Plants for battery mass production

Custom plant engineering and mixing solutions for the innovative production of battery materials

Safe, efficient, and resource-conserving production of battery materials

Thanks to our many years of experience with sensitive bulk materials and raw substances, we understand the challenges involved in producing battery materials. Whether you're working with wet or dry processes, Zeppelin Systems delivers safe, efficient, and resource-saving solutions tailored to your application.

From the raw material intake—whether virgin or recycled—through conveying and storage, all the way to mixing and precise dosing into the calender, we provide an end-to-end, process-reliable system.

A key advantage for our customers: Zeppelin Systems offers a dedicated technical test environment where different machine settings, formulations, and process parameters can be tested and optimized together—ensuring the best solution for your production needs. We Create Solutions!

Unsere Zertifizierungen

Einsatzbereiche

Rohstoffaufbereitung

Elektrodenherstellung

Rohstoffrecycling

Precise raw material handling is crucial

Process expertise sets new standards

Zeppelin Systems represents the first step in the battery production process chain. From the intake of raw materials or recyclates, through conveying and storage, to the mixing process and precise dosing into the calender—our plant concepts provide the ideal foundation for handling sensitive materials and executing the critical mixing step.

Everything from a single source – reliable, efficient, and precisely tailored to your requirements.

Process solutions for battery production

Storage and discharge tailored to your needs

Safe material feeding and storage of raw materials play a crucial role in the production of battery materials. Zeppelin Systems offers comprehensive raw material logistics—from sacks, drums, and big bags to full truck unloading—always tailored to the specific, including abrasive, properties of the raw materials.

Our systems are designed in accordance with locally applicable explosion protection regulations. Carefully aligned containment concepts, adapted to prescribed occupational exposure limits, ensure optimal operator safety—even when handling toxic substances.

With our Smart Storage Solution, you're also equipped for Giga Factories. Storage volumes can be easily tailored to your specific needs and scaled up at any time—helping to prevent material shortages caused by disrupted supply chains.

For fast, efficient discharge—without bridging, sticking, or leftover residues—you can rely on our specially developed discharge aids, ensuring smooth and reliable operations.

Precise conveying

We analyze the bulk material properties of your products and develop the optimal conveying system tailored to your specific requirements.

Our technologies are precisely adapted to your application—whether pressure or vacuum dilute-phase conveying, secondary air systems, or dense-phase conveying. Your needs also guide the choice of materials: in addition to metal pipelines, we offer rubber-lined piping for safe handling of materials that tend to stick to metal surfaces. Even abrasive raw materials can be conveyed efficiently with the right material selection.

For precise conveying of powders and granulates containing fine particles, we’ve developed the vacuum conveying unit. Its large filter surfaces with efficient cleaning ensure high performance for powdery products. The system offers safe vacuum conveying, is available in various conveying capacities and batch sizes, and stands out for its compact design. It can be used as a standalone unit or integrated into central feed systems.

Effective filtration

Whether from sacks, big bags, or octabins—Zeppelin Systems ensures the dust-free feeding of raw materials by relying on our in-house developed dedusting systems or by partnering with renowned filter manufacturers. This allows us to respond precisely to your specific requirements and always select the most suitable solution.

Our jet filters with automatic cleaning, for example, prevent unwanted material loss by returning collected dust directly into the process—eliminating the need for frequent filter changes. This not only reduces maintenance costs but also minimizes product waste.

In addition, our Safe Change concepts ensure that operators are protected from exposure to toxic and respirable substances—guaranteeing safety and compliance at every stage of your process.

Accurate weighing and dosing

No tolerance for tolerances! At Zeppelin Systems, this guiding principle has led to the development of ultra-precise weighing and dosing systems. Depending on your specific requirements, we offer fully automated systems for small components with gram-level accuracy, as well as high-performance weighing systems for dosing and weighing difficult-to-handle raw materials in the tonnage range.

Our dosing systems, screws, and scales meet the highest demands in terms of dosing speed, weighing accuracy, and ease of maintenance. Every raw material is metered with pinpoint precision and discharged reliably. To support this, we offer a wide range of mechanical and pneumatic discharge aids—from vibrating bottoms to aeration cones and fluidized beds.

Most importantly: full traceability of all raw materials used, comprehensive monitoring of process parameters, and accurate, recipe-compliant dosing are essential to ensuring the quality of the electrode slurry and the battery cell. These factors directly influence the performance and service life of the battery cell being produced.

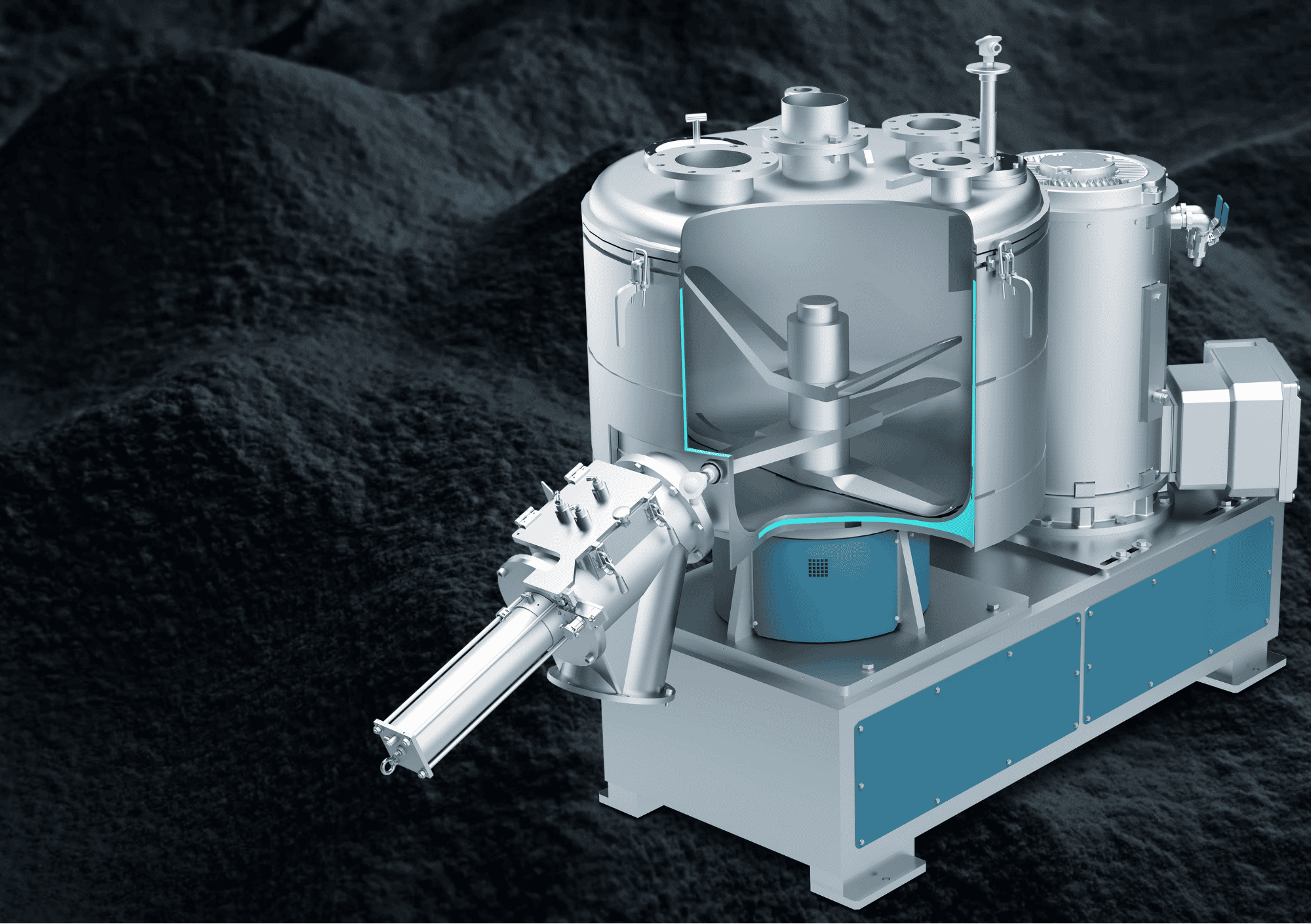

Innovative mixing of battery materials

Zeppelin Systems mixers have been established in industrial mixing technology for 70 years and are used in various industries for different mixing processes.

The Zeppelin FM intensive mixer is ideal for the high-quality, reproducible, and safe production of battery compounds using dry and semi-dry mixing processes. High speeds, the design of the mixing tool, and the construction of the mixing vessel achieve extremely high shear rates. These enable highly efficient dispersion and homogenization of the raw materials. Different process parameters (e.g., individual shear rates, precisely controllable temperature profiles, etc.) allow nanoparticulate conductive additives to be effectively dispersed and finely distributed, and binding materials to be specifically activated and fibrillated. Depending on the base materials, the bulk density and energy density can also be increased. In addition, the FM intensive mixer from Zeppelin Systems offers individual wear protection, which ensures a long service life even with abrasive raw materials.

Precise liquid dosing

To ensure precise liquid dosing, Zeppelin Systems has set a new benchmark with its innovative Liquid Dosing System (LDS). This system enables high-accuracy dosing and weighing of both low- and high-viscosity liquids.

The LDS guarantees maximum operational safety and availability, while ensuring consistent recipe quality and full traceability of all raw materials used. Its modular design allows for easy retrofitting into existing systems or seamless integration into plant expansions—making it a future-ready solution for modern battery material production.

Dosing unit for calender feeding

For the continuous and consistent feeding of electrode slurry onto the calender rolls, a special dosing unit with a feed chute and continuous level monitoring has been developed. The chute is directly coupled to the calender roll and can move linearly along with it.

By ensuring that material is always available in the chute, the system prevents the calender rolls from running empty. The optimized geometry of the chute effectively prevents bridging, while significantly reducing the line load on the calender rolls—ensuring smooth, uniform coating and improved process reliability.

Test centers for the safe production of battery materials

Zeppelin Systems operates three test centers where process-critical steps in the production of battery materials can be tested and refined. Both the mixing technology and the overall plant setup—as well as the mixing process itself—can be thoroughly evaluated and optimized. In some cases, these trials are conducted at full industrial scale, ensuring a high degree of reliability and significantly reducing uncertainties during scale-up.

Test series for battery materials

At our mixing technology test center in Kassel, processes are tested and further developed using individually configurable mixers from laboratory scale to pilot and full production scale. The insights gained from these trials form the basis for customer-specific machine designs and innovations that are developed and established in mixing technology. Comprehensive test series have been conducted for various anode active materials (AAMs) and cathode active materials (CAMs), including LFP, NCA, NMC, SiC, SiOx, as well as a wide range of graphites and binders. These tests were carried out in collaboration with renowned industry customers and leading international research institutions.

Real-world testing of raw material behavior

At the Friedrichshafen test center, the behavior of various raw materials can be examined under real-world conditions—including conveyability, fluidization, caking tendencies, discharge characteristics, and potential changes to product or particle properties.

A dedicated test setup is currently being developed here to specifically test calender dosing of different AAM and CAMmixtures for Zeppelin Systems customers. In addition, the in-house bulk material laboratory conducts a wide range of product analyses, including moisture measurement, particle size and distribution, bulk density determination, and shear tests.

This data forms the foundation for a safe, reliable, and sustainable battery material production process.

Need more details? Our contact person will be happy to assist you

Services

Discover our comprehensive range of services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs — and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutions

Service

Service without compromise

In the 21st century, optimization often means automation. We ensure that your automation project is a complete success in terms of both efficiency and cost-effectiveness. To achieve this, we rely on cutting-edge control systems whose open architectures prepare you for the challenges of tomorrow—and beyond.

Go to servicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH