Liquid Weighing System LWS

The Liquid Weighing System for Simple Applications

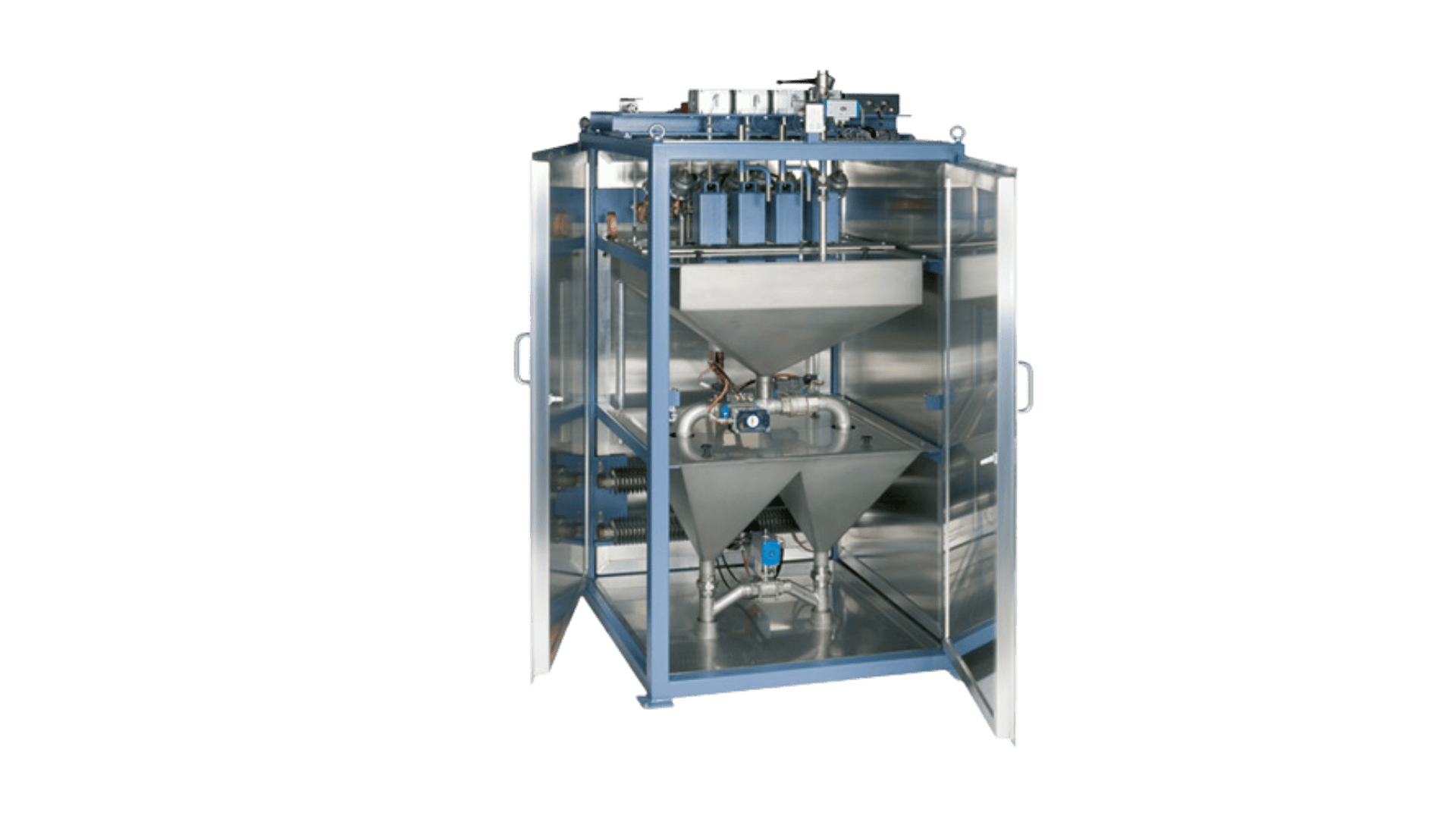

The varying flow characteristics of the media are compensated through heating of the weighing unit as well as by adjusting the opening degree of the dosing valves. The system provides high weighing accuracy using separate angle-seat piston valves with stroke limitation for coarse and fine flow. After weighing, the liquids are discharged into an intermediate tank and then injected into the desired process via a pump.

The integrated level monitoring and the safety level switch in the drip tray ensure maximum operational safety by preventing overfilling and oil leakage. This system is flexible and service-friendly, featuring easy installation and good accessibility for maintenance and cleaning.

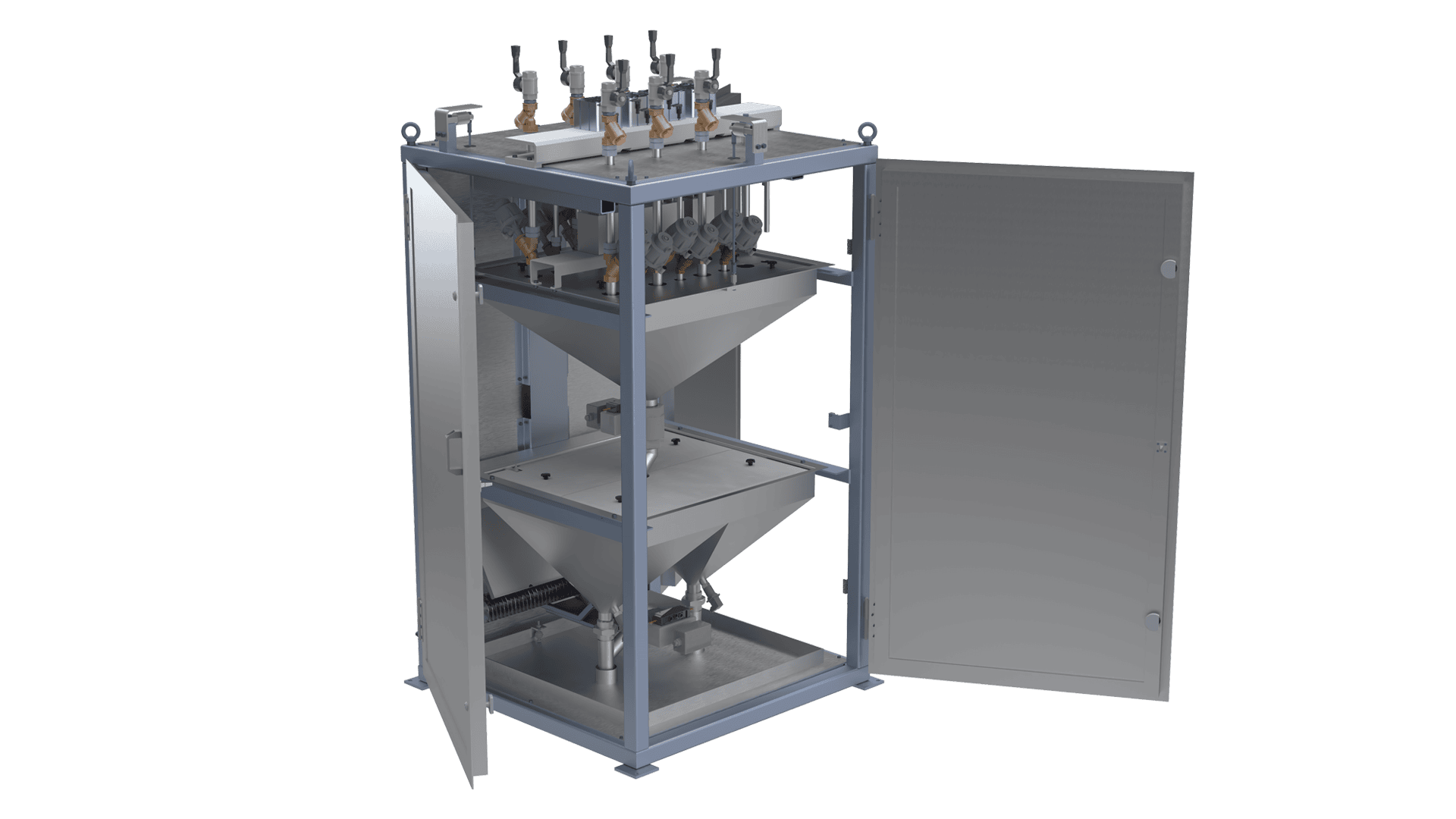

Automatic Weighing System for Process Oils with Highest Precision

High Dosing and Weighing Accuracy

Equipped with separate valves for coarse and fine dosing, as well as media temperature control and thermal insulation to ensure optimal viscosity management.

High Process and Operational Safety

Robust and durable design with optional modular taring unit with automatic taring function.

Flexibility

Additional weighing hopper and intermediate tank increase system availability and maximize batch throughput.

Safety

Level monitoring of weighing hopper and intermediate tank, drip tray level switch, strainer in the liquid inlet, temperature monitoring and control.

Servicefreundlich

Easy installation and commissioning, excellent accessibility for maintenance and cleaning through doors on three sides, smooth surfaces for easy cleaning, and a low number of wear parts.

Fully Automatic Liquid Weighing System for Precise Dosing of Process Oils

The Liquid Weighing System (LWS) is available in several configurations, for example with one or two weighing hoppers or with an intermediate tank in closed design. Electric heating of the interior up to 70°C can be integrated. The system can accommodate up to eight coarse and fine dosing valves (DN25 / DN15). It also features insulated outer surfaces and access doors, as well as a control cabinet equipped with electrical and pneumatic switching components. System operation is controlled via PLC.

Options:

- Configurations with two weighing hoppers and/or intermediate tanks for connection of up to 10 coarse and 16 fine dosing valves

- Modular taring unit with reference weights – automatic taring function at adjustable intervals for very high process and operational reliability

- Interior heating with water or steam

- Custom sizes available upon request

Key facts at a glance

Sizes

Weighing hoppers: 80 / 120 L (2 × 40 L), Intermediate tanks: 80 / 120 L (2 × 40 / 60 L)

Application Area

For automatic dosing and weighing of up to eight process oils and plasticizers in one or two weighing hoppers. Internal transfer of liquids into one or two intermediate tanks, followed by delivery to one or two pumps for injection into powder mixers in the plastics and rubber industry.

Pressure Range

Atmospheric (non-pressurized)

Temperature Range

Ambient: 0°C to +45°C, Media: +5°C to +75°C

Materials

All liquid-contacting surfaces of hopper, tanks and piping made of stainless steel; hopper surfaces pickled and passivated.

Engine

One or two injection pumps

Precision Weighing System for Liquids in the Plastics and Rubber Industry

The LWS Liquid Weighing System is primarily used for batch-wise weighing of non-flammable liquids and process oils for feeding powder mixers in the plastics and rubber industry:

- Batch dosing of liquids

- Batch weighing of non-flammable liquids and process oils (e.g., plasticizers)

- Feeding of powder mixers in the plastics and rubber industry

Advantages for the industry

Plastics

When it comes to introducing difficult-to-process raw materials and substances into the production process in a gentle, precise, and timely manner, in the correct sequence and with exact dosing, Zeppelin’s solutions for the production and compounding of engineering plastics, PTA/PET, battery materials, specialty chemicals, and paints are the right choice. We not only offer tailored plant concepts but also have the expertise to develop optimal solutions.

Go to plastics industry

Chemistry

There are countless recipes and concepts for the production, processing, and recycling of plastics. With us by your side, you ensure that they always become successful recipes and concepts. We offer the full range of plastic plants, from process, mixing, and storage silos to conveyor systems, key components, and cleaning systems. What sets our plants apart: full flexibility, decades of expertise, patented process solutions, and a globally networked industry specialist.

Go to chemistry

Rubber & Tire

Worldwide, we have already completed over 500 projects for the rubber and tire industry – from individual silos to fully turnkey plants. Our well-designed solutions provide measurable advantages across the entire value chain, all the way to recycling. We consistently focus on excellence in terms of material selection, technology, durability, and service.

Go to rubber & tire industryWant more details? Our contact persons will be happy to help you.

Our Customer Services for You at a Glance

Show all Customer ServicesRessourcen

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH