ENTEX Rust & Mitschke GmbH is the leading manufacturer of planetary roller extruders. The process developed by the company enables sulfur compounds to be broken down under specific pressure and temperature conditions. These optimized conditions significantly prevent the rubber's carbon chains from degrading during the process. The devulcanized rubber can be reused to produce new tires. The process is not only simple and cost-effective, it also does not require the use of any chemical additives.

ZEPPELIN SUSTAINABLE TIRE ALLIANCE

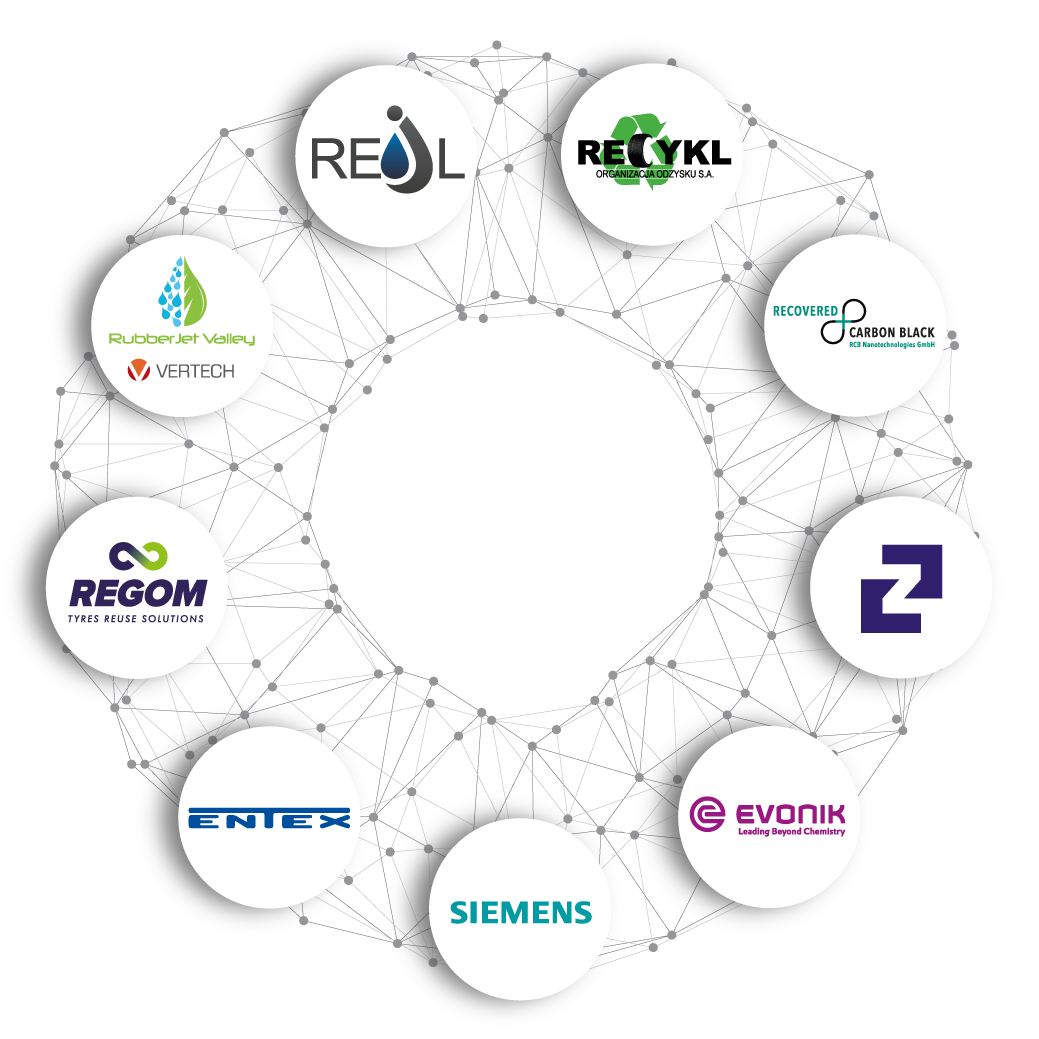

A Strong International Techology Alliance

In times of increasing environmental pollution, high energy prices and resource scarcity, it is more important than ever to use the available raw materials sustainably and reuse them multiple times during the economic cycle. A key role is played by state-of-the-art production processes for both making new tires and, in particular, recycling old tires. In 2023, international companies that are active within the tire production and recycling value chain joined forces to form the Zeppelin Sustainable Tire Alliance (ZSTA). Together, they are driving forward innovative technologies that make tire production and recycling even more sustainable and efficient.

Strong Partners

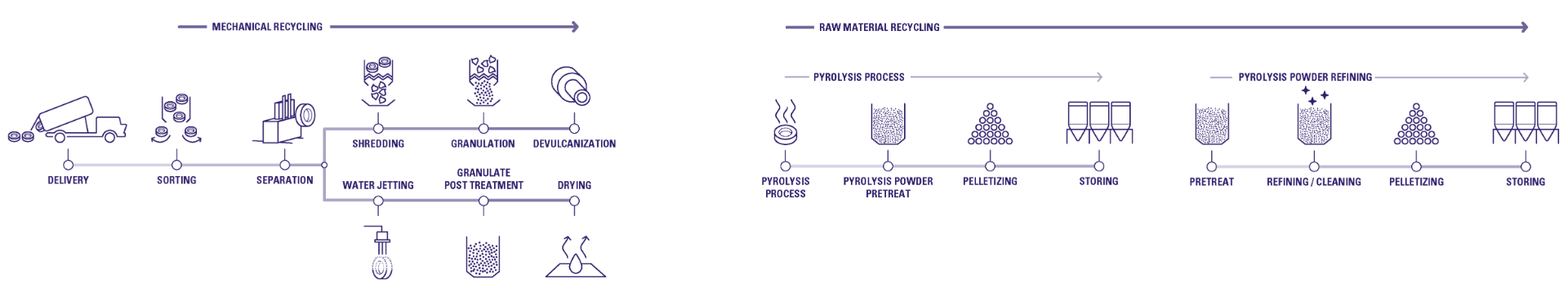

The individual partners are innovative specialists in their respective fields and offer tailor-made solutions for end customers. Zeppelin Systems contributes its expertise in holistically integrating various technologies and processes and thus serves as a bridge builder and system integrator in the tire-to-tire production cycle. The technologies and processes offered include mechanical and raw material recovery with the claim to produce recyclates, for example, which are then used to manufacture new tires as well as many other goods. Some of the technologies can also be integrated into existing systems or retrofitted.

Together with the strong partners of the Zeppelin Sustainable Tire Alliance, we are the ideal solution provider and best system integrator in the industry for (sustainable) tire production.

ENTEX Rust & Mitschke GmbH

Simple and cost-effective devulcanization of rubber with a planetary roller extruder

Evonik Industries AG

With POLYVEST® ST for sustainable improvement of tire properties

The German chemical company Evonik has developed POLYVEST® ST, a liquid additive that tire manufacturers can combine very well with (recycled) rubber and use to optimize the silica/silane system. As a result, the tires have better performance characteristics: improved wet grip and abrasion resistance, which lead to lower particulate emissions, lower rolling resistance and therefore reduced fuel consumption. This reduces climate-damaging CO2 emissions.

RCB Nanotechnologies GmbH

Finishing of raw recovered carbon black

The German company RCB Nanotechnologies GmbH has developed a cleaning process that refines the carbon-containing residual material, the raw-recovered carbon black (rCB), produced during the thermal pyrolysis of old tires. In addition to carbon black, the residual material also contains up to 25% ash, which mainly consists of silicates and zinc. The new technology makes it possible to separate the ash content from the rCB. This means that 100% of the rCB can be used as a raw material. New, high-quality zinc or silicon-based products can also be obtained from the separated ash content. This makes it possible to close further material cycles in the tire industry for the first time.

Recykl Organizacja Odzysku S.A.

Old tires supply textile fibers as stabilizers for asphalt mixtures

The Polish company Recykl Organizacja Odzysku S.A., a member of the Recykl Group (GRC), has been intensively involved in processing used tires since 2004. In mechanical recycling, it has developed new processes – particularly in the devulcanization of rubber – which produce high-quality recycled materials that can be directly incorporated back into the production cycle of new tires by the customer.

REGOM Machinery

Sorting old tires with the help of artificial intelligence

The French company REGOM specializes in sorting end-of-life tires using artificial intelligence (AI). It can read the tire sidewall in a matter of seconds, enabling a highly accurate detection rate of the make, model and size of the tire, as well as the degree of tire wear. This data determines the further use of the old tire: if the condition permits, it is reconditioned and returned to the market. Otherwise, it is separated and shredded. Due to the high degree of precision in the sorting process, the quality of the resulting recyclates can be increased in terms of their purity.

Reoil Sp. z o.o.

Pyrolysis specialist

The Polish company ReOil, Europe's largest pyrolysis plant operator, is active in the field of raw material recycling. ReOil uses continuous pyrolysis to break down rubber from used tires into the substances gas, oil and recovered carbon black (rCB). The recycled materials obtained are reused, for example, in the manufacture of textiles, new tires, rubber components, plastics, steel or aviation fuel. Following the commissioning of the first plant in 2015, ReOil is now recycling around 20,000 tons of used tires per year; construction of a second plant is scheduled to begin in 2024 (engineering and execution are the responsibility of Zeppelin Systems), which will increase annual capacity to around 60,000 tons.

RubberJet Group

Breaking down old tires using a 100% environmentally-friendly high-pressure water jet process

The Italian technology group RubberJet and Vertech specializes in remanufacturing particularly large old tires, for example from trucks, construction or mining machinery. The company developed an environmentally-friendly, patented high-pressure water jet process that separates particularly large tires into individual parts of rubber and steel. The high natural rubber content of large tire rubber compounds means that the recyclates obtained are of particularly high quality. In addition, this recycling process gives them a particularly large surface structure, which is indispensable for re-cross-linking so that the recycled material can be vulcanized again in new tire or rubber compounds. These quality advantages allow the rubber flour and granules obtained in this way to be marketed directly.

Siemens AG

Technological innovation driver for automation and digitization

All production and recycling processes, including the entire supply chain, form a unit that must be considered holistically in its processes. Siemens AG supports the industry with automation and digitization processes. As part of the Zeppelin Sustainable Tire Alliance, Siemens provides the use of digital twins to develop and improve sustainable tire production. These make it possible to simulate seamless information flows between the real and digital worlds for example, as well as to model holistic sustainability effects along the value chain, and the optimization of process cycles. This partnership also includes driving decarbonization through transparent and manageable product carbon footprints (PCFs) with SiGreen, a SaaS application for exchanging dynamic PCFs along the Siemens value chain.