Food Industry

Food Technology Center in Rödermark

Your Products Tested: Innovations for the Future with Sustainable Solutions

The Food Technology Center in Rödermark has been specifically designed to meet the requirements of the food industry and provides ideal conditions for testing the processing of liquid and powdered raw materials. With an area of over 300 m² and a height of 10 meters, experiments can be conducted not only on a laboratory scale but also with real performance for our customers. This is because, on the two-story test area, no standard systems are permanently installed; instead, a modular system has been developed, ensuring high flexibility.

Do you want to know how the chocolate flakes behave in your new formulation during mixing? Which type of conveying generates the least abrasion with one of your raw materials, or how to keep your agglomerates intact? Then simply use our technology center.

Together with our technology centers in Friedrichshafen and Kassel, we form a network for the handling of high-quality bulk materials. While Friedrichshafen covers the areas of plastics, chemicals, and rubber, the Kassel technology center specializes in mixing and compounding.

PRODUCTS

Custom Tests for Your Products

Bakery Products

Confectionery

Pasta

Pet Food

Dairy Products

Baby Food

Starch/Derivatives

Cereals

Spices

Instant Beverages

Ready-to-Eat Meals

Powdered Sugar

Process Steps

Test Facilities for All Process Steps

Precise Dosing

Accuracy is a critical criterion for the quality of any manufacturing process that uses dosing technology for bulk material control. When it comes to the precise dosing of dry solids and liquids, we offer a selection of suitable methods for the accurate and product-friendly dosing of your formulation:

- Dosing screws, rotary valves, and coke ice for precise scale filling

- Docking of dosing containers at dosing stations for dust-free transfer of batches

- Discharge devices for the safe extraction of bulk materials with problematic flow behavior from silos and scale containers

Fermentation in a Semi-Continuous Process

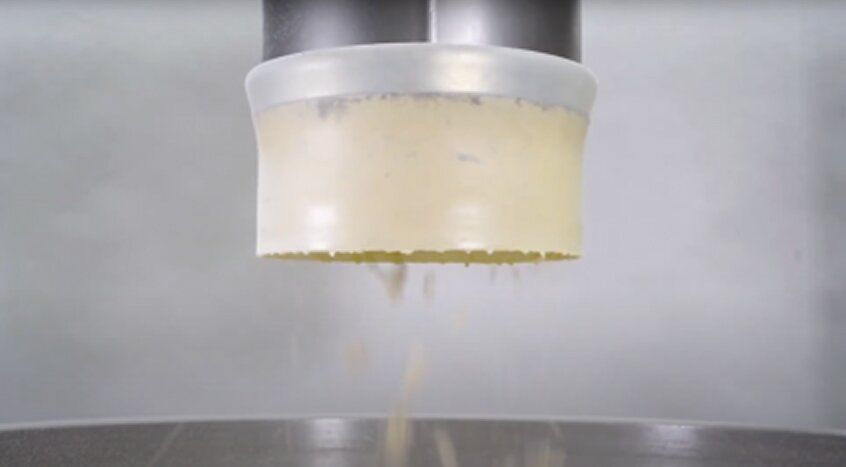

In the modular fermentation process, two process steps are used. The first module is the "DymoMix Tower" for mixing flour and liquids, and the second module consists of fermentation tanks equipped with screw spindle pumps. The modules can be connected in various configurations.

The technology center can simulate a system with a mixing capacity of up to 5 t/h and a double-walled fermentation/storage tank with approximately 1m³ capacity. Depending on the application, wheat pre-ferment/liquid sponge or rye sourdough can be produced on the test system.

This dough can be used either autonomously or as a raw material for our Codos system for continuous dough production. Alternatively, it can also be further processed batch-wise using a batch mixer.

The fermentation process follows the newly developed procedure, is easily reproducible, and works ideally with other components of continuous dough production:

- DymoMix

- Codos kneader

- Reception container

- Differential dosing scale

Uniform Discharge

Zur Austragung schwer fließender Schüttgüter werden produktspezifische Austragsorgane verwendet. WiFor the discharge of poorly flowing bulk materials, product-specific discharge devices are used. We are happy to assist you in selecting the right components, which are optimally matched to your formulations and ensure uniform material flow and precise dosing:

- Discharge devices for the safe extraction of bulk materials with problematic flow behavior from silos and scale containers

- Sack filling station

- Big Bag Station

- Combined sack filling/Big Bag station

- Fluidized bed with air loosening for discharge

- Kokeisl (allows very fast and highly accurate dosing)

- Discharge agitator (screw conveyor or cone mixer)

Gentle conveying

Gentle conveying is crucial for achieving optimal results. For the transport of abrasive or break-sensitive bulk materials, such as agglomerates, our technology center is equipped with various conveying systems:

- Pneumatic conveying (pressure/vacuum): DN 65 – 110/80 – 240 m

- Plug conveying (pressure/vacuum): DN 65 – 110/80 – 240 m

- Secondary air conveying: DN 65 – 125/80 – 160 m

Homogeneous Mixing Results

Efficient production lines with high availability and reproducible product quality can only be realized with optimal system technology and a process designed to meet the specific requirements of each product. To test your perfect mixture, we offer the following options:

- Codos NT: Open, continuously operating horizontal mixer or kneader with two interlocking mixing-kneading tools.

- DymoMix: Uniform wetting of dry materials with liquids as a pre-mixer (dough production) and for moistening dry materials.

- Horizontal Mixer: For mixtures of dry powders or with liquid spraying, up to chocolate mixtures.

- Pneumatic Homogenizing Unit: Gentle homogenization of agglomerates and fine powders in a fluidized bed.

- Screw Conveyor Mixer: Pre-mixer for small footprint and optimal use of height.

- Cone Mixer: For discharging powder mixtures without residues.

Raw Material Preparation and Conditioning

For optimal and, most importantly, reproducible results of the final product, the conditions must remain constant. Therefore, the raw materials used must always be processed under the same conditions. There are three main methods for achieving this:

- Moistening with DymoMix: Dry materials are wetted with liquids in seconds, aerated, and mixed before being introduced into the actual dough production process. This results in doughs that can be used immediately or fed into batch kneading or continuous kneaders.

- Conditioning with PneumoTherm: For optimally conditioned raw materials (heating/cooling), e.g., for flour cooling.

- Classification with Sieving Machines: Protective sieving with inline sieving machines in various sizes and mesh openings.

Comprehensive Analysis Capabilities

Conducting investigations and analyses, which are then discussed with you:

- Viscosity measurements of liquids

- Determination of water activity and moisture content of the product

- Measurement of density or particle size distribution

- Assessment of particle or agglomerate structure and abrasion

- Measurement of rheological dough properties using a Farinograph

- Shear test – shear analysis for silo dimensioning

Need more details? Our contact person will be happy to assist you

Zeppelin Systems Technology Center

Our Technology for Different Industries

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH