Mixing Silos from Zeppelin Systems

Maximum Mixing Performance and Product Quality

Mixing and Storing Made Easy for Any Bulk Material

In the production or recycling of plastics, maintaining consistently high product quality can be challenging due to process or raw material fluctuations. This is where gravity mixers make a decisive difference, significantly improving the quality of the final product. Our gravity mixers handle large product volumes with minimal recirculation, producing highly homogeneous mixtures without additional energy input. This not only saves time and energy but also reduces dust generation. Our mixing silos are recognized by all major licensors in the plastics processing industry.

Advantages of Zeppelin Systems Mixing Silos

- Homogenization of Process or Raw Material Fluctuations

- Reliable Mixing for Powders, Pellets, and Flakes

- Solutions for Poorly Flowing and Extremely Lightweight Products

- Extensive Cleaning Accessories

- Retrofit Concepts

- Odor Neutralization and Deodorization (Degassing)

- Mixing Tests in Our Own Technology Center and Laboratory

The Mixing Silos from Zeppelin Systems

Multichannel Mixing Silo

The bulk material is discharged simultaneously from 18 different levels via vertically arranged mixing pipes in the mixing silo, directed into the mixing chamber, blended, and then discharged. As a result, the product at the mixer outlet represents a homogeneous mixture from the entire silo. Multi-channel silos are suitable for free-flowing bulk materials such as plastic granules and can accommodate capacities of up to 3,000 m³. They are suitable for both continuous and batch mixing processes.

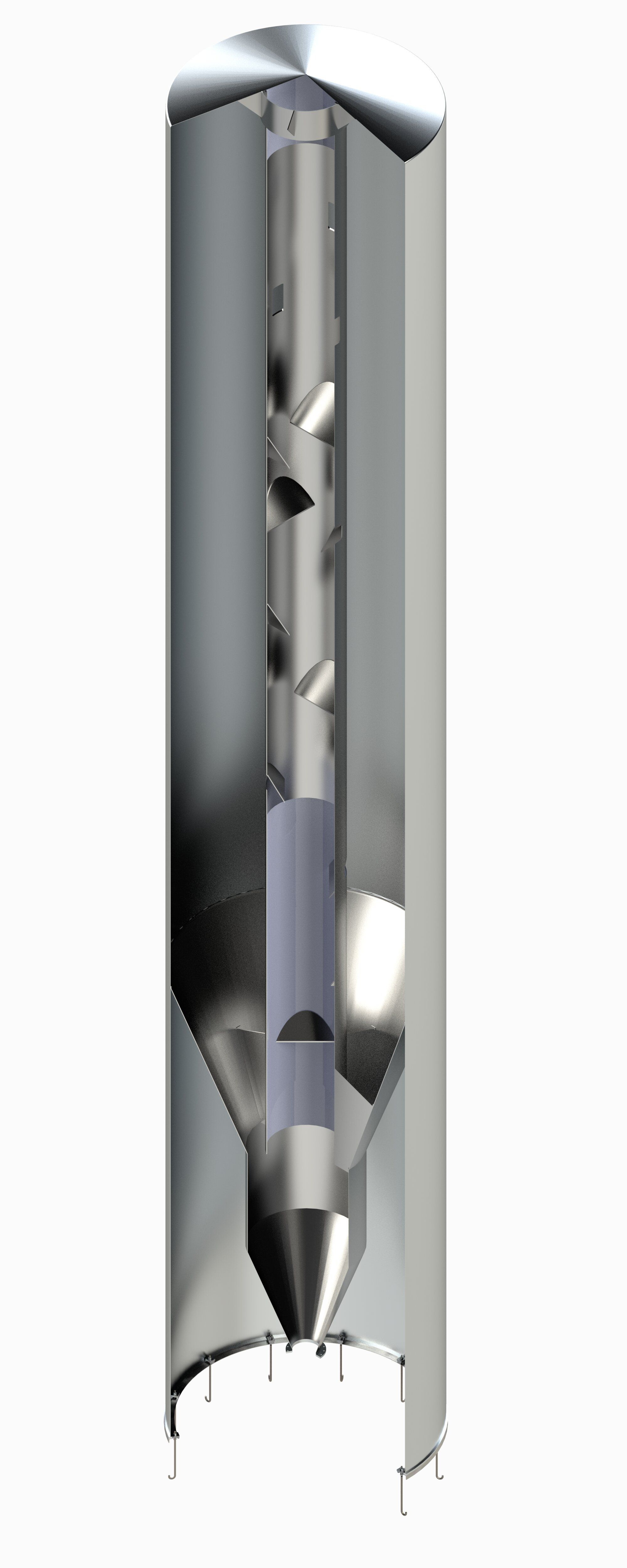

Centro-Blend Mixing Silo

The bulk material is simultaneously discharged from the central pipe through inlet openings at various levels and directed into the mixing chamber. To ensure equal withdrawal from all layers, baffle plates of varying sizes are welded above the inlet openings. The product from the mixing pipe is blended in the mixing chamber with the product from the annular space.

Centro-Blend mixing silos are suitable for both free-flowing and poorly flowing bulk materials such as plastic powders, recycled materials, granulates, and free-flowing elastomers. They are used in both continuous and batch mixing processes. Standard capacities range from 7 to 300 m³.

Multi-Flow Mixing Silo

The Zeppelin Systems Multi-Flow mixing hopper creates different flow velocities within the hopper and the cylindrical lower mixing section. This results in varying residence times, which generate the mixing effect. Multi-Flow mixing silos are particularly efficient with a slenderness ratio (height to diameter) of less than 2.5.

Multi-Flow mixing hoppers can be welded into new silos or retrofitted to existing silos by flanging or welding. They are suitable for both free-flowing and poorly flowing bulk materials such as pellets, powders, dry blends, compounds, or recycled materials and can be used for both continuous and batch mixing processes.

Fluidized Bed Mixing Silo

Fluidized Bed Mixing Silo

Fluidized bed mixing silos are suitable for mixing fluidizable bulk materials with particle sizes below 500 μm. In this process, the bulk material is aerated and fluidized using a fluidizing gas, typically air. By varying the intensity of aeration across different flow zones, horizontal mixing can be enhanced. This allows for optimized mixing performance and reduced mixing time.

Homogenizing Silo

Pneumatic mixers for gentle homogenization of fluidizable bulk materials

Pneumatic mixers, also referred to as homogenizing silos, are suitable for the gentle mixing of fluidizable bulk materials, baking ingredients, cappuccino blends, and more. The mixer can be used as a standalone unit in either a non-pressurized or pressure-tight design, or integrated into complex systems.

Our Silo Designs

Bolt-Tec – Rethinking Smart Storage

Panel-Tec – High Volume Meets Maximum Efficiency

Weld-Tec – A Modern Take on a Classic Storage Concept

Our Advantages for the Industry

Zeppelin Systems is globally recognized by leading licensors and contractors. With our in-house technical center and a specialized laboratory for mixing trials, we offer optimal conditions for the precise design of your processes. Our expertise includes signal response analysis and the development of tailored solutions to meet your specific requirements.

Application Areas

Industries

Need more details? Our contact person will be happy to assist you

Our Customer Services for You at a Glance

Show all Customer ServicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH