Processing

Specific mixing solutions

Greater efficiency in the mixing process

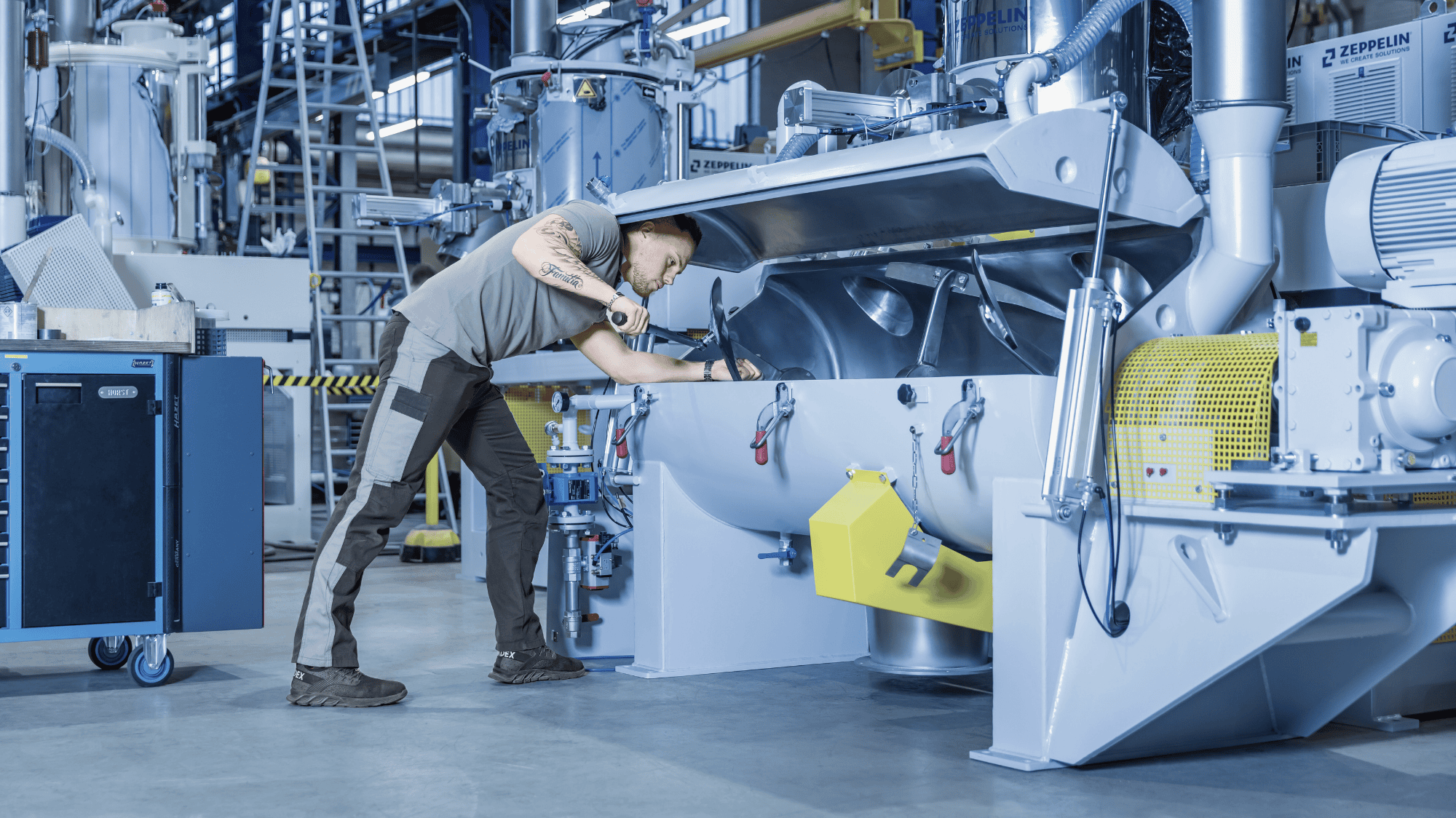

Every product—whether paints, battery slurries, or pasta dough—has its own specific mixing requirements. And yet, some needs are universal: short mixing times, high efficiency, and perfectly homogenized results. Zeppelin Systems develops tailor-made solutions for every industry.

Maximum throughput, exceptional reliability, and long service life.

When it comes to mixing, the focus is not only on achieving the perfect blend, but also on using only as much energy as necessary while treating the product as gently as possible. Our mixing solutions stand out through:

- Excellent mixing quality

- Industry-specific solutions

- Efficient mixing tools

- Gentle processing

- Energy-saving temperature control solutions

Mixing Silos

In the production or recycling of plastics, consistently achieving high product quality can be challenging due to process or raw material fluctuations. This is where our mixing silos make all the difference. The gravity mixers from Zeppelin Systems handle even large product volumes with minimal recirculation, producing an exceptionally homogeneous mix without any additional energy input. The result: a high-quality end product.

Go to mixing silos

Kneader

How can large quantities of dough be mixed and kneaded efficiently? And how can liquids and solids be continuously dosed and homogenized? One answer is the Codos® NT, which ensures optimal dough quality. The DymoMix complements this by wetting powdered components with water or oil and injecting air, creating a homogeneous mixture extremely quickly and without dust. Both processes are the result of decades of expertise and innovation-driven thinking. The outcome: flavorful, high-quality baked goods as well as pasta and waffle doughs.

Go to kneaderApplication Areas

Industries

Food

No other company has as much experience in building modern systems for the food industry as Zeppelin Systems. Every step in raw material handling – from intake and storage to conveying, conditioning, dosing, and perfect mixing – has been refined over many years. The result: seamlessly integrated systems from a single source.

Go to food industry

Rubber & Tire

As proven process experts, we know every detail of the workflows in the rubber and tire industry. That’s why our well-engineered solutions deliver measurable benefits across the entire value chain – all the way to the recycling of used tires.

Go to rubber & tire industry

Chemistry

Zeppelin offers customized plant concepts even for hard-to-process raw materials and substances. We ensure that all materials are introduced into the processing sequence gently, in the specified order, with precise timing and dosing – to achieve a perfect end product.

Go to chemistry industry

Plastics

Every Zeppelin system for plastics processing is tailored to your specific requirements. You benefit from our decades of experience and our proprietary, innovative processes and technologies developed specifically for the industry.

Go to plastics industryExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH