Process Mixer MB

For brilliant powder coatings

Bonding at its best

The production of metallic powder coatings with bonding requires the highest precision. Zeppelin Systems' proven technology and process engineering is recommended for consistently high, stable quality. Precisely defined process control ensures safety, virtually loss-free production, and excellent processing of the mixture.

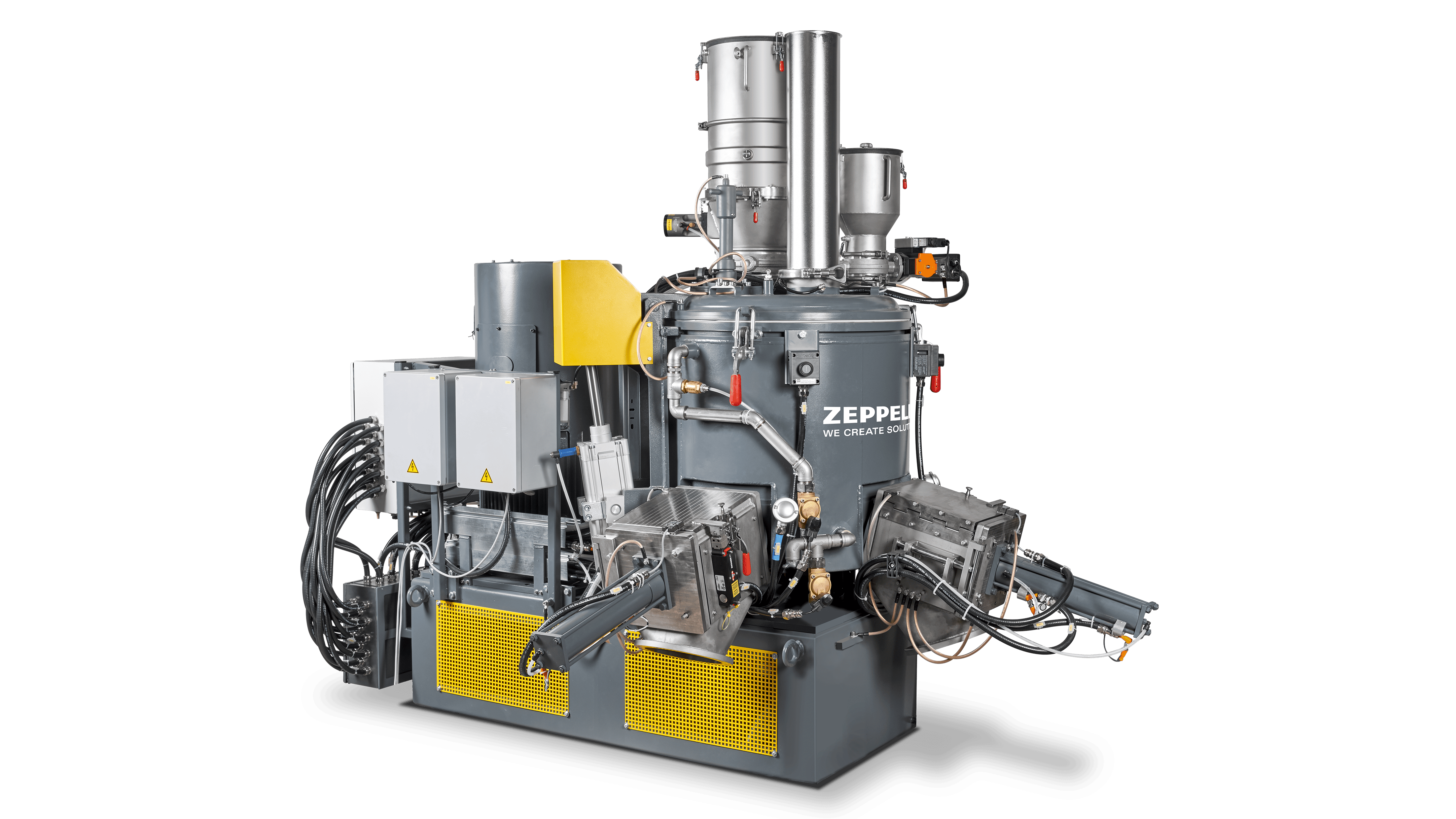

The process mixer MB is a modular heating mixer, ideal for metallic and effect powder coatings. It offers multi-zone temperature control (drive shaft, mixing tool, double jacket, bottom bowl) for precise temperature control. Cooled tools, nitrogen inerting, and residual oxygen measurement are available as options.

Key advantages at a glance:

- No segregation due to complete bonding

- Cooled mixing tool and mixing container

- Fully automatic Tg (glass transition temperature) detection

Application areas

Bonding of powder coatings

We have set new standards in the industry with our perfected bonding process for the production of metallic powder coatings. Our mixers with intelligent control technology offer the ideal solution for the special processes and requirements of these temperature-sensitive products. This allows you to produce brilliant, non-segregating, color-consistent coatings that give you a competitive edge in the international market.

- Intelligent process technology for maximum recipe diversity

- Batch tracking for precise product control

- Special explosion protection for maximum safety

- 100% control of the bonding process through process technology and automation

- Automatic Tg detection

Benefits

Special highlights

Bonding Efficiency

No separation after the process thanks to complete bonding

Process control

Complete tool cooling and multi-zone cooling container

Ease of cleaning

Minimal material adhesion, easy accessibility, split container (optional)

Product details

The process mixer MB from Zeppelin Systems combines innovative process technology with the highest safety and automation standards. Developed for the demanding production of metallic and effect powder coatings, it impresses with reliable bonding results, maximum operational reliability, easy cleaning, and modern, intuitive controls.

Highest and consistent product quality

Complete bonding of the effect pigments to the powder coating for consistently high quality. Flexible in use and suitable for a wide variety of aluminum pigments—from fine to coarse, including silver dollar and cornflake—as well as for mica and other effect pigments.

Safe operation

Aluminum pigments are particularly sensitive to ignition and require special protective measures. The process mixer MB offers maximum safety with nitrogen inerting and permanent oxygen monitoring in the mixing chamber. The system is certified according to ATEX Directive 2014/34/EU and is available in various device categories depending on the application – up to the highest protection class 1D in the mixing chamber.

Quick and easy cleaning

The pneumatic hinged lid and the discharge with cleaning package allow convenient access to the mixing chamber. For larger mixing containers, the optional Transbonder package provides even better accessibility and makes cleaning and maintenance much easier.

Automation

The control system is based on the Siemens TIA Portal and offers an intuitive user interface. With PVS process visualization, process values can be displayed graphically and recipes can be managed efficiently. Functions such as batch tracking, machine operation, and remote maintenance ensure transparent and smooth operation.

Sizes

We offer our process mixer MB in various sizes to suit your application.

| Type | Typical batch size |

|---|---|

| MB 10 | 2–3 kg |

| MB 75 | 20–25 kg |

| MB 200 | 60–80 kg |

| MB 350 | 130–150 kg |

| MB 500 | 180–210 kg |

| MB 600 | 200–250 |

| MB 1000 | 380–420 kg |

Accessories and options

Perfect additions for process mixer MB

We offer various accessories and options for seamless integration and flexible use of our process mixer MB. These include, among others:

Interchangeable containers for pigments

For the automatic addition of effect pigments during the mixing process. With this interchangeable system, filling can take place at a suitable weighing station (different designs possible).

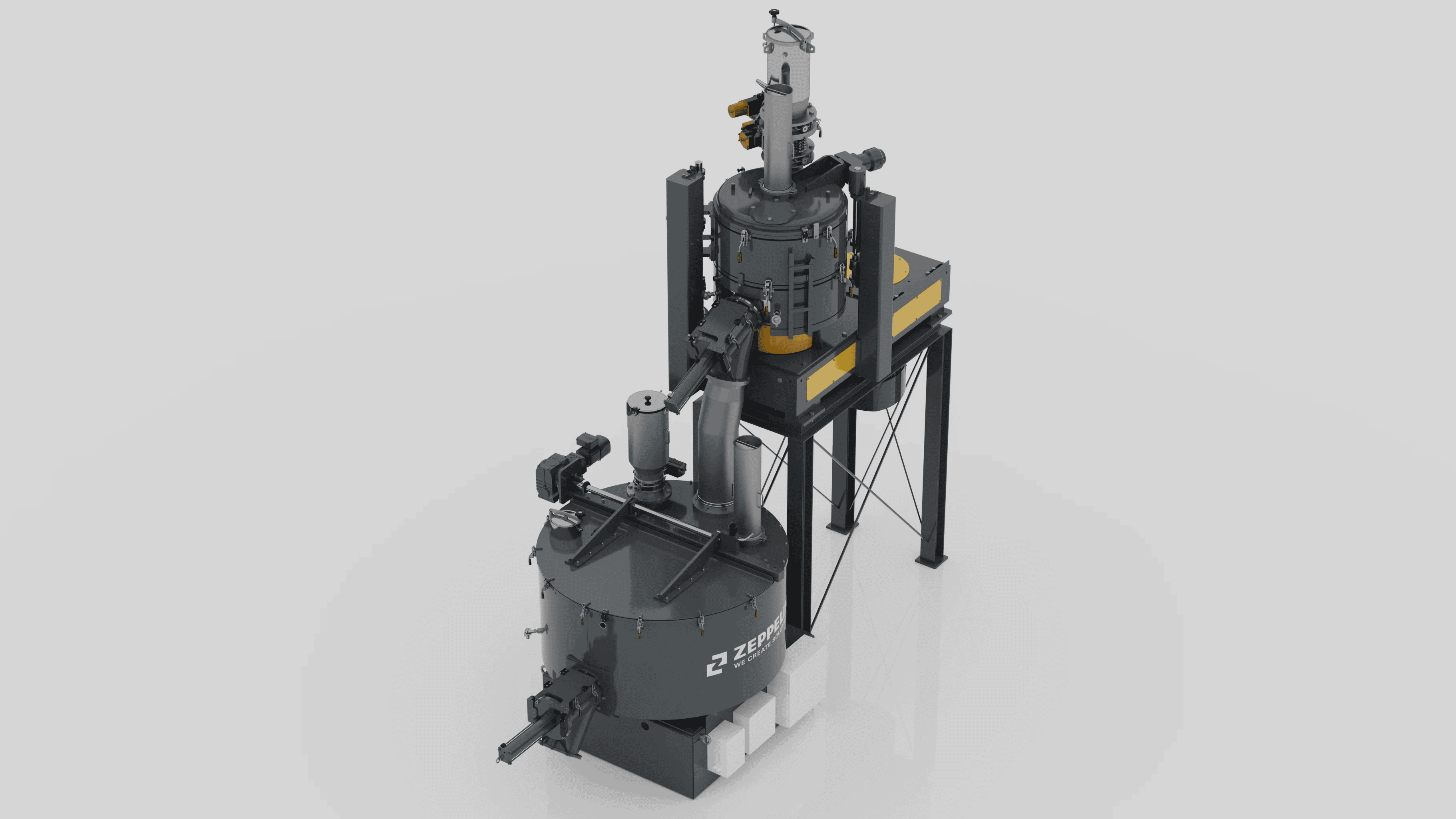

Cooling Mixer KM

To increase throughput to up to four batches/hour: Cooling Mixers Type KM are specially equipped for cooling metallic powder coatings when used in combination with MB mixers. This also includes design and certification in accordance with ATEX with inerting and continuous oxygen measurement.

Need more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH