Bin Vent Filters

Efficient bin vent filters from Zeppelin Systems

Safely limit dust emissions

Bin vent filters are used for dust extraction on silos and containers, playing a key role in maintaining air quality. Zeppelin Systems offers both BVD and BVT filters for food applications, as well as BVV filters for the chemical and polyolefin industries.

The different bin vent filters at a glance

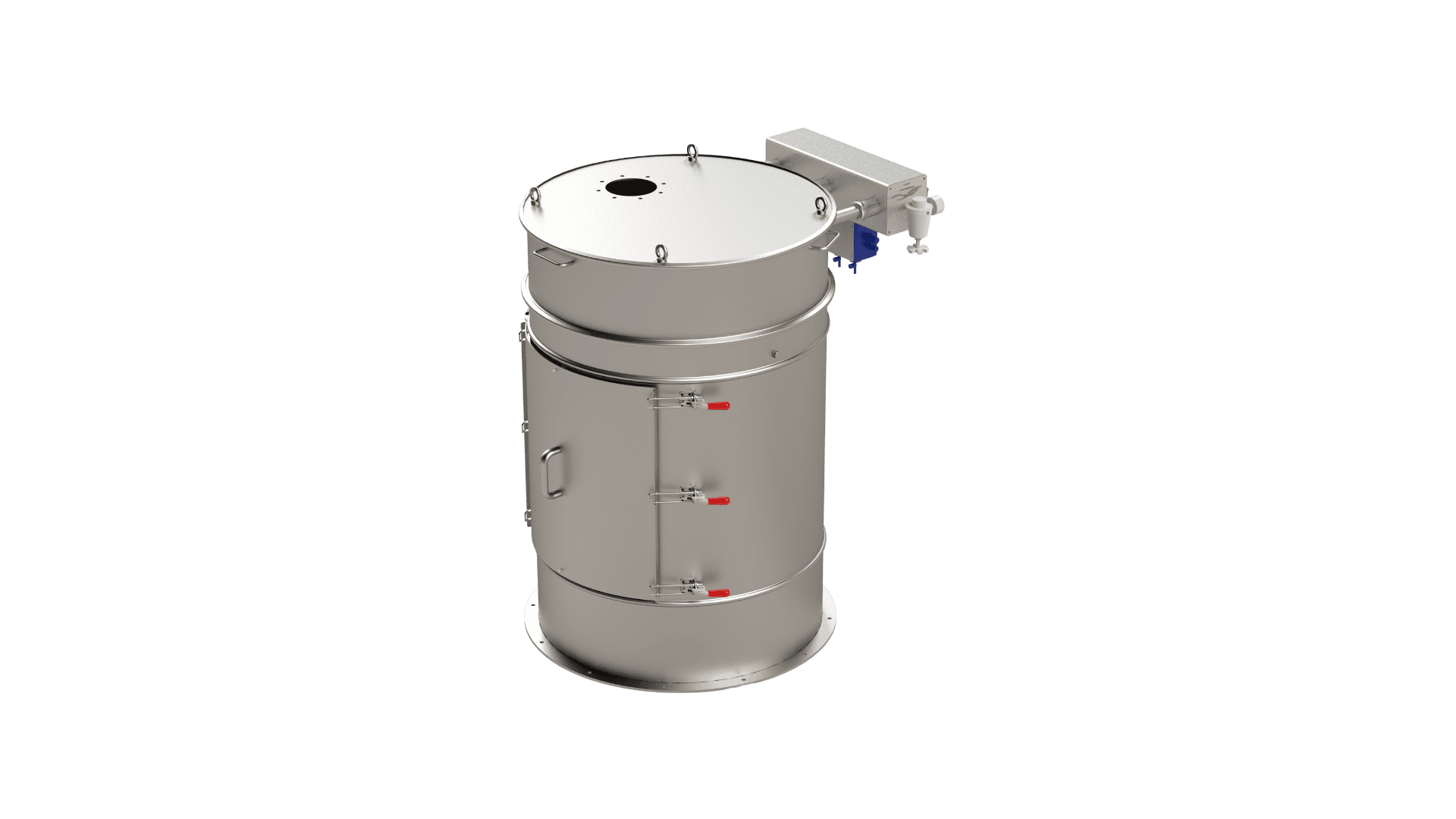

High separation efficiency for use in the food industry – the BVD bin vent filter

The BVD bin vent filters are used for the continuous venting of pneumatically filled containers. As cartridge or bag filters, they ensure high separation efficiency of dust and powdered products across nearly all technical applications. They are particularly well suited for use in the food industry. Food-grade filter cartridges or filter bags with bayonet fittings allow for a simple, safe, and tool-free replacement of filter elements.

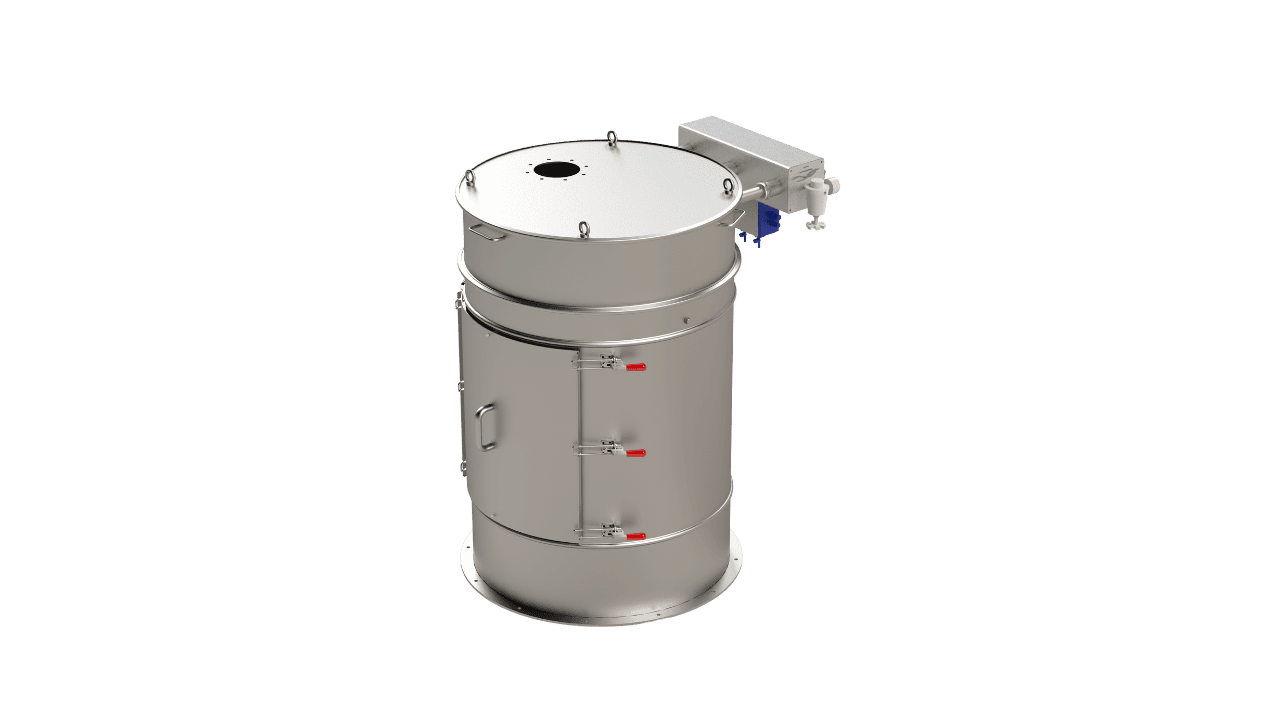

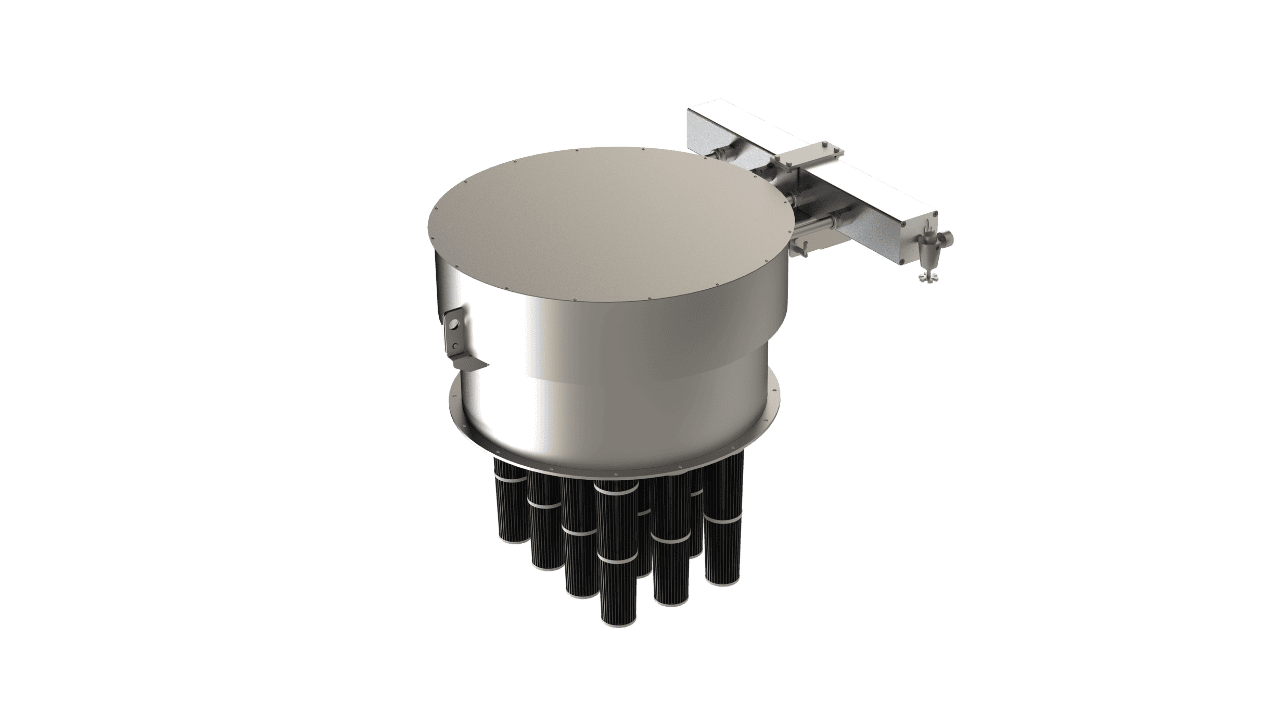

Continuous venting with the BVT bin vent filter

BVT bin vent filters are used for the continuous venting of pneumatically filled containers and silos. As cartridge filters, they ensure high separation efficiency for dust and powdered products across nearly all technical applications. They are especially well suited for use in the food industry. The filter cartridges and filter hoses with bayonet connection can be replaced easily, safely, and without tools.

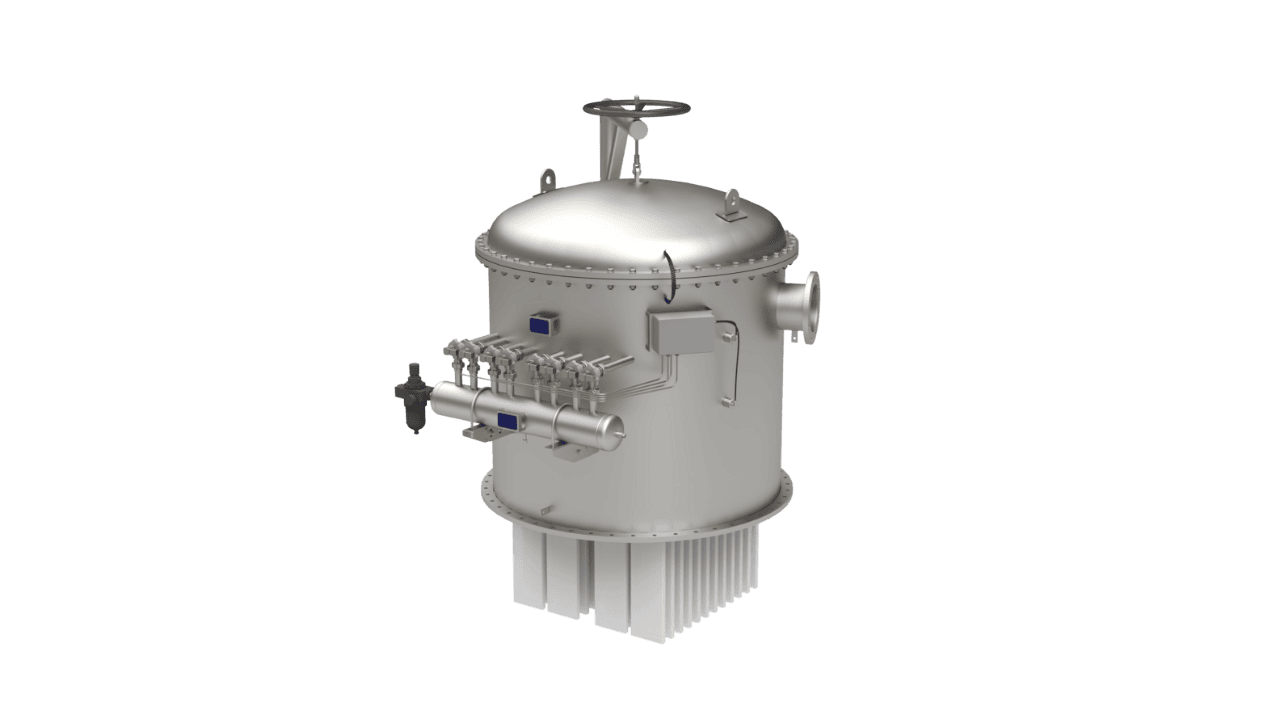

BVV bin vent filter for the separation of gases from bulk materials

BVV bin vent filters are used for the continuous separation of dry, powdery, and granular bulk materials from gases. They are mounted on containers and silos and can be equipped with flat or round filter bags as well as time- or differential-pressure-controlled pulse-jet cleaning systems.

Benefits

Special Highlights

Powerful

Filter areas of up to 146 m² ensure reliable operation even at high volume flows. High-quality filter media provide excellent separation performance.

Safe operation

Our filters are particularly well suited for continuous operation and can be equipped with differential pressure monitoring, which tracks their condition and indicates maintenance needs at an early stage.

Extensive range of accessories

A variety of filter media and materials are available, including options such as sound insulation or a foldable weather hood for safe, clean-side installation and removal of filter elements.

Application Areas

Industries

Our many years of experience in building state-of-the-art systems for the food and chemical industries, combined with our comprehensive expertise in raw material handling, make us an indispensable partner. With patented processes, turnkey solutions, and in-depth knowledge of industry-specific regulations – from explosion protection to the handling of hazardous substances – we implement your projects efficiently and in full compliance. This ensures the smooth and rapid planning, execution, and commissioning of your systems.

Need more details? Our contact person will be happy to assist you

Further topics you might be interested in

Explore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH