Liquids Dosing Cylinder LDC

Optimal temperature and reliable dosing

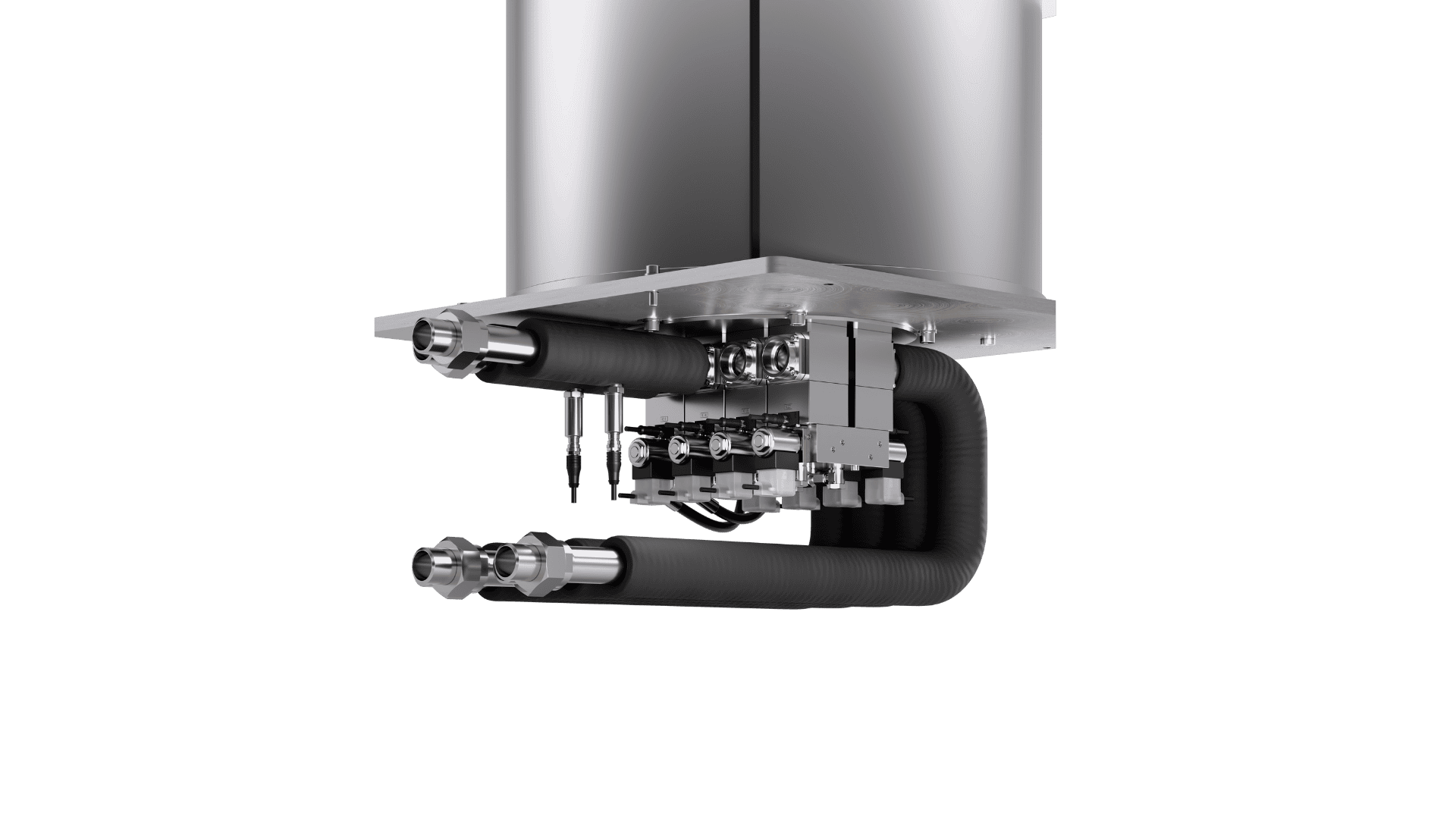

The Liquid Dosing Cylinder (LDC) is the heart of the Liquid Dosing System (LDS). The LDC is used in mixing processes for rubber production. It performs volumetric dosing, conveying, and injection of liquid media. Typical media include oils, silanes, antioxidants, liquid rubbers, resins, solvents, and accelerators. The LDC receives these liquids from several container stations, for example. During operation, both the individual media inlet temperatures and the cylinder temperature, as well as the pressure inside the dosing cylinder, are monitored and controlled. The cylinder doses the target quantity of a liquid according to the recipe and then injects it into the mixer via a position-monitored injection valve at a pressure of up to 40 bar.

Powerful and reliable liquid dosing for your application

With an LDC, up to four different liquid media can be injected with gram-level precision into a rubber mixer via a single injection line and an injection valve within a closed dosing system. The LDC thus ensures safe and automatic batch dosing. The dosing cylinder stands out for:

- a fully automated dosing system

- its high dosing accuracy enabled by a high-resolution position measuring system and temperature and pressure monitoring

- its modular and compact design

- optimized footprint

Product advantages

High dosing accuracy

The dosing cylinder features an automatic dosing system for precise, reproducible material delivery. A high-resolution position measuring system, combined with temperature and pressure sensors ensures stable operating conditions and consistently high dosing quality.

Flexibility

The modular, compact design allows for flexible adaption and quick and easy, fast installation. Reduced overall height and optimized footprint enable efficient integration even in confined installation spaces.

Safety

The closed dosing system operates fully automatically and therefore operator-free, ensuring a clean, safe, and particularly efficient dosing process.

Serviceability

The compact design supports use in limited spaces, while easy installation and integration facilitate rapid commissioning in existing systems.

Flexible application thanks to a wide range of options

The LDC dosing cylinder is available in three sizes (30, 60, or 90 liters). Additional variants are offered, such as cylinders without heating and enclosure or equipped with a position sensor. Up to four media connections can be integrated. The control cabinet can be swiveled and fixed at 90 degrees. Further decentralized peripheral equipment is also available.

Advantages

Special highlights

Batches/hour Dosing capacity

Dosing time

Injection time

Processes and applications

Safer, cleaner, and more precise

The LDC is mainly used in mixers in the rubber and plastics industry, where it is responsible for the volumetric dosing, conveying, and injection of liquid media. Typical media include oils, silanes, antioxidants, liquid rubber, resins, solvents, and accelerators.

Key facts at a glance

We are redefining precision

With the LDC dosing cylinder from Zeppelin, you work not only with exceptional accurately but also with speed. It is part of the Liquid Dosing System (LDS), which enables precise dosing of up to 24 or 36 different liquids. This guarantees maximum dosing and weighing quality for your recipe, along with full traceability of all raw materials used.

Sizes

30 l, 60 l, 90 l

Area of application

Dosing of process oils and plasticizers into powder mixers for the rubber and plastics industry. Suitable for silanes, resins, process oils such as TDAE, RAE, MES, naphthenic, rapeseed or recycled, solvents and highly viscous liquid rubbers, for viscosities up to 7000 mPas.

Pressure range

40 bar injection pressure

Temperature range

Ambient +5 °C / + 40 °C, media +20 °C / +90 °C

Engine

Hydraulic unit with 120 bar

Advantages for the industry

Rubber & Tire

As recognized process experts, we know every step of the rubber and tire industry in detail. Our well-thought-out solutions provide you with measurable advantages across the entire value chain, including the recycling of end-of-life tires.

Go to rubber & tire industryNeed more details? Our contact person will be happy to assist you

Our Customer Services for You at a Glance

Show all Customer ServicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH