Universal Mixers

Maximum efficiency for your mixing processes

Perfect mix. Flexible use

Different products require different raw materials - and each has its own characteristics. Because we know this, we have designed our universal mixers to be flexible: There is a tailor-made solution for every requirement. So that raw materials are always optimally treated. This is how you mix today!

The right universal mixer for your application

- Optimized solution for universal use with different processes

- Application-oriented tool configurations and drive capacities

- Short mixing times with minimal energy consumption and gentle product handling

- Innovative control systems and user-friendly safety technology in accordance with the latest guidelines

- Optional equipment: Double jacket, chopper, spray systems for liquid recipe ingredients, vacuum version, explosion protection, etc

Benefits

Special highlights

Self-cleaning effect due to perfect mixing vortex

The unique flowing motion creates an intensive mixing vortex that not only ensures excellent mixing quality, but also cleans all surfaces that come into contact with the product – ideal for frequent product changes and high hygiene standards.

Dead space-free outlet for almost complete emptying

Maximum product yield without residue: The special outlet minimizes product loss and makes cleaning easier – a real advantage in process optimization.

Available in flexible sizes

The universal mixers can be perfectly adapted to your requirements and offers maximum flexibility for a wide range of applications.

Product details

Different sizes

- 250-8500 l gross volume

- For batch sizes from 40-3600 kg (with a bulk density of 0.6 kg/l)

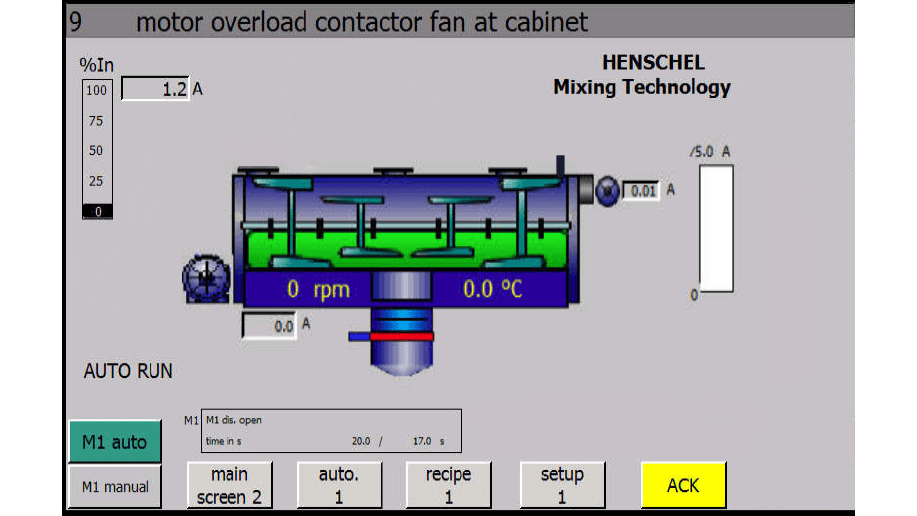

Intuitive mixer controls

- User-friendly operation

- Manual and automatic operation

Maximum productivity

- Process-optimized detailed design

- Use of energy-efficient components

Certified design

- All ATEX designs possible

- CE conformity

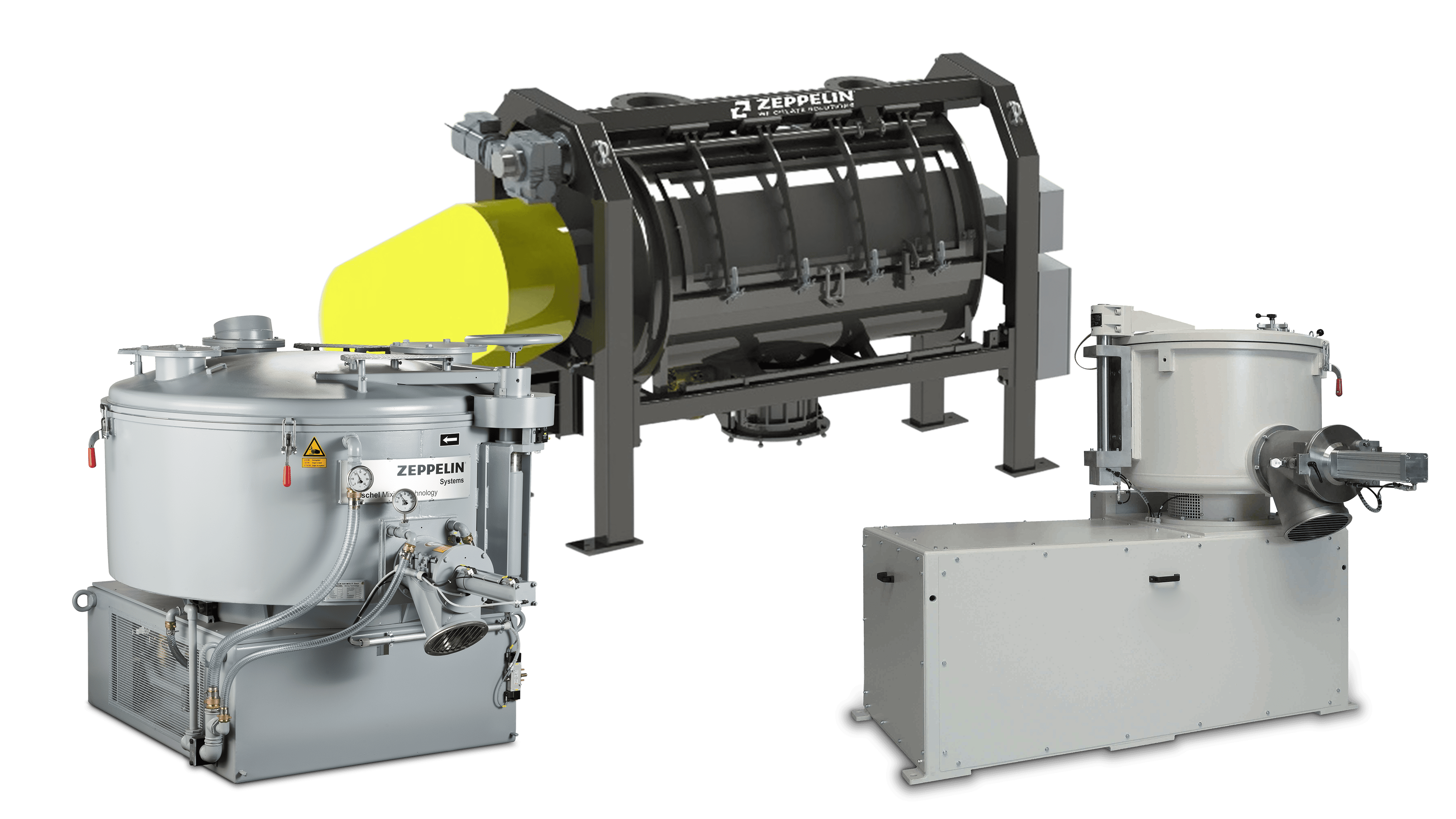

Product types

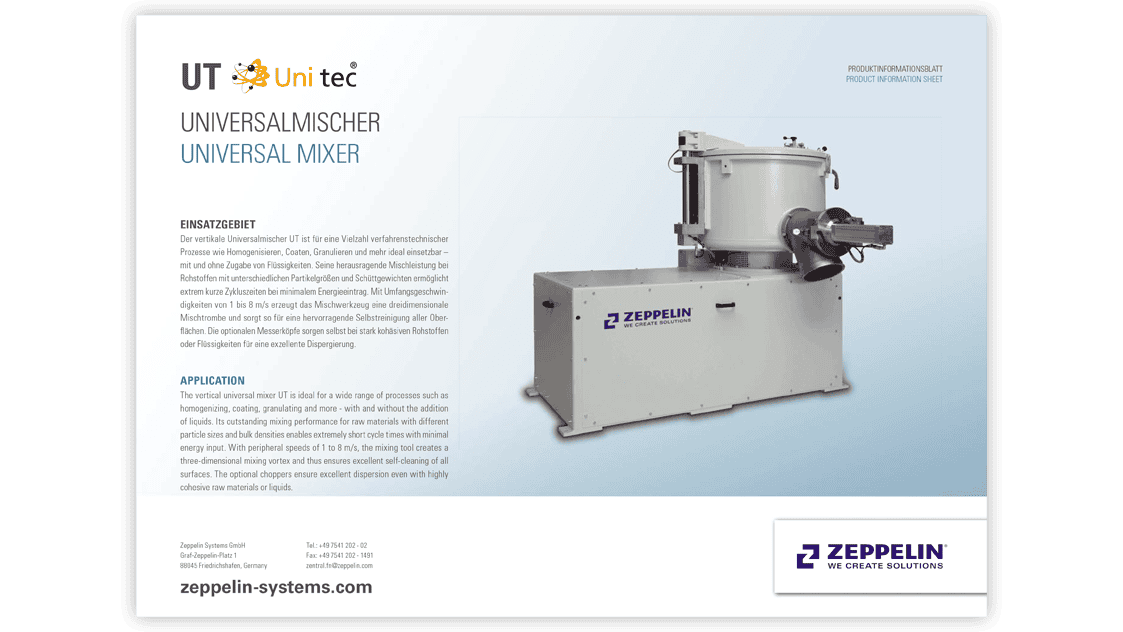

Universal Mixer UT Uni tec

The universal mixer UT delivers reliable, reproducible results for complex mixing processes. The optimized mixing tool ensures intensive, three-dimensional mixing. All parts that come into contact with the product are made of stainless steel. Suitable for a wide variety of bulk materials, including those with added liquids, and optionally with temperature-controlled processing under vacuum.

Universal Mixer KM-HU

The universal mixer KM-HU delivers impressive results in simple mixing tasks with precise results—even when liquids are added. The mixing tool distributes the product gently and thoroughly. Stainless steel parts guarantee quality and hygiene. Suitable for a wide variety of bulk materials.

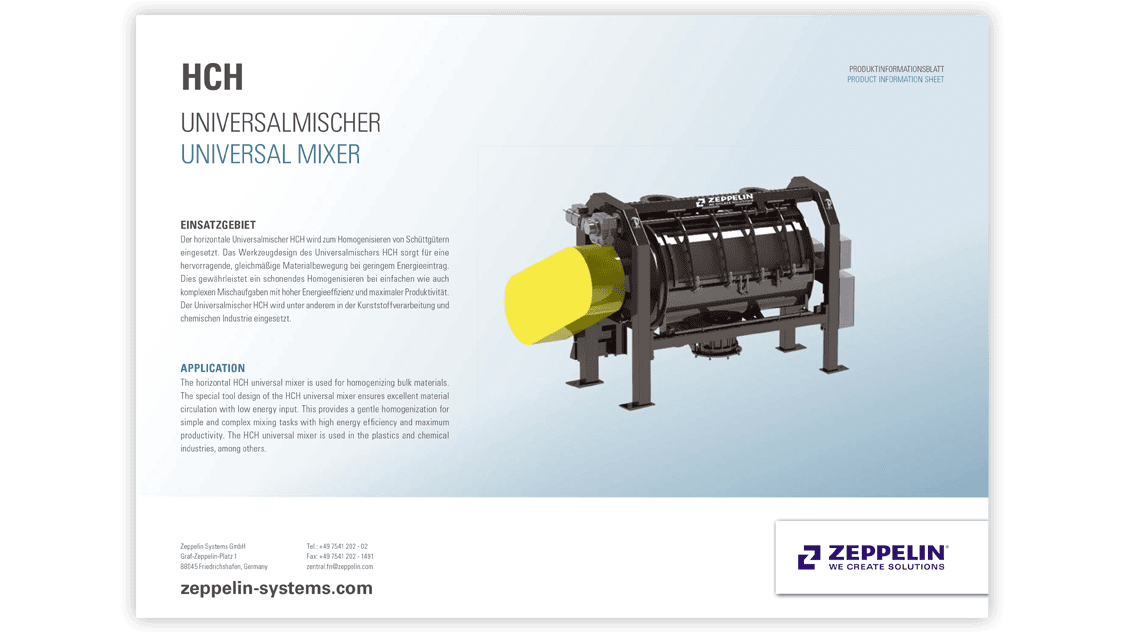

Universal Mixer HCH

The universal mixer HCH delivers reliable results for a wide range of mixing tasks. The tool ensures gentle, intensive mixing. All parts that come into contact with the product are made of stainless steel. Suitable for a wide variety of bulk materials and liquid additives.

Need more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Ressources

Brochures for Download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH