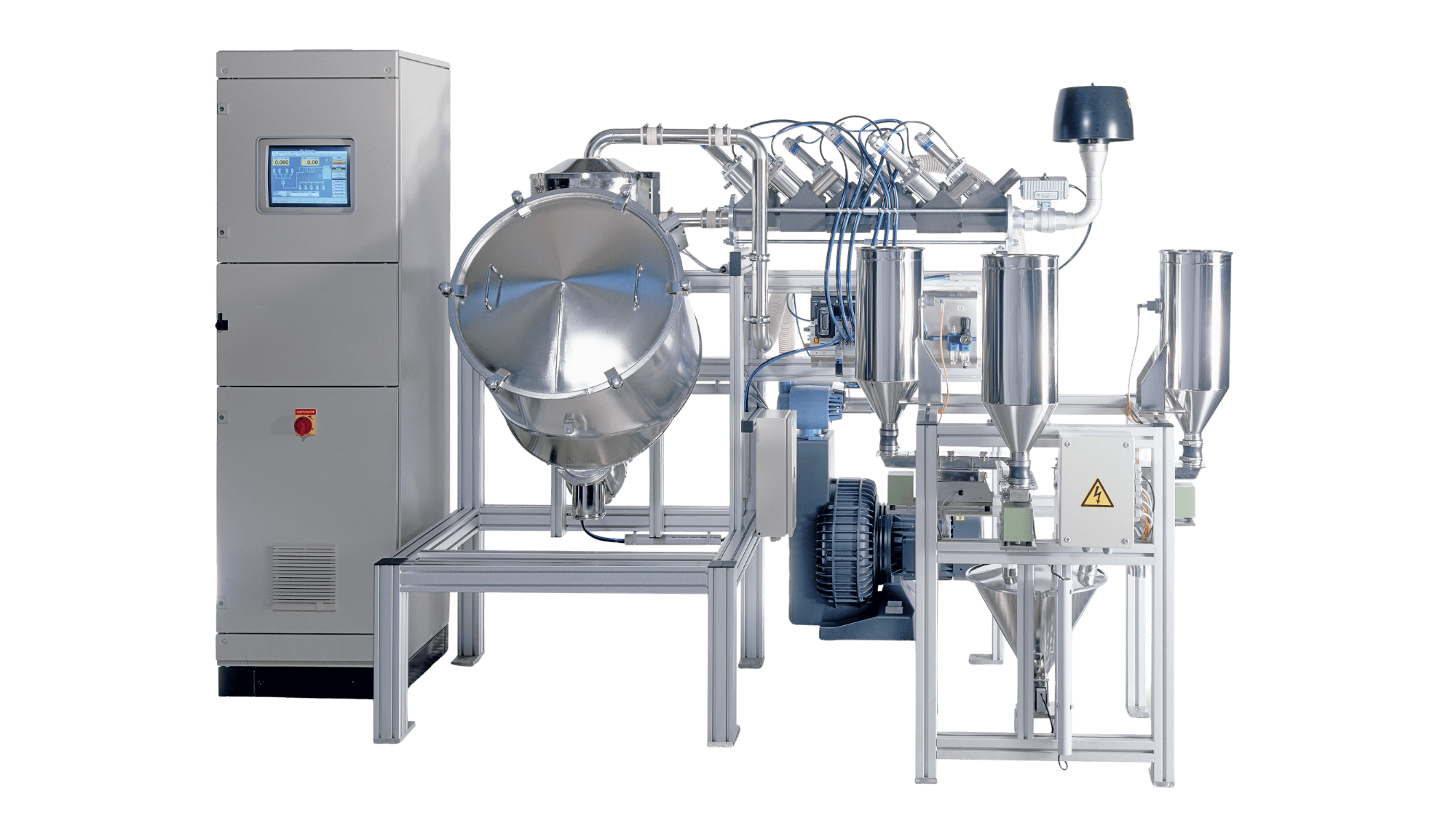

The DMG conveying, dosing, and mixing system is primarily used for processing granulates and granular ground materials in multi-component mixtures within the rubber, plastics, and chemical industries. It operates gravimetrically in batch mode and can function as a standalone machine or as part of a complex conveying, dosing, and mixing system. It processes up to ten main components and four (or six) minor components, including plastic granulates such as virgin material, regrind, recyclate, or additives. The granulate mixture is fed directly or via intermediate conveying to the downstream processing machine after the mixing process.

Key Advantages at a Glance:

- Fully Automated Dosing System

- Modular and Compact System

- High Dosing and Weighing Accuracy thanks to separate weighing systems

- Time-Saving due to fast installation, commissioning, cleaning, and maintenance

- Gentle Mixing Process

- Low Temperature Input

- Self-Optimizing Dosing with post-run correction and freely selectable tolerance control

- Reproducible and Documentable Product Compositions through protocols and evaluations

- High Reliability as product-contacting parts are corrosion-resistant

Benefits

Mixing and Dosing – Powerfully Combined

Dosing Performance

Performance

Throughput

Our Advantages for the Industry

Chemistry & Plastics

For the production and compounding of technical plastics, PTA/PET, as well as battery pastes, specialty chemicals, and paints, Zeppelin Systems offers customized plant concepts, even for challenging raw materials and materials. Our systems impress with:

- High Performance and Dosing Accuracy

- Process & Operational Safety

- Flexible Applicability

- Modular System

Rubber & Tire

In the rubber and tire industry, the highest accuracy is required at every processing step. This is even more complex due to the significant differences in the properties of raw materials. Solutions from Zeppelin Systems meet this challenge and not only adhere to the highest standards in environmental and health protection but also impress with maximum productivity through:

- High Performance and Dosing Accuracy

- Process & Operational Safety

- Flexible Applicability

- Modular System

Need more details? Our contact person will be happy to assist you

Related Products

Complementary Products for an Optimized Process Chain

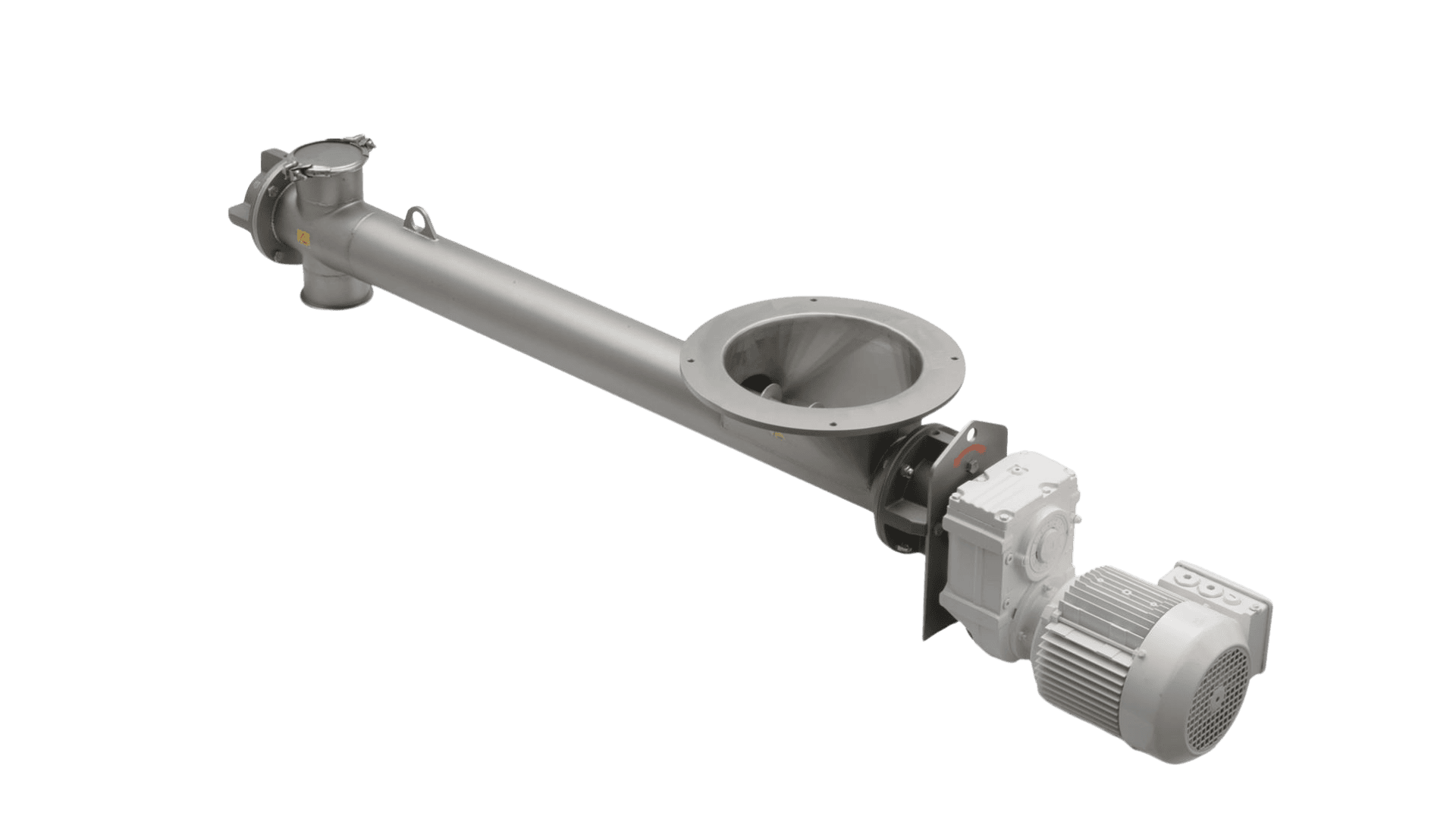

Dosing and Conveying Screws

When it comes to the smooth dosing of dry, powdery, and granular bulk materials, our dosing and conveying screws come into play.

Go to Dosing & Conveying Screws

KOKEISL Discharge and Dosing Module

Reliable discharge and precise dosing become effortless with the mechanical discharge and dosing module KOKEISL. A wide variety of bulk materials can be transferred in any quantity with extremely high throughput accuracy from silos and containers into other vessels.

Go to Discharge ModulesOur Customer Services for You at a Glance

Show all Customer ServicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH