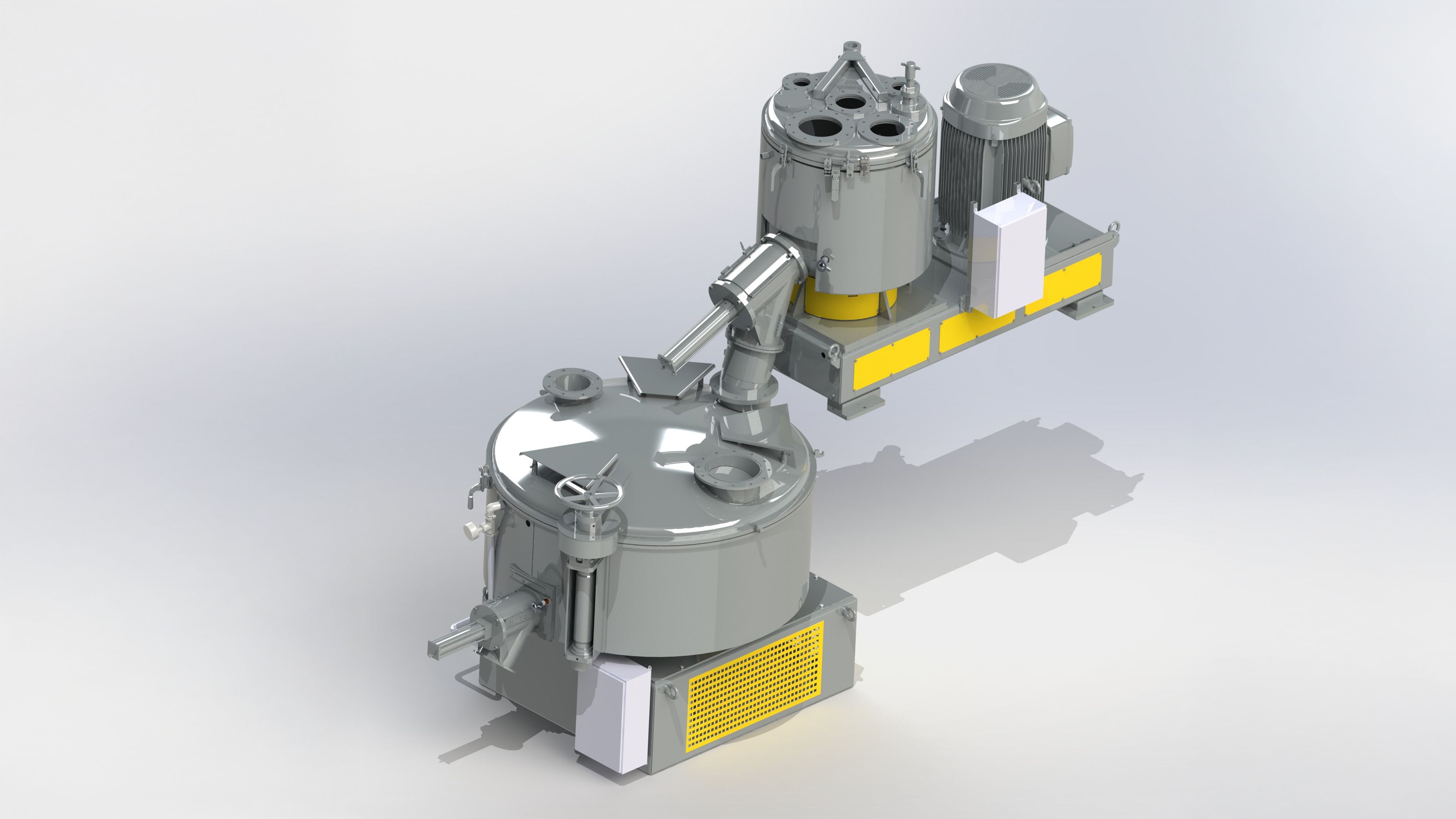

High-intensity mixer FM

For a wide range of processes

Intense mixing performance for the highest demands

The high-intensity mixer FM combines fast and intensive homogenization with maximum mixing performance – ideal for applications such as dispersing, stabilizing, coating, coloring, comminuting, drying, agglomerating, and heating. Whether for compounding, masterbatch, battery compounds, or engineering plastics, the FM has proven itself in a wide range of industries.

Thanks to fast-rotating mixing tools with peripheral speeds of up to 60 m/s, you can achieve excellent homogenization in the shortest possible time. The process control can be individually adapted – thanks to a flexible variant tool, freely configurable tool options, and a frequency-controlled motor.

A side discharge with a permanently screwed inspection opening (optionally with cleaning package) enables quick emptying and facilitates cleaning and maintenance. Heat is introduced via friction, ensuring short heating times and high heating performance.

Application areas

PVC

Perfectly suited for all PVC formulations at maximum performance – speckle-free, dried dry blend with ideal flowability guaranteed

- Typical applications: SPC dry blends with more than 300 phr filler, foam sheets, transparent medical films

- PVC-P also for mixtures with extremely high plasticizer content with Shore < 50

- Excellent dehumidification performance with the innovative Vent Tec aspiration systems

- 100% reproducibility of product quality

- Minimization of fluctuations in the downstream process

- Safe operation in compliance with ATEX guidelines

Bonding of powder coatings

Our perfected bonding process for the production of metallic powder coatings sets standards in the industry. High-intensity mixers with intelligent control technology offer the ideal solution for the special processes and requirements of these temperature-sensitive products – for brilliant, non-segregating, color-consistent coatings.

- Intelligent process engineering for maximum recipe diversity

- Batch tracking for the most precise product control

- Special explosion protection for maximum safety

- 100 percent control of the bonding process through process technology and automation

- Automatic Tg detection

Battery mass

High-intensity mixers from Zeppelin Systems are ideal for the safe and uniform production of battery compounds using dry and semi-dry processes. High speeds and the special design of the mixing tool and container ensure that the raw materials are mixed and distributed particularly efficiently. Even very fine additives can be dispersed well, binders activated, and the particle structure specifically modified. This increases the bulk density and energy density.

- Production of battery compounds using dry or semi-dry processes

- Individual shear rates, precisely controllable temperature profiles

- Customized wear protection for long service life

- Pre-mixing for fine distribution of additives/conductive additives

Ceramic/metallic feedstock (CIM/MIM)

The conventional process, which involves long kneading and heating times and complex machine technology, is modified so that all components are mixed, homogenized, dispersed, and heated by friction in a single step in the shortest possible time.

- Production of an injectable feedstock in a single process step

- Extremely high homogeneity and thus significant improvement in product properties

- Very short batch times

- Increased productivity

- Lower investment costs than for conventional systems

- Greater flexibility when changing recipes

Benefits

Special highlights

Efficient homogenization & dispersion

High-speed tools (up to 60 m/s) ensure rapid homogenization and powerful dispersion performance—ideal for short processing times and consistent results.

Flexible temperature control

Heating and cooling with a temperature control medium allows the process to be precisely controlled – perfect for plastics, chemicals, minerals, and dyes.

Robust & easy to clean

The low-dead-space design and robust construction enable easy cleaning, long service life, and reliable operation.

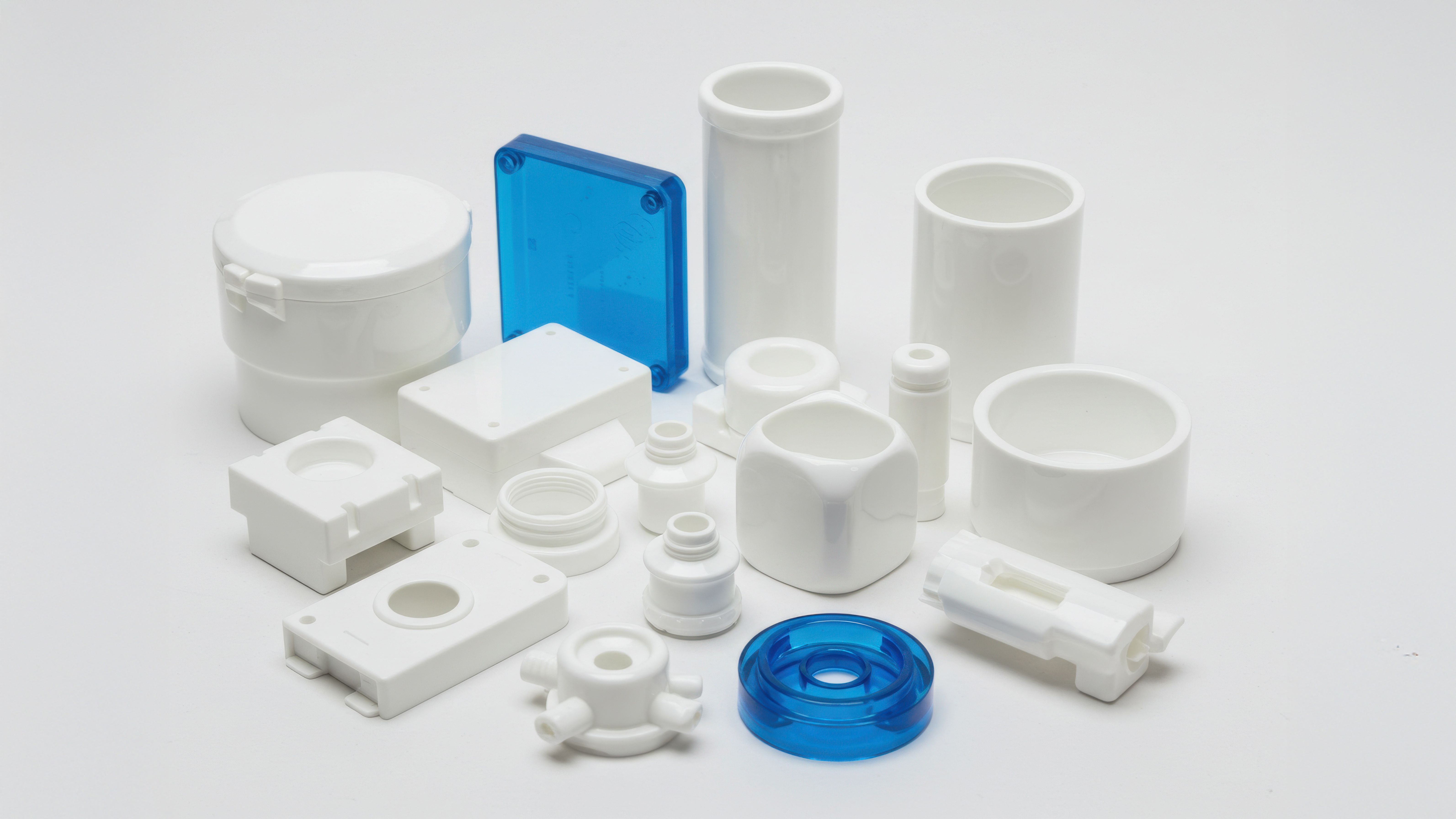

Product details

The high-intensity mixer FM combines advanced mixing technology with a robust, modular design and variable size options. High-quality materials, maintenance-optimized components, integrated control technology, and comprehensive safety features ensure reliable and efficient operation.

Quick and easy cleaning

Self-cleaning effects thanks to flat mixing tools and large bottom bowl radius, as well as improved accessibility for large mixing containers with the optional Transformer package

Robust materials

Various wear protection options for mixing tools and mixing containers

Variable tool setup

Mixing tool with flat tools and large bottom bowl radius for optimal circulation of the mixture without dead spaces

Discharge with optional cleaning package

A swiveling discharge cylinder and inspection flap on the discharge housing facilitate cleaning and save time when changing products

Sizes

We offer our high-intensity mixer type M in various sizes to suit your application.

| Type | Container volume in liters | Working volume in liters | Drive rating (kW), typical/reinforced |

|---|---|---|---|

| FM 75 | 80 | 25–65 | 18.5/22 |

| FM 200 | 240 | 70–200 | 45/55 |

| FM 350 | 380 | 110–320 | 90/110 |

| FM 500 | 570 | 170–480 | 110/132 |

| FM 600 | 670 | 200–560 | 132/160 |

| FM 800 | 920 | 270–780 | 160/200 |

| FM 1000 | 1140 | 340–970 | 200/250 |

| FM 1200 | 1390 | 420–1190 | 250/315 |

| FM 1500 | 1580 | 470–1340 | 315/355 |

| FM 2000 | 2140 | 640–1810 | 450/500 |

Accessories and options

Perfect additions for the high-intensity mixer FM

We offer a range of accessories and options for seamless integration and flexible use of our high-intensity mixers. These include:

Mixer aspiration Vent tec

Highly effective aspiration and filter system for efficient and rapid dehumidification of the mixture during the mixing process. Indispensable for hot mixing processes in PVC processing and in the processing of natural fiber compounds such as WPC, PPC, etc.

Liquid addition

Liquid addition lance in the container wall or lid for adding liquid recipe components during the mixing process – without dripping.

Nitrogen inerting and residual oxygen measurement

In the case of particularly flammable substances, an explosive atmosphere is reliably prevented by inerting with an inert gas and continuously monitoring the residual oxygen in the mixing chamber.

Upgrade to a heating/cooling mixer combination

The heated mix is quickly and effectively cooled using a downstream cooling mixer to make it stable, storable, and easier to process for downstream processes.

Need more details? Our contact person will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Resources

Brochures for Download

Explore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH