Water Mixing Unit (WMU)

The right dose and mix make all the difference

The precise water dosing for your application

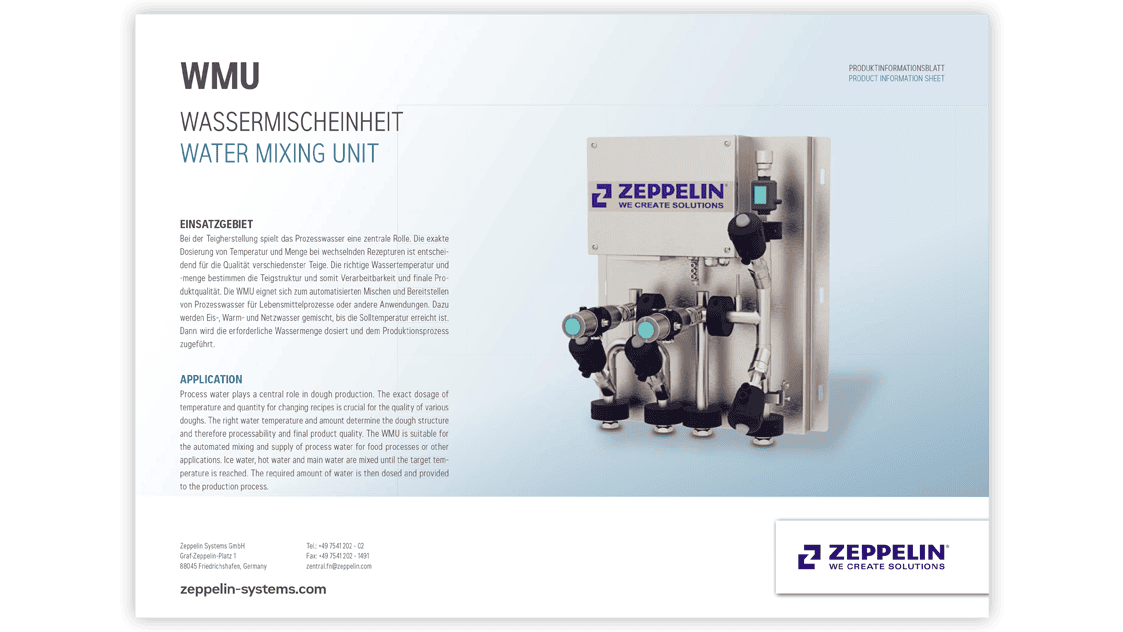

In dough production, process water plays a central role. The precise dosing of temperature and quantity with varying formulations determines the quality of the dough. The correct water temperature and amount determine the dough structure, and thus the processability and final product quality. Our Plug-and-Play Water Mixing Unit (WMU) is quickly deployable and suitable for automated mixing and providing process water batches for food processes or other applications. Ice, warm, and mains water are mixed until the target temperature is reached. The required amount of water is then dosed and supplied to the production process.

Special Highlights

- High Dosing Accuracy

- Durable and Low Maintenance

- Good Accessibility

- Integrated Small Control

- Drinking Water Approval

Product Details

Perfect Conditions for High-Quality Food

Good raw materials are the foundation for perfect food, and water is one of the most important raw materials for the industry. Zeppelin Systems ensures the right conditions with its water mixing unit, precisely dosing water at ideal temperatures!

Sizes

Throughput 3600 l/h

Application Area

Automated mixing and dosing of water at the required temperature and quantity for food processes or other applications.

Pressure Range

4-6 bar liquids, 6-10 bar control air

Temperature Range

Ambient temperature: 1°C to +50°C

Materials

Product-contacting parts made of stainless steel, suitable for drinking water

Drive

Electric, pneumatic

Simple to use – impressive in operation

Processes and Applications

The WMU is ideal for the automated mixing and provision of process water batches for food processes or other applications, ensuring precise liquid dosing and exact liquid temperature control:

Batch Dosing of Liquids

Benefits

Our Advantages for the Industry

Food Industry

No other company has as many decades of experience in the precise delivery of raw materials in the food industry as we do. This applies to handling, dosing, mixing, and controlling these processes. Of course, this also applies to the delivery of the raw material water. Our Water Mixing Unit (WMU) impresses with:

- High Dosing Accuracy

- High Throughput

- Space-Saving

- Easy to Install

- Flexible Solution

Need more details? Our contact person will be happy to assist you

Our Customer Services for You at a Glance

Show all Customer ServicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH