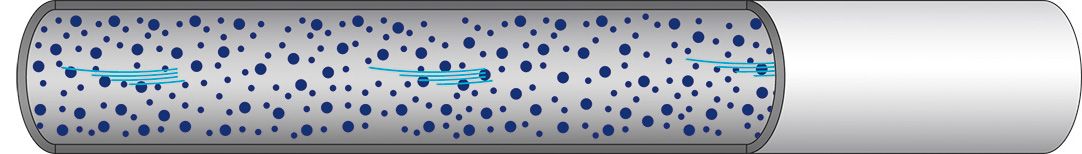

Dilute phase conveying

FOOD TECHNOLOGY CENTRE FOR THE FOOD INDUSTRY

The Food Technology Centre in Rödermark was specially designed for the requirements of the food industry and offers ideal conditions for trials on the processing of liquid and powdered raw materials. With an area of over 300 m² and a height of 10 m, trials can be carried out here not only on a laboratory scale but also with the real capacity of our customers. This is because no standard plant was permanently installed on the two-storey test area, but a modular system was developed that guarantees a high degree of flexibility.

You want to know how the chocolate flakes in your new recipe behave during mixing? Which type of conveying produces the least abrasion in one of your raw materials or which way keeps your agglomerates intact? Then simply use our technical centre.

Together with our technology centres in Friedrichshafen and Kassel, we form a technical network for handling high-quality bulk materials. While the plastics, chemicals and rubber division is covered in Friedrichshafen, the Kassel technical centre specializes in the mixing and compounding division.

Individual tests for your products

Test facilities for all process steps

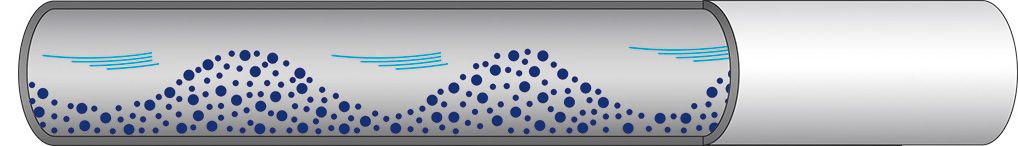

Plug conveying

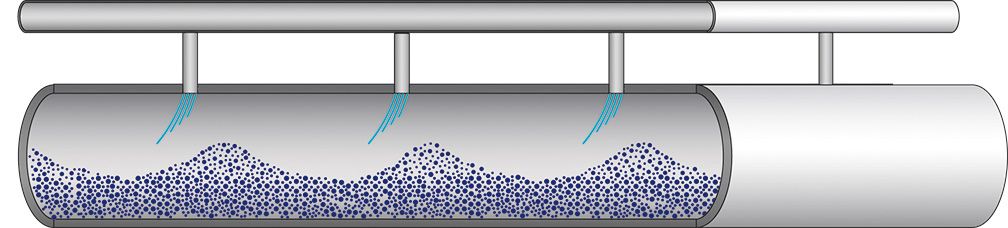

Secondary air conveying

Homogeneous mixing results

Efficient production lines with high availability and reproducible product quality can only be realized with optimal system technology and a process that is designed to meet the specific requirements of the individual product. We offer the following options for testing your perfect mix:

- Codos NT: open, continuously operating horizontal mixer or kneader with two intermeshing mixing-kneading tools.

- DymoMix: uniform wetting of dry materials with liquids as a pre-mixer (dough production) and for moistening dry materials

- Horizontal mixer: for mixing dry powders or with liquid injection up to chocolate mixtures

- Pneumatic homogenizing unit: gentle homogenizing of agglomerates and fine powders in the fluidized bed

- Screw belt mixer: pre-mixer for small footprints and optimum height utilization

- Cone mixer: for discharging powder mixtures without residues

Raw material preparation and conditioning

For an optimal and, above all, reproducible result of the final product, the general conditions should be constant. Therefore, the raw materials used must always be processed under the same conditions. There are basically three different ways of doing this:

- Hydration by DymoMix: Dry materials are hydrated with liquids in seconds, exposed to air, and mixed before being introduced into the actual dough-making process. This produces doughs that can · be used immediately or fed to the batch kneader or continuous kneader

- Tempering by PneumoTherm: for optimally tempered raw materials (heating/cooling), e.g. for flour cooling.

- Classification by sifters: protective sifting with inline sifters in various sizes and mesh sizes