Cooling Mixers

Technology that sets standards

Efficient cooling for demanding processes

Whether vertical, horizontal, or modular, Zeppelin cooling mixers offer powerful solutions for fast and controlled cooling of bulk materials in the plastics and chemical industries. With intelligent cooling technology, high mixing performance, and flexible application options, they ensure maximum efficiency in a wide range of applications—from PVC dry blends and compounding to technical plastics and WPC.

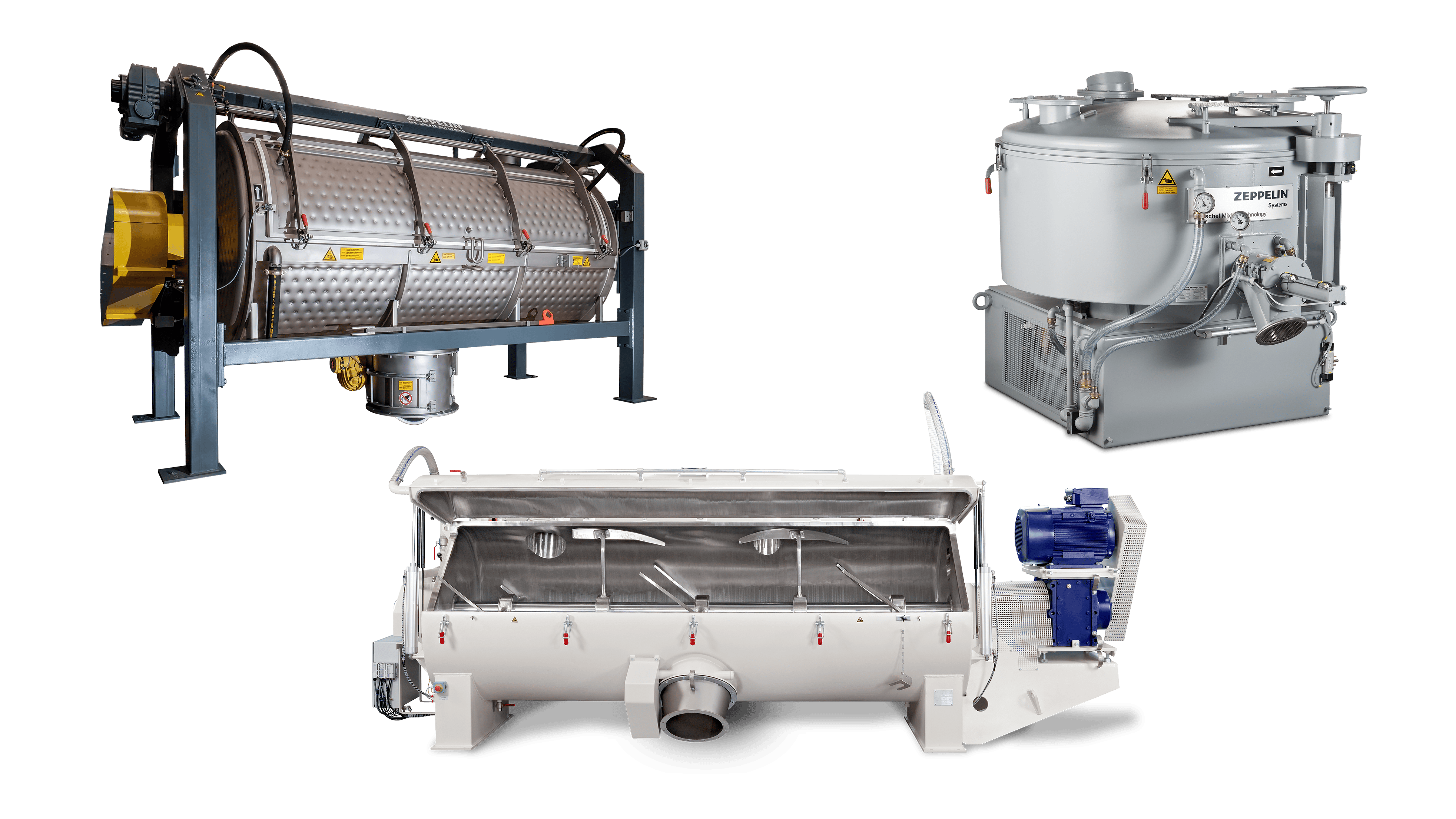

Our cooling mixers at a glance

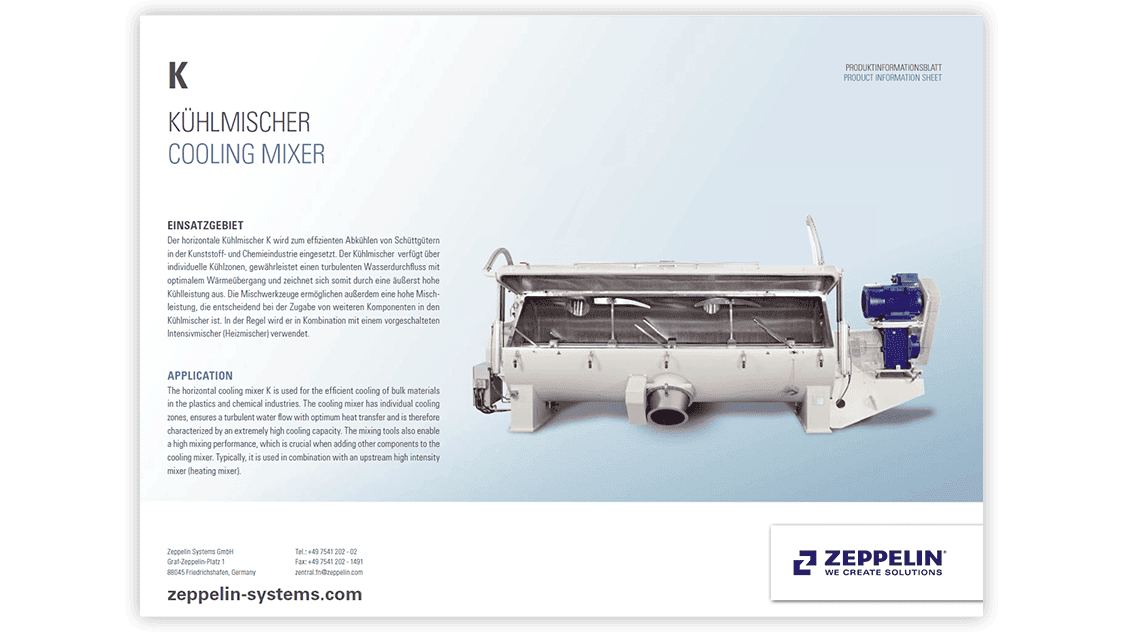

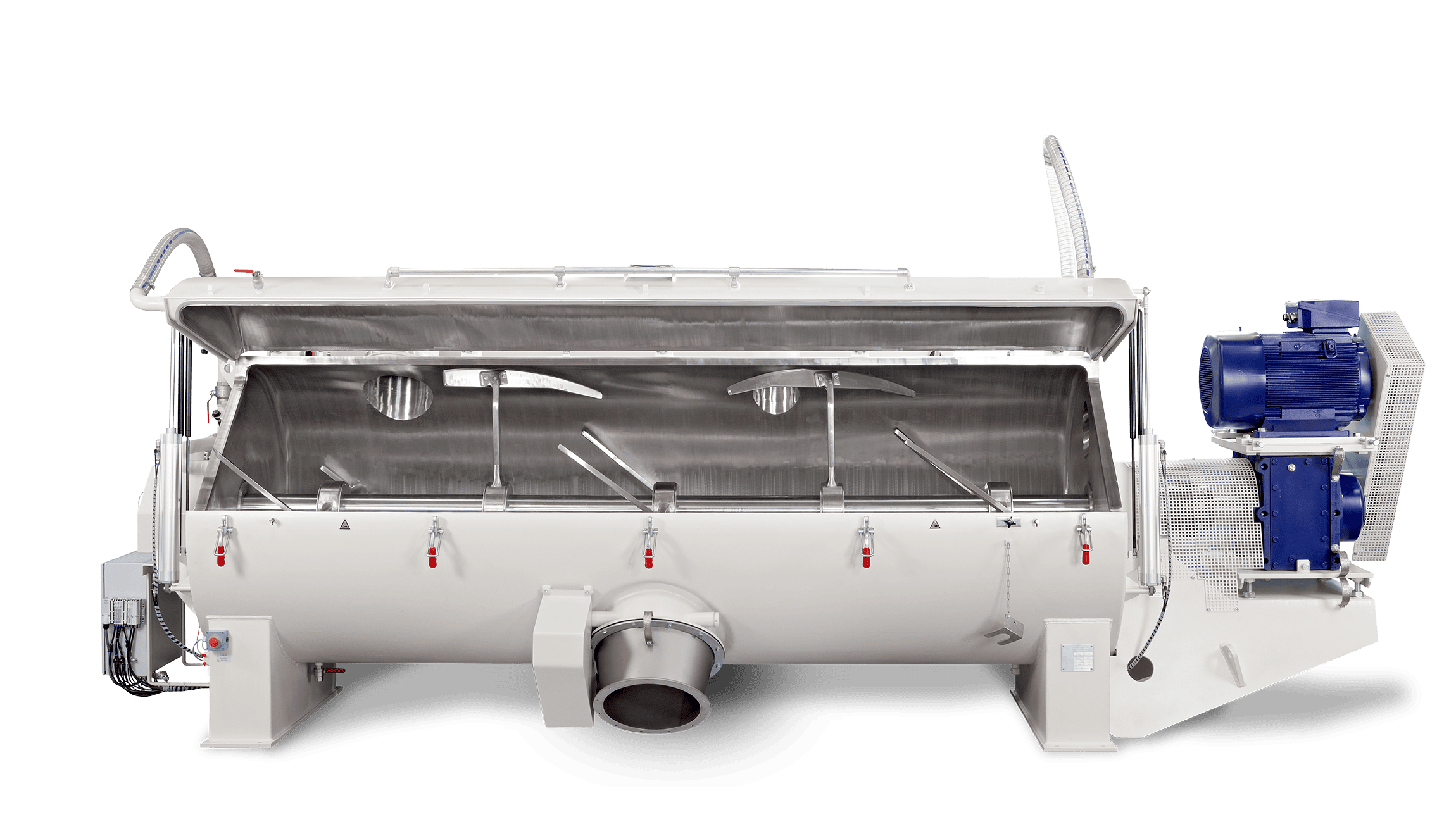

Horizontal Cooling Mixer K

Zeppelin Systems’ horizontal cooling mixer K is the high-performance solution for fast and precise cooling of bulk materials. Individually adjustable cooling zones and efficient heat transfer ensure maximum cooling capacity and process reliability – ideal for applications in the plastics and chemical industries.

Go to Horizontal Cooling Mixer K

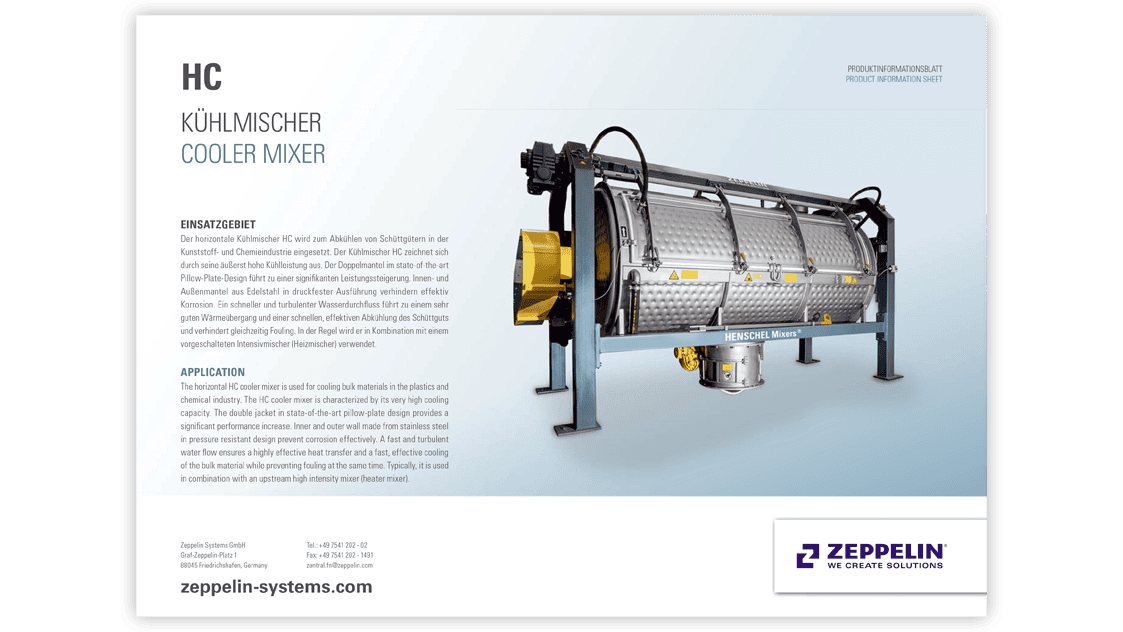

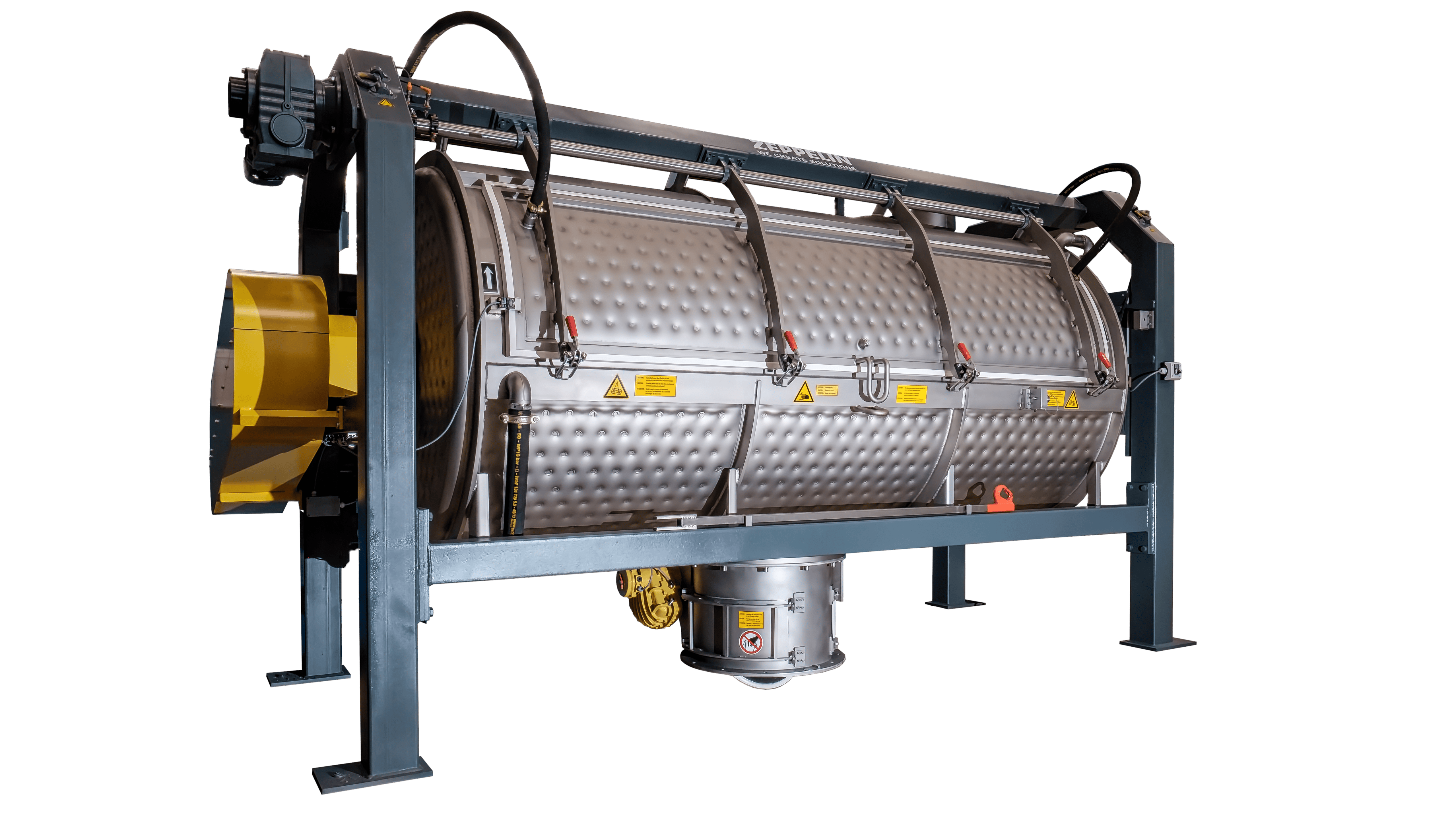

Horizontal Cooling Mixer HC

The horizontal cooling mixer HC ensures fast and efficient cooling of bulk materials thanks to its pressure-resistant double jacket in pillow plate design and turbulent water flow. In combination with a high-intensity mixer, it impresses with its high mixing performance in applications such as PVC dry blending, compounding, and WPC.

Go to Horizontal Cooling Mixer HC

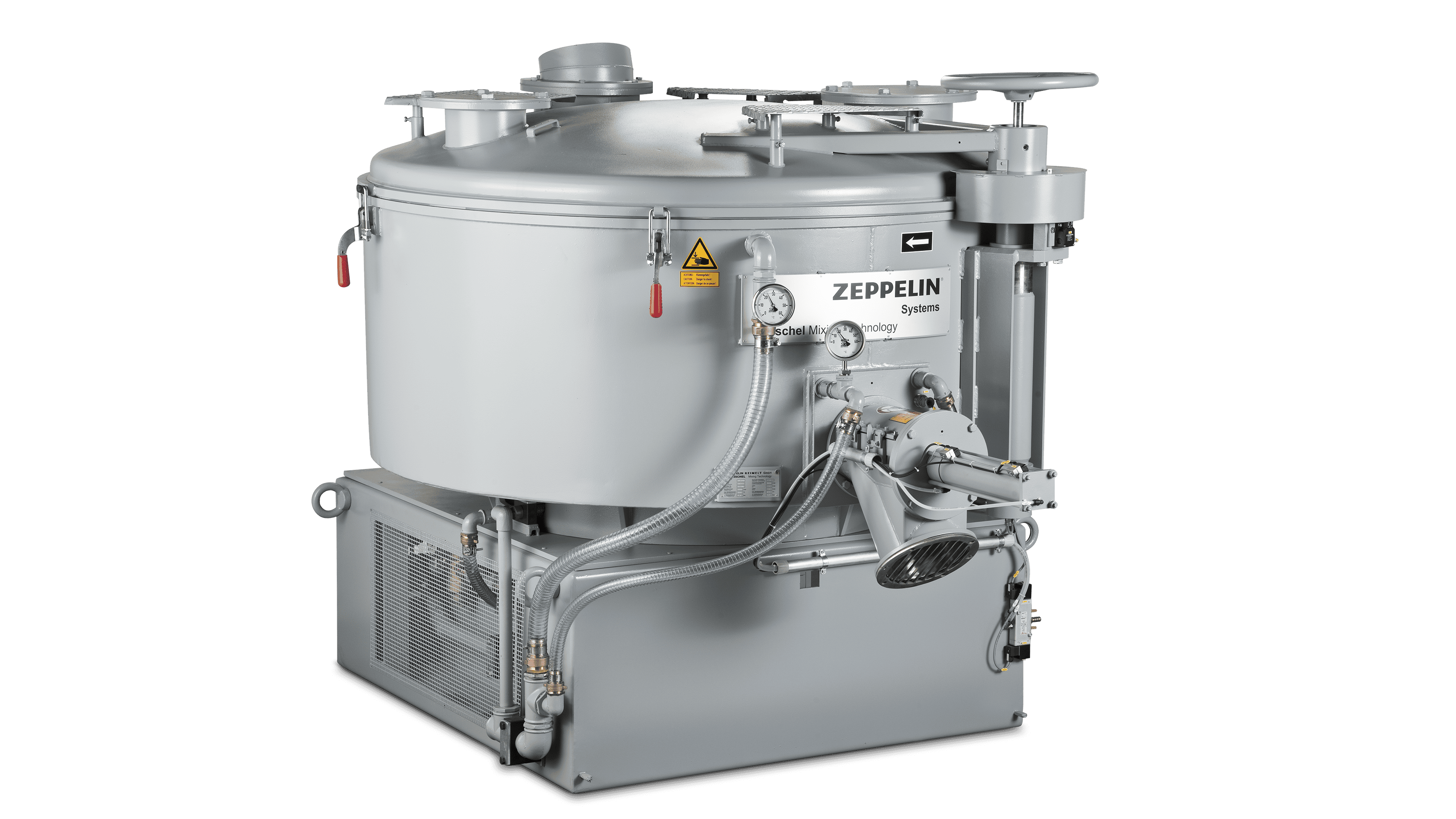

Vertical Cooling Mixer KM

The vertical cooling mixer KM impresses with its compact design, high performance, and easy cleaning—ideal for demanding mixing processes. In combination with a high-intensity mixer, it proves itself in applications such as bonding, compounding, masterbatch, PVC dry blend, battery compounds, engineering plastics, and WPC.

Go to Vertical Cooling Mixer KMApplication Areas

Industries

Plastics

Technical Plastics

Zeppelin Systems develops customized systems for technical plastics – from conveying to reactor integration. With many years of experience, we support you throughout the entire process: from planning and commissioning to service.

Go to technical plastics

Plastics

Compounding & Plastic Processing

Zeppelin Systems combines innovative technologies with decades of experience and over 10,000 reference plants – ensuring seamless processes from raw material management to packaging.

Go to compounding & plastic processing

Chemistry

Batteries

Zeppelin Systems develops customized, resource-efficient processes for battery slurry production – including a dedicated test environment to ensure optimal results.

Go to batteries

Chemistry

Dispersion Paints

With certified plant technology and comprehensive expertise, Zeppelin Systems offers maximum flexibility and safety across all processes in paint production.

Go to dispersion paintsNeed more details? Our contact person will be happy to assist you

Zeppelin Services

Service

360˚ Service

Zeppelin Systems offers you service with real added value. We deliver not only turnkey plants, but also complete systems, mixers, silos, and components – and support you throughout the execution of your project.

Go to 360˚ services

Technology

Technical Center for Mixing Technology

The technical center in Kassel offers the essential processes of mechanical engineering—in particular mixing technology—for the plastics processing and chemical industries. We develop new processes for processing and manufacturing sensitive raw materials for and in collaboration with our customers. Results can be immediately verified in our state-of-the-art laboratory.

Go to Technical Center for Mixing Technology

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutionsResources

Brochures for Download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH