Liquid Dosing

Solutions for liquid dosing

Customized dosing systems for every industry

Precise solutions for every industry – from light to highly viscous!

Zeppelin Systems offers a selection of suitable methods for dosing liquids and temperature-controlled masses, such as volumetric or gravimetric measuring systems. Our solutions ensure maximum precision and efficiency for your specific requirements.

From temperature control and dosing of drinking water batches in the food industry to dosing with high flow rates of highly viscous liquids (liquid rubber/polyvest) in the rubber and tire industry, we have the right solution for your application.

Our liquid dosing solutions at a glance

Water Mixing Unit WMU

In dough production, process water plays a central role. Here, the precise dosing of temperature and quantity with varying formulations determines the quality of the doughs.

To the Water Mixing Unit

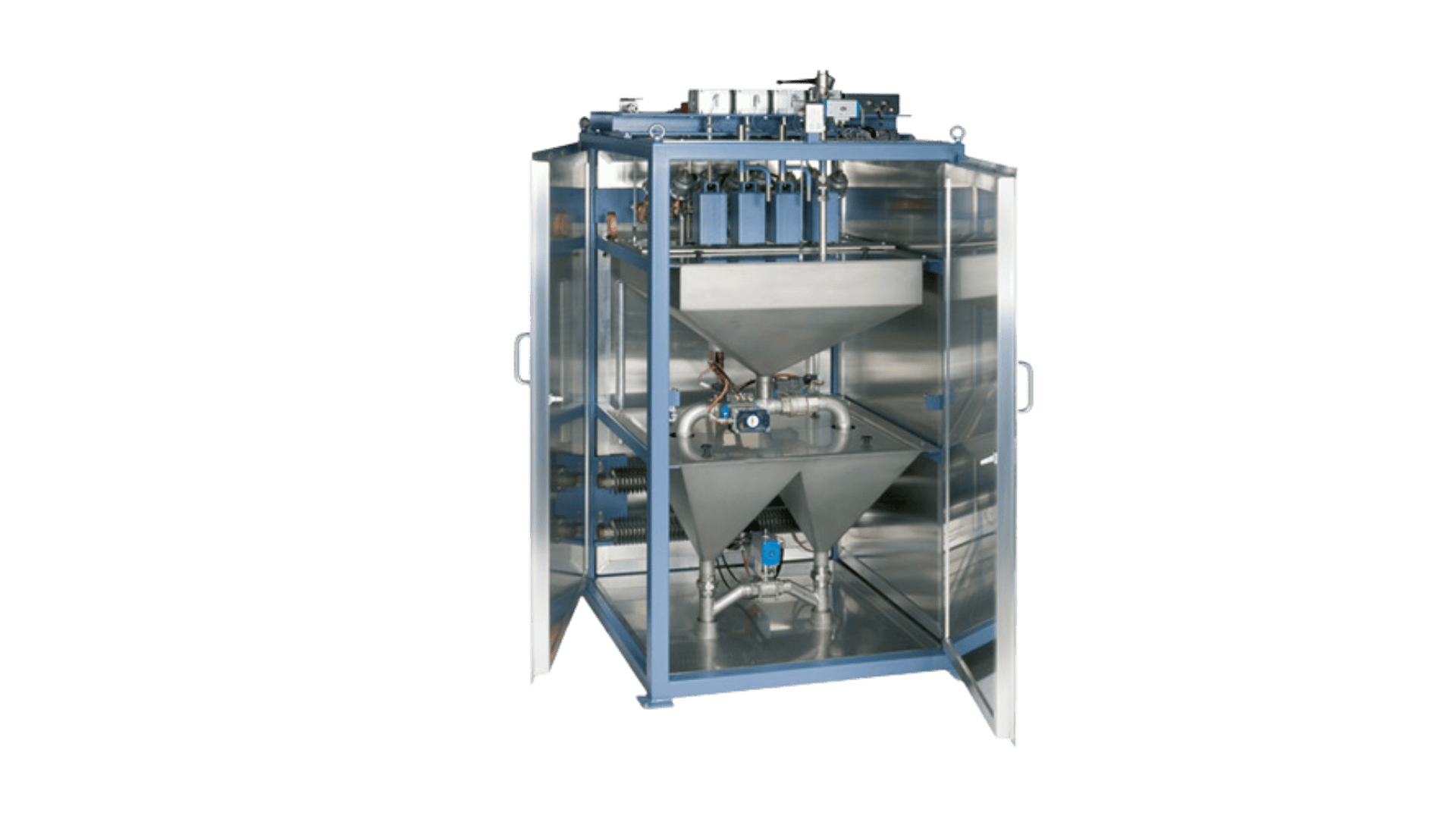

Liquid Weighing System LWS

The different flow characteristics are compensated for by heating the scale and by the degree of opening of the metering valves. The system offers precise weighing thanks to separate angle seat piston valves with stroke limitation for coarse and fine flow.

To the Liquid Weighing System LWS

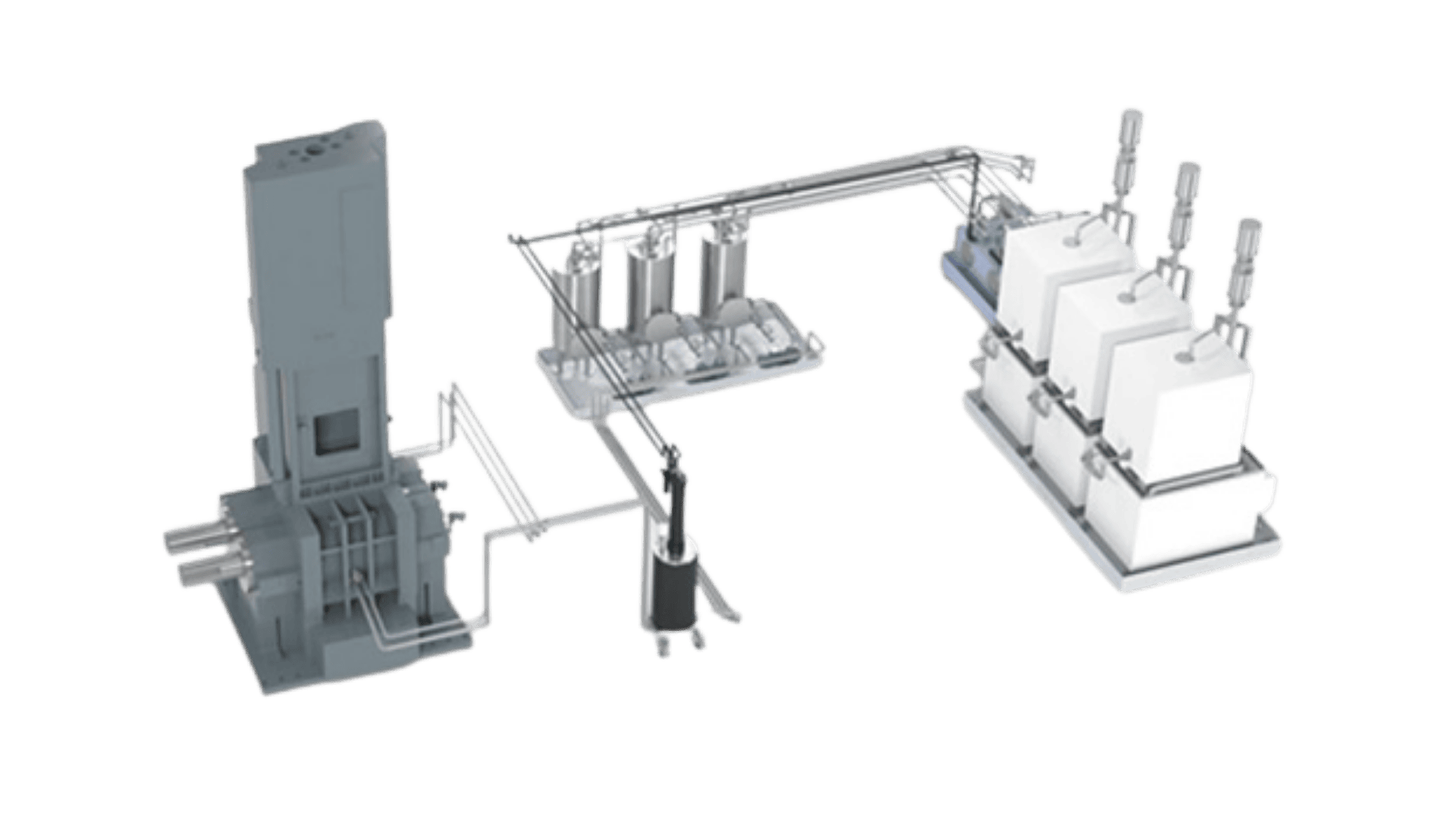

Liquid Dosing Station LDS

The Liquid Dosing System (LDS) is a robust, modularly expandable dosing system. It enables accurate volumetric batch dosing of up to 36 low- to high-viscosity liquids with high flow rates in a closed system up to the mixer line.

To the Liquid Dosing Station LDS

Liquid Dosing Cylinder LDC

The Liquid Dosing Cylinder (LDC) is the heart of the Liquid Dosing System (LDS). The LDC is used in mixing processes for rubber production. It performs volumetric dosing, conveying, and injection of liquid media. Typical media include oils, silanes, antioxidants, liquid rubbers, resins, solvents, and accelerators.

To the Liquid Dosing Cylinder LDC

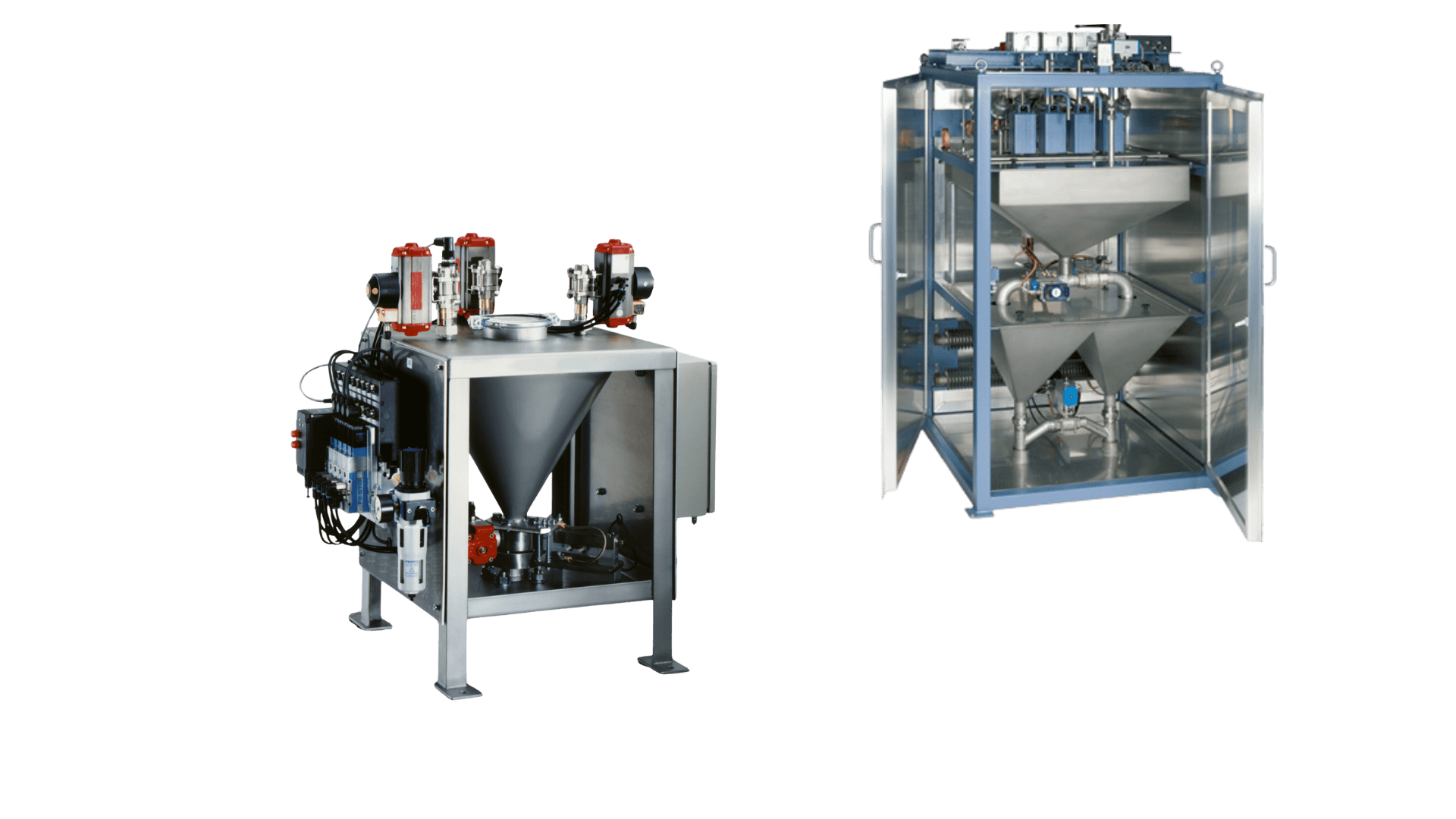

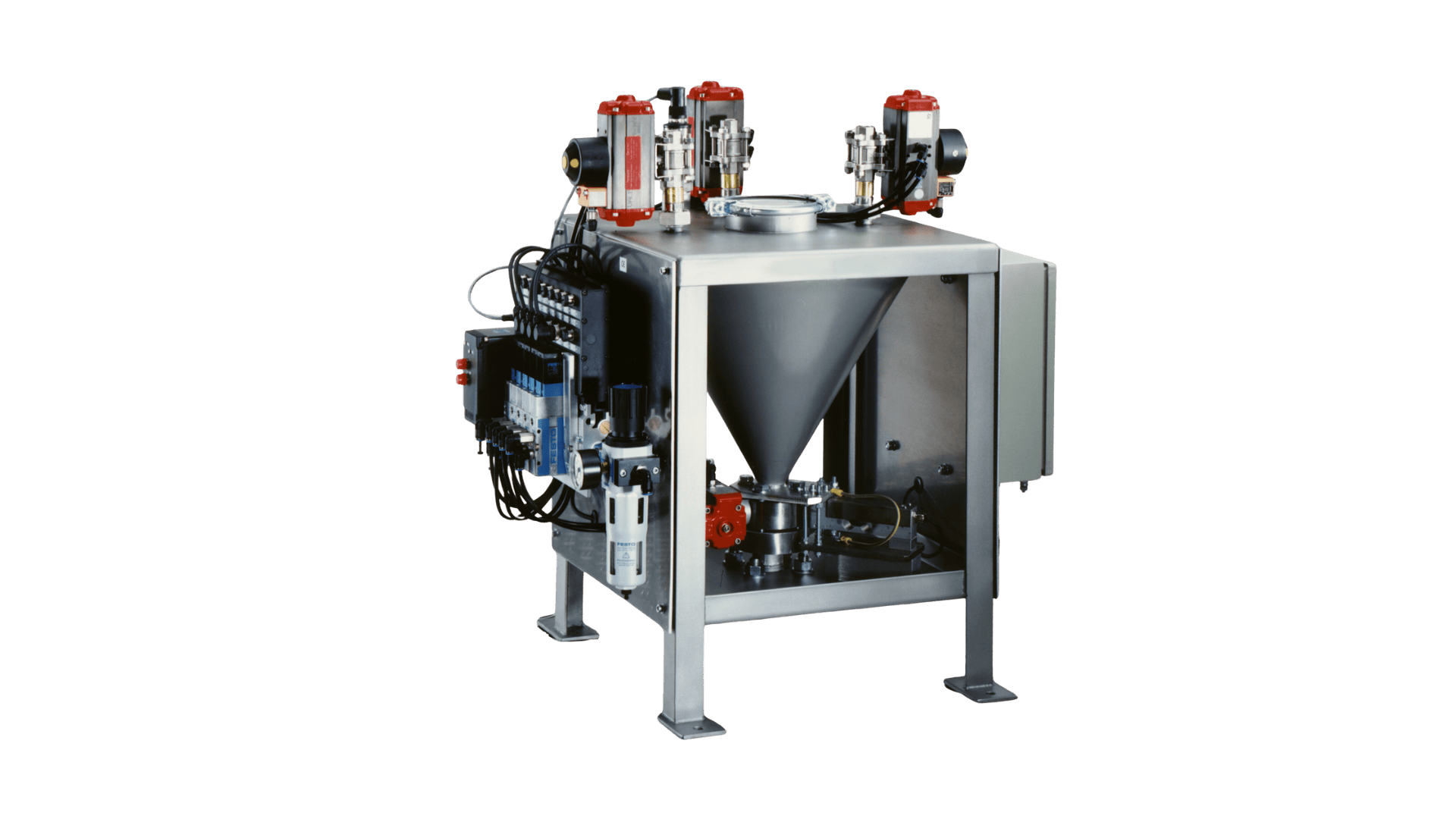

Liquid Scale FLW

Zeppelin Systems' liquid scales are suitable for gravimetric dosing of liquids for applications in the plastics, rubber, and tire industries that do not involve complex or hazardous requirements.

To the Liquid Scale FLWApplication Areas

Industries

Food

No other company has as much experience in building modern systems for the food industry as Zeppelin Systems. Every step in raw material handling – from intake and storage to conveying, conditioning, dosing, and perfect mixing – has been refined over many years. The result: seamlessly integrated systems from a single source.

Go to food industry

Plastics

Every Zeppelin system for plastics processing is tailored to your specific requirements. You benefit from our decades of experience and our proprietary, innovative processes and technologies developed specifically for the industry.

Go to plastics industry

Rubber & Tire

As proven process experts, we know every detail of the workflows in the rubber and tire industry. That’s why our well-engineered solutions deliver measurable benefits across the entire value chain – all the way to the recycling of used tires.

Go to rubber & tire industryWant more details? Our contact persons will be happy to help you.

Ingo Pütz

Global Market Manager Sales Food Processing Plants

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH