Discharge Aids by Zeppelin Systems

Getting Bulk Materials Moving

Efficient Discharge Floors for Smooth Bulk Material Handling

The discharge floors from Zeppelin Systems gently activate poorly flowing bulk materials, preventing blockages in silos and containers. This ensures complete discharge. Various systems can be used flexibly and can also be retrofitted. We support you in selecting the optimal solution with process engineering designs and tests. Our in-house manufacturing allows us to tailor solutions specifically to your application.

Advantages for the Industry

With our discharge and vibrating floors, bulk materials are reliably activated, ensuring silos and containers are safely emptied and subsequent processes run smoothly. These components are versatile and proven across all industries.

Optimal Discharge of Your Bulk Materials

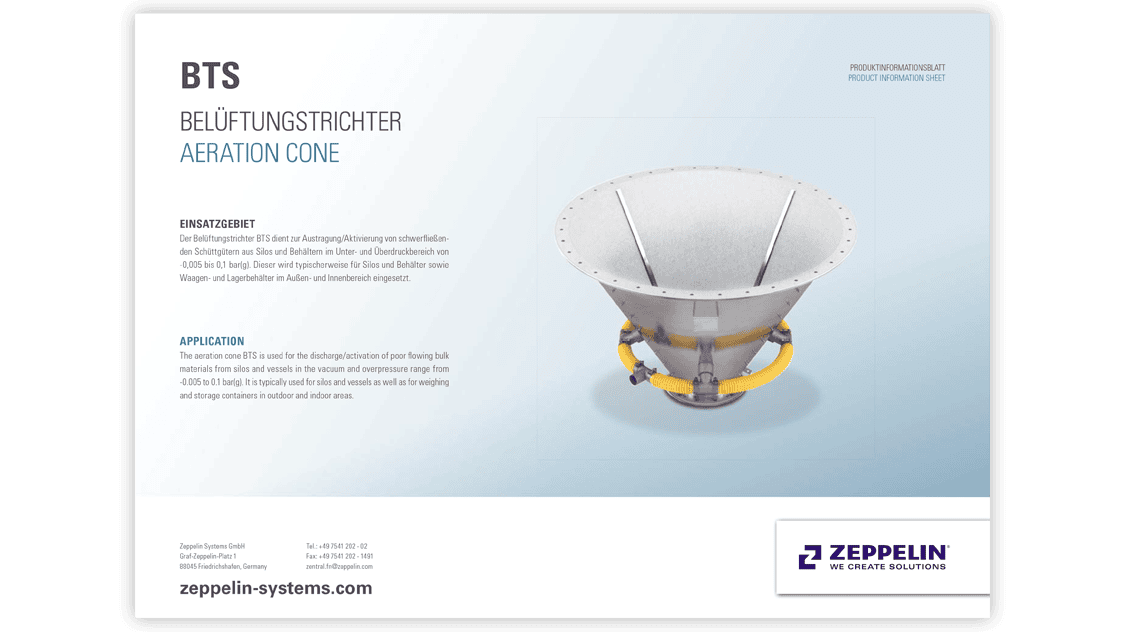

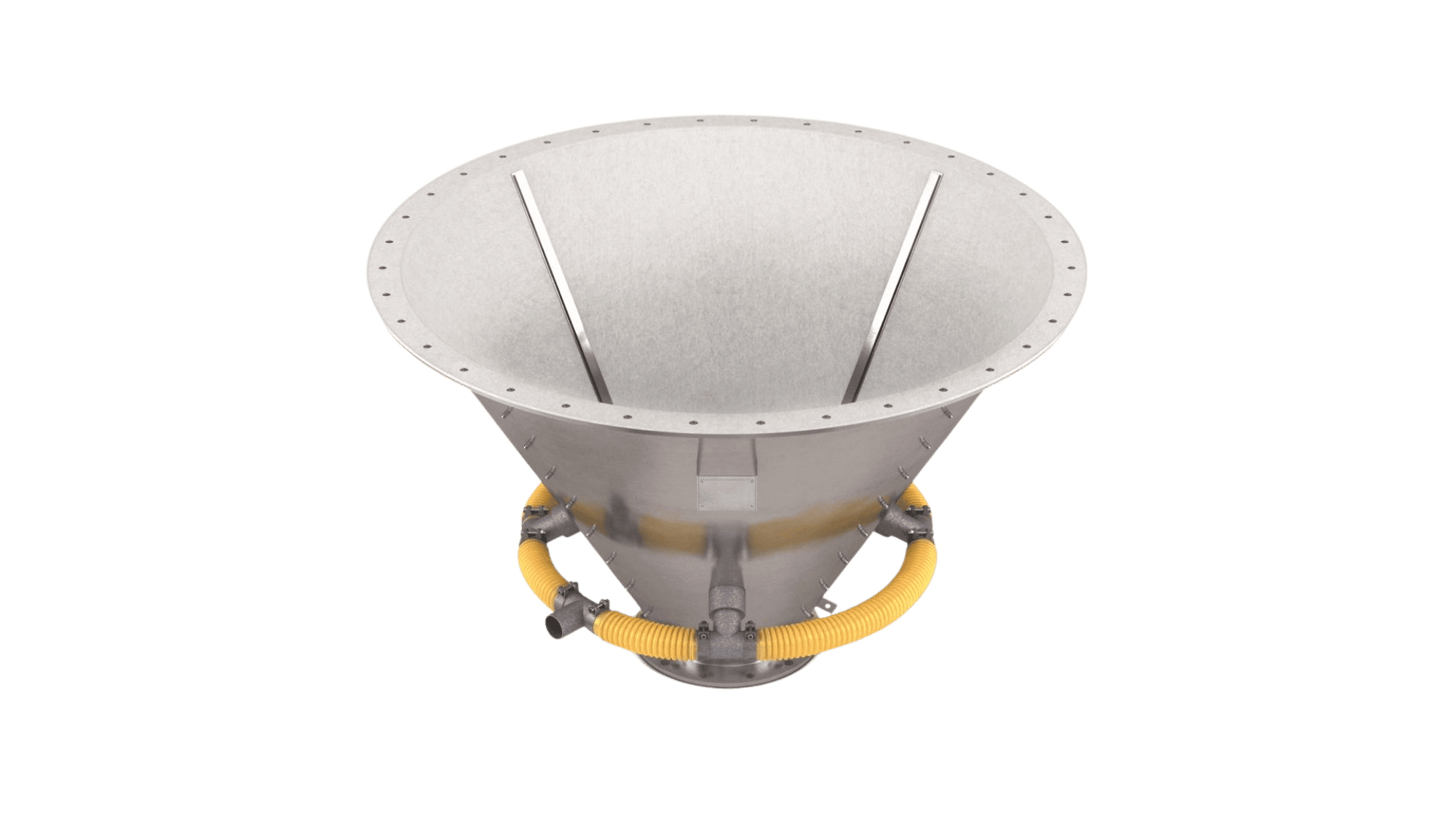

Discharge Floor BTS

The BTS discharge floor with antistatic cloth is suitable for almost all poorly flowing, cohesive bulk materials in the underpressure and overpressure range from -0.005 bar (g) to 0.1 bar (g), ensuring complete discharge from silos. It is typically used for silos and containers, as well as weighing and storage containers in both outdoor and indoor environments. In this system, the bulk material in the discharge area is activated through fluidization and simultaneous mechanical movement. Various cloth materials are available for this purpose, and retrofitting is possible. The BTS discharge floor is characterized by the following features:

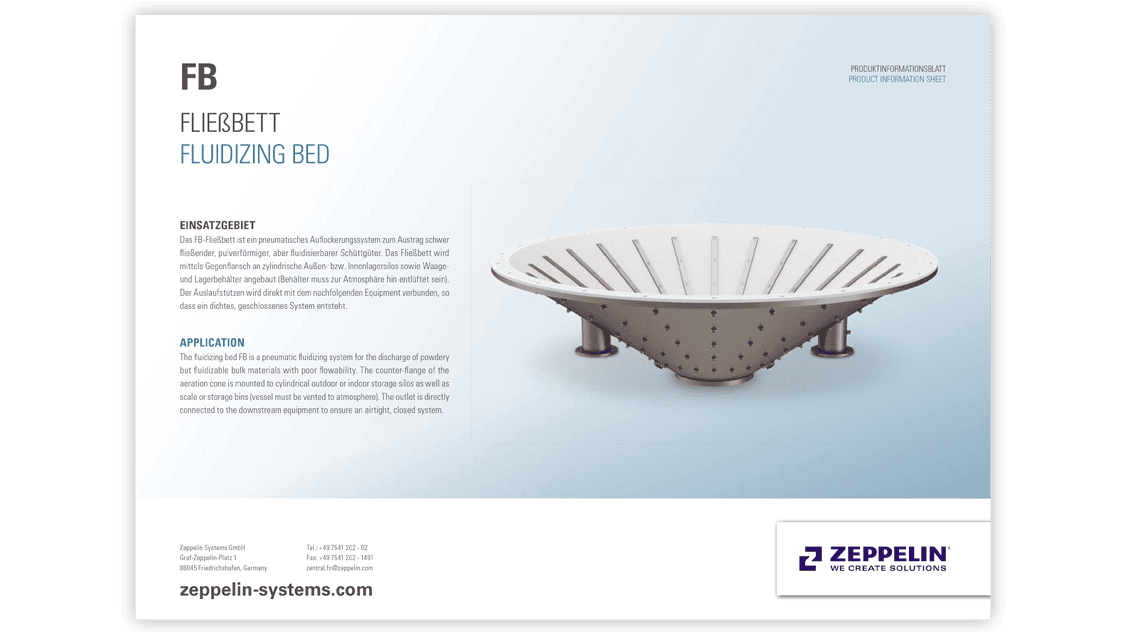

Discharge Floor FB

The FB discharge floor is a pneumatic fluidization system for discharging poorly flowing yet easily fluidizable bulk materials. The fluidized bed is mounted with a drilled counter flange on cylindrical external or internal storage silos, as well as weighing and storage containers. The product discharge is directly connected to subsequent devices such as rotary airlocks, conveyors, chutes, shut-off valves, or other discharge equipment, creating a tight, closed system. Additionally, the fluidized bed offers further applications such as mixing, drying, tempering, and recrystallization. Consult with our experts to receive the best process engineering design for your application. The key features of the FB discharge floor are as follows:

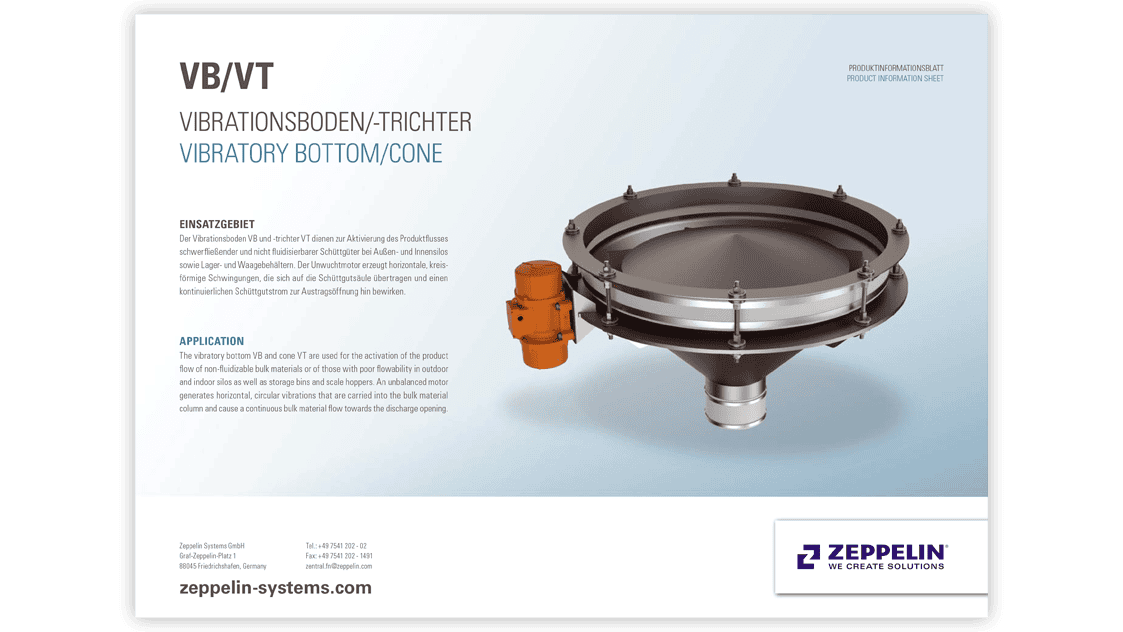

Discharge Floor VB

The VB discharge floor is used to activate the flow of nearly all poorly flowing, non-fluidizable bulk materials for optimal discharge from silos and containers. It is primarily used in outdoor and indoor storage silos, as well as weighing and storage containers. A rotary airlock can be added for dosing the bulk material. The product discharge is connected to the subsequent equipment via a hygienic, non-return C-sleeve and connection stub. This design decouples the vibrating floor both upwards and downwards, creating a tight, closed, free-swinging system. The vibrating floor ensures reliable, bulk-material-friendly, residue-free, and uniform discharge (mass flow) of the bulk material. Additionally, it has the following features:

Application Areas

Industries

The discharge and dosing modules can be used in many other industries. Feel free to contact us to discuss whether our KOKEISL modules are suitable for your application. We Create Solutions!

Food

How can raw materials for the food industry be gently transferred for further processing? With discharge floors from Zeppelin Systems, even sensitive products find their way gently into the process.

Go to food industry

Plastics

The materials used in plastics processing are becoming increasingly complex, for example, when considering fluffy materials such as film scraps in the recycling sector. However, we are able to process even these challenging materials and ensure they are safely transported for further processing.

Go to plastics industry

Rubber & Tire

In modern tire production, high standards are set for accuracy, reliability, and quality. The material flow must not be allowed to stall. Our discharge floors provide you with reliable support in this regard.

Go to rubber & tire industry

Chemistry

Things can sometimes get tough in the chemical industry. We make sure that you are on the safe side with our discharge floors. You benefit from our decades of experience, especially with regard to wear protection and explosion protection requirements.

Go to chemistry industryNeed more details? Our contact person will be happy to assist you

You Might Also Be Interested In

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH