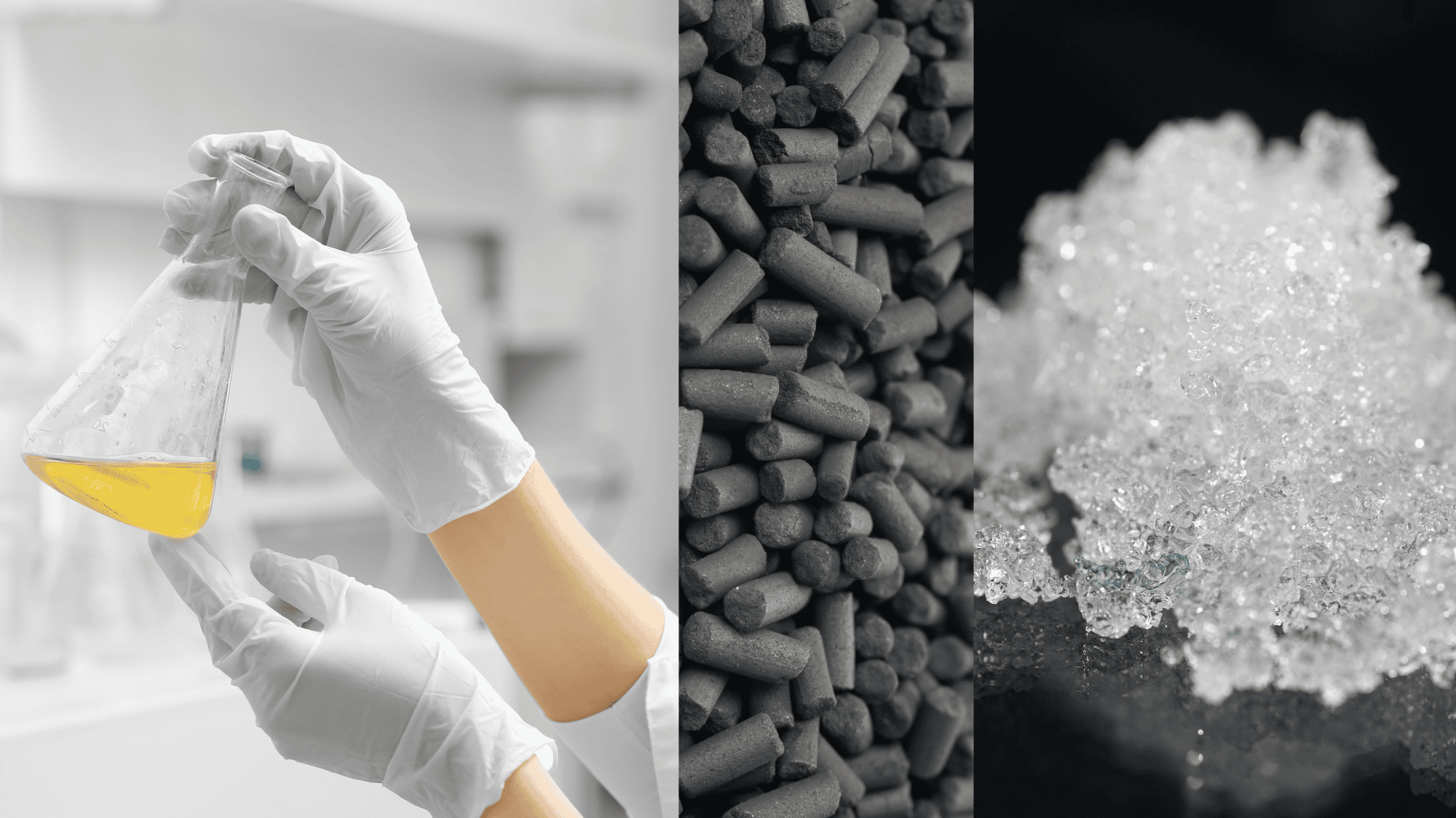

Intelligent plant concepts for specialty chemicals

We develop safety and explosion protection concepts for the safe, dust-free handling of hazardous raw materials - with gentle product conveying, high dosing accuracy and reliable operation even with explosive substances, e.g. due to nitrogen blanketing.

The name says it all

Small volumes, big impact

Although the quantities of specialty chemicals are often not large, their importance for the function of a product is all the greater. Typical examples are flame retardants, active materials for batteries, light stabilizers to prevent the ageing of plastics and paints or additives in food, such as citric acid.

The handling of fine/specialty chemicals requires special know-how, for example with regard to explosion protection, exceptional purity, gentle product handling or possible health hazards for operating personnel.

Zeppelin Systems offers customized system concepts for conveying a wide range of raw materials safely and gently and feeding them precisely into the respective process. We supply solutions for the entire processing chain - from reception, storage and conveying through to precise dosing.

Particular attention is paid to dust-free operation, which is ensured by appropriate measures. For particularly explosive products, nitrogen blanketing is used to prevent the product from coming into contact with oxygen. Our systems are ATEX-certified and meet the highest safety standards. Depending on the location and country, specific regulations apply, which we naturally take into account and integrate into our processes.

In this way, we guarantee not only safety and efficiency, but also the highest product quality.

Application areas

Crop protection and fertilizers

Minerals

Adhesives and resins

Acids (e.g., silicic acid, adipic acid, citric acid)

Specialty chemicals

Additives

Process solutions for specialty and fine chemicals

Filter effectively

Whether from sacks, big bags or octabins: To ensure that the raw materials are fed in as dust-free as possible, we at Zeppelin Systems rely on our self-developed dedusting systems or work together with well-known filter manufacturers. This enables us to respond precisely to your requirements and always select the right product. For example, our jet filters with automatic cleaning prevent unwanted material loss by returning the filter contents to the process and making frequent filter changes superfluous. This saves you maintenance costs and reduces product waste.

In addition, our safe change concepts guarantee that the operator does not come into contact with toxic and respirable raw materials.

Precisely tailored support

We analyze the bulk material properties of your products and develop the optimum conveying process for your individual requirements.

Our technologies are perfectly tailored to your application, whether air conveying in pressure or suction mode, secondary air conveying or dense phase conveying. Of course, your requirements also determine the choice of material: In addition to metal conveyor lines, we can also supply rubber lines for the safe conveying of products that can adhere to metallic surfaces. Conveying abrasive raw materials is also possible with the right choice of material.

The Zeppelin Systems vacuum conveying unit has been specially designed for the precise conveying of powders and granulates with powder content. Due to the large filter surfaces with good cleaning, powdery products are conveyed particularly efficiently. The device offers reliable vacuum conveying, is available in different conveying capacities and batch sizes and impresses with its compact design. It can be used both as a stand-alone device and in collective feeding systems.

Customized storage and discharge solutions

Zeppelin Systems provides end-to-end raw material logistics—from sacks and big bags to full truck unloading—always tailored to the specific properties of the materials, including abrasive or hazardous characteristics. Carefully aligned containment concepts, matched to the respective hazard classifications and OEB levels, ensure that employees and the environment are not unnecessarily exposed to potentially toxic raw or intermediate products.

Naturally, explosion protection and ATEX requirements are also taken into account, with features such as inert gas blanketing integrated into the system. For fast, efficient discharge without bridging, sticking, or material residue, you can rely on our rotary airlocks.

In short: We specialize in handling fine powders (< 50 µm), challenging additives, and powders that must be conveyed using dry air or nitrogen—with safety, precision, and process reliability as top priorities.

Processing for high-quality products

Sometimes more is more! That’s why we refine your bulk materials in mixing and homogenizing silos—either as new installations or as retrofits for existing silos.

Depending on the required product characteristics and mixing quality, we employ a variety of silo types tailored to your needs. These systems are perfectly suited for both free-flowing and poorly flowing bulk materials such as powders, granulates, recyclates, dryblends, or compounds—ensuring optimal homogeneity and consistent product performance.

Precise dosing and weighing

No tolerance for tolerances! Staying true to this principle, Zeppelin Systems has developed ultra-precise weighing and dosing systems for all formulation components—from the smallest gram-range quantities to bulk volumes in the ton range.

Depending on your needs, we offer fully automated systems for small components or high-performance weighing systems for dosing difficult-to-handle powdered raw materials. By incorporating a separate material-specific weighing process, our solutions ensure extremely low tolerances—with each raw material dosed with maximum precision.

Tailor-made mixing solutions

Zeppelin Systems has been setting standards in mixing technology with its HENSCHEL and MTI brand mixers since 1956. Whether in the plastics, chemical, paint and coatings or food industries - with our expertise in mixing, we offer you the solution for your mixing task, for the process, handling and processing. Within the overall process solution, the mixers stand for first-class technical solutions and optimum quality for the end product. The Zeppelin Systems product portfolio includes perfectly matched intensive mixers, cooling mixers and heating/cooling mixer combinations as well as universal mixers and container mixers - adapted to your specific process. Our mixers stand for maximum specific throughput, outstanding reliability and unsurpassed service life. Manufacturing with high precision and using high-quality materials is a matter of course for us. The container mixers and extensive cleaning options for the intensive mixers offer unique possibilities for extremely fast and residue-free cleaning and quick material changes. Our mixers comply with international standards and optional explosion protection ensures maximum safety.

Need more details? Our contact person will be happy to assist you

Services

Discover our comprehensive range of services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs — and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutions

Service

Service without compromise

In the 21st century, optimization often means automation. We ensure that your automation project is a complete success in terms of both efficiency and cost-effectiveness. To achieve this, we rely on cutting-edge control systems whose open architectures prepare you for the challenges of tomorrow—and beyond.

Go to servicesExplore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH