Horizontal Cooling Mixer HC

Stays cool – for top products

For a wide range of processes and highest demands

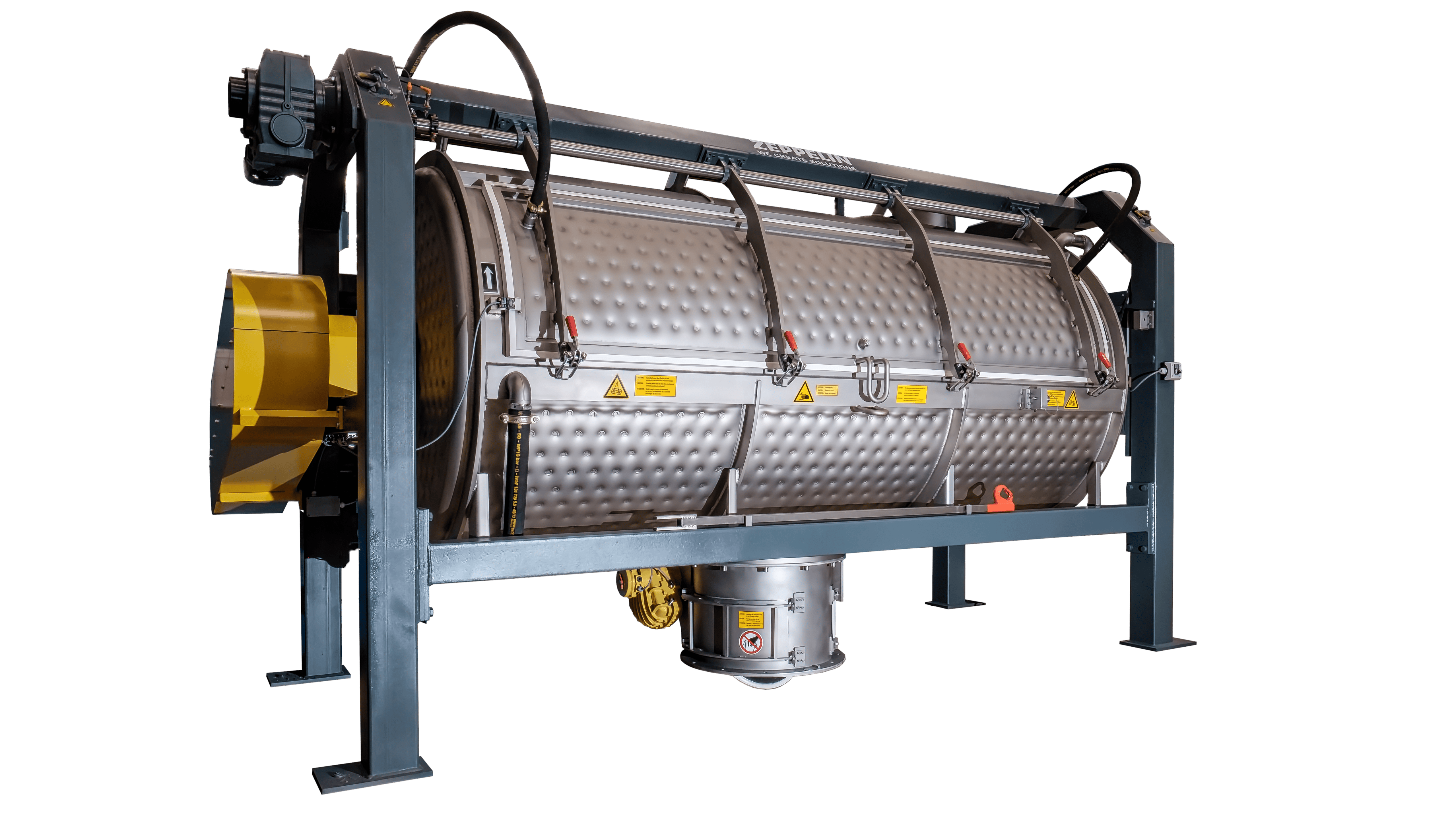

The horizontal cooling HC mixer is used for efficient cooling of bulk materials in the plastics and chemical industries. The double jacket in a state-of-the-art pillow plate design is pressure-resistant up to a maximum of 7 bar. A turbulent water flow guarantees optimum heat transfer and fast, effective cooling of the bulk material.

The mixing tools also enable high mixing performance, which is crucial when adding further components (e.g., during double batching) to the cooling mixer.

In combination with a high-intensity mixer, it has proven itself in various applications such as: PVC dry blend, compounding, WPC, etc.

Key advantages at a glance

- Short cooling times

- Pressure-resistant double jacket (max. 7 bar)

- Excellent mixing quality

- Gentle material handling

- Low dead space design

- Excellent residual emptying

- Intelligent design for minimal maintenance costs

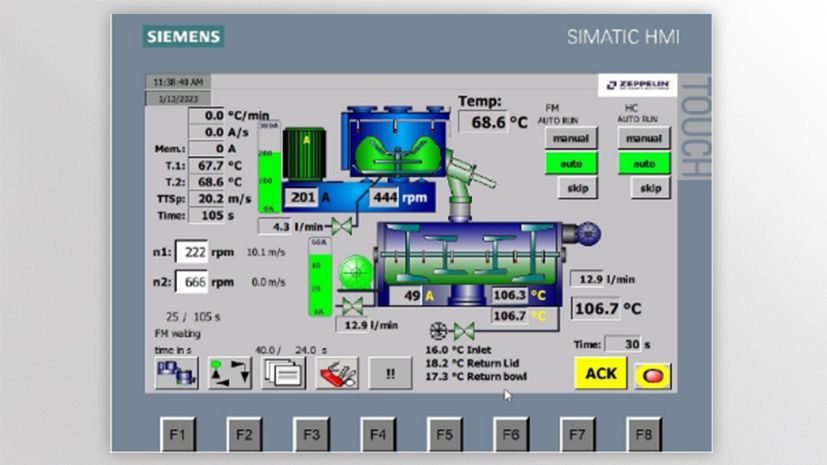

- Control concept for intuitive operation

- Configurable for a wide range of applications in the fields of plastics, chemicals, minerals, and dyes

- Consistent cooling performance by preventing fouling

- Expandable with extensive options (chopper, liquid addition, etc.)

Application areas

Plastics industry

In plastics processing, cooling mixers are used after hot mixing to bring the heated material to processing temperature quickly and in a controlled manner. This prevents thermal damage and optimally prepares the mixed material for further processing.

Chemical industry

In the chemical industry, cooling mixers control exothermic reactions and gently cool sensitive substances after mixing. This not only improves product stability, but also significantly increases process safety.

Benefits

Special Highlights

Long-standing expertise

With over 70 years of experience in process engineering, Zeppelin Systems offers proven solutions for demanding mixing processes. This expertise flows directly into the development and optimization of the cooling mixer HC.

Global presence

More than 18,000 mixers installed worldwide speak for the reliability and performance of our technology. The cooling mixer HC is an established system that enjoys global trust.

Flexible sizes

The cooling mixer HC is available in six sizes ranging from 1,700 to 8,500 liters and can be optimally adapted to different production requirements – for maximum efficiency and scalability.

Product details

Large lid opening

Good accessibility for cleaning and maintenance purposes.

Dead space free discharge

Discharge plate adapted to the inner contour of the bowl.

Intuitive mixer control

The mixer control system features an intuitive user interface that makes it easy to operate in both manual and automated modes.

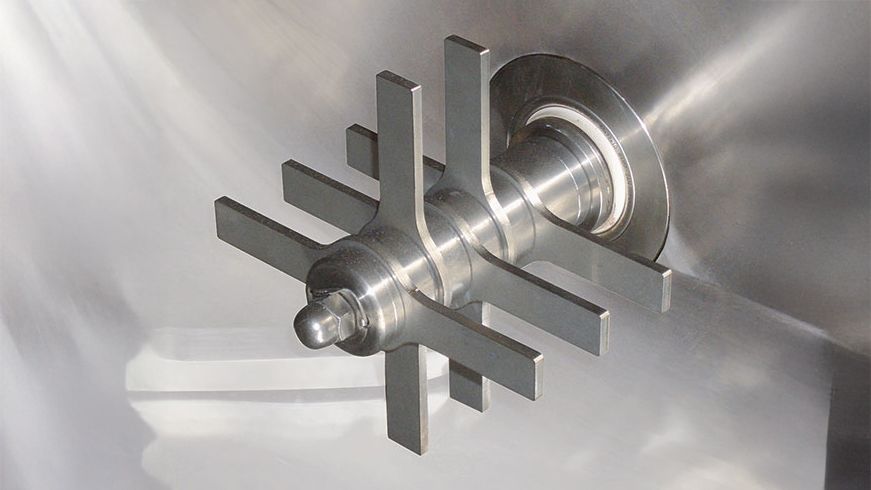

Pillow plate design

Double jacket in pressure-resistant pillow plate design, inner and outer jacket made of high-quality stainless steel

Accessories and options

Perfect additions for cooling mixer HC

We offer various accessories and options for seamless integration and flexible use of our cooling mixer. These include, among others:

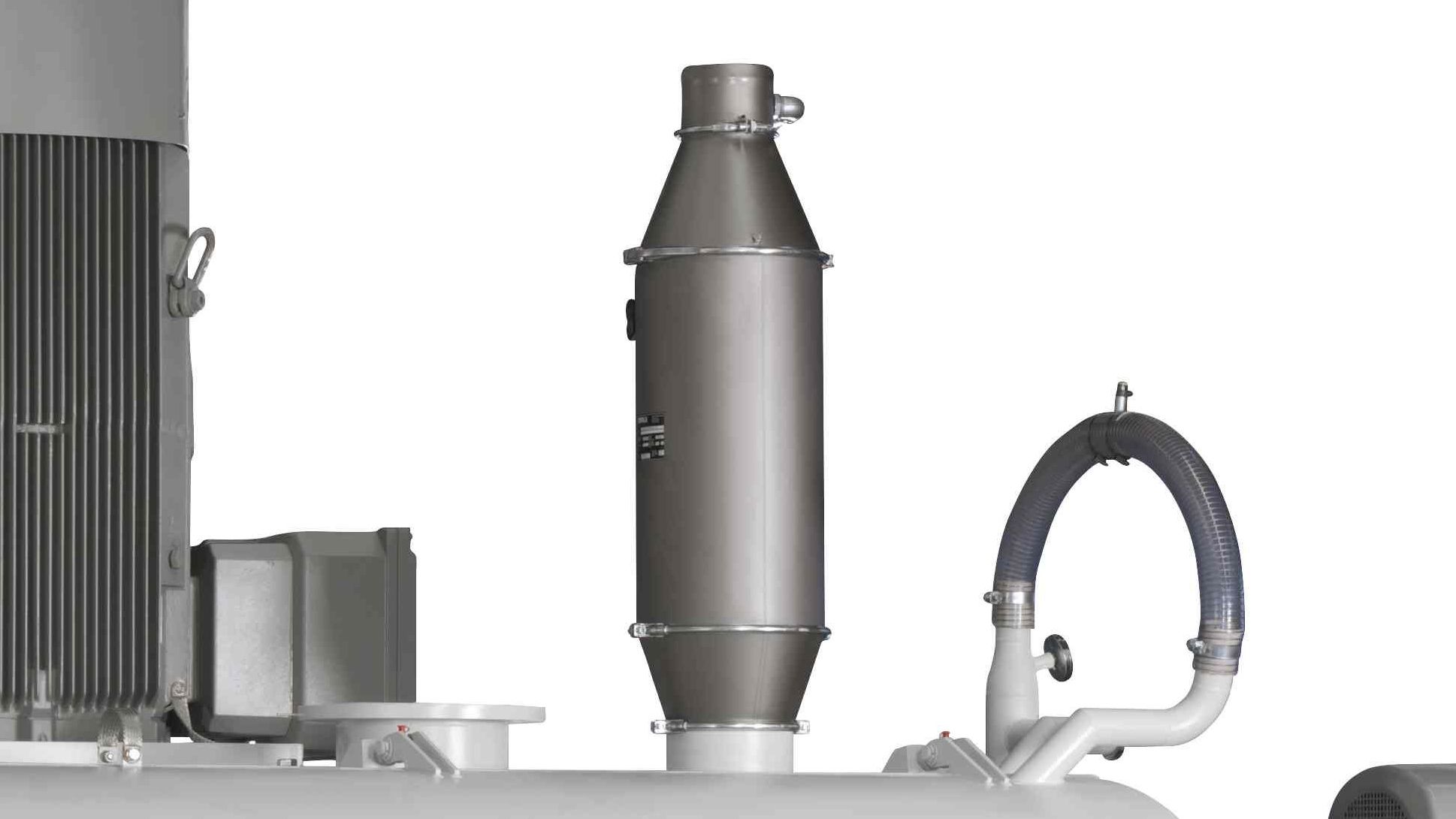

Jet filter

Filter with automatic cleaning for ventilating the mixer and for fast, dust-free removal of air during filling.

Chopper

Chopper as agglomerate crusher and for increased dispersion performance. The amount depends on the application and size.

Need more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Resources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH