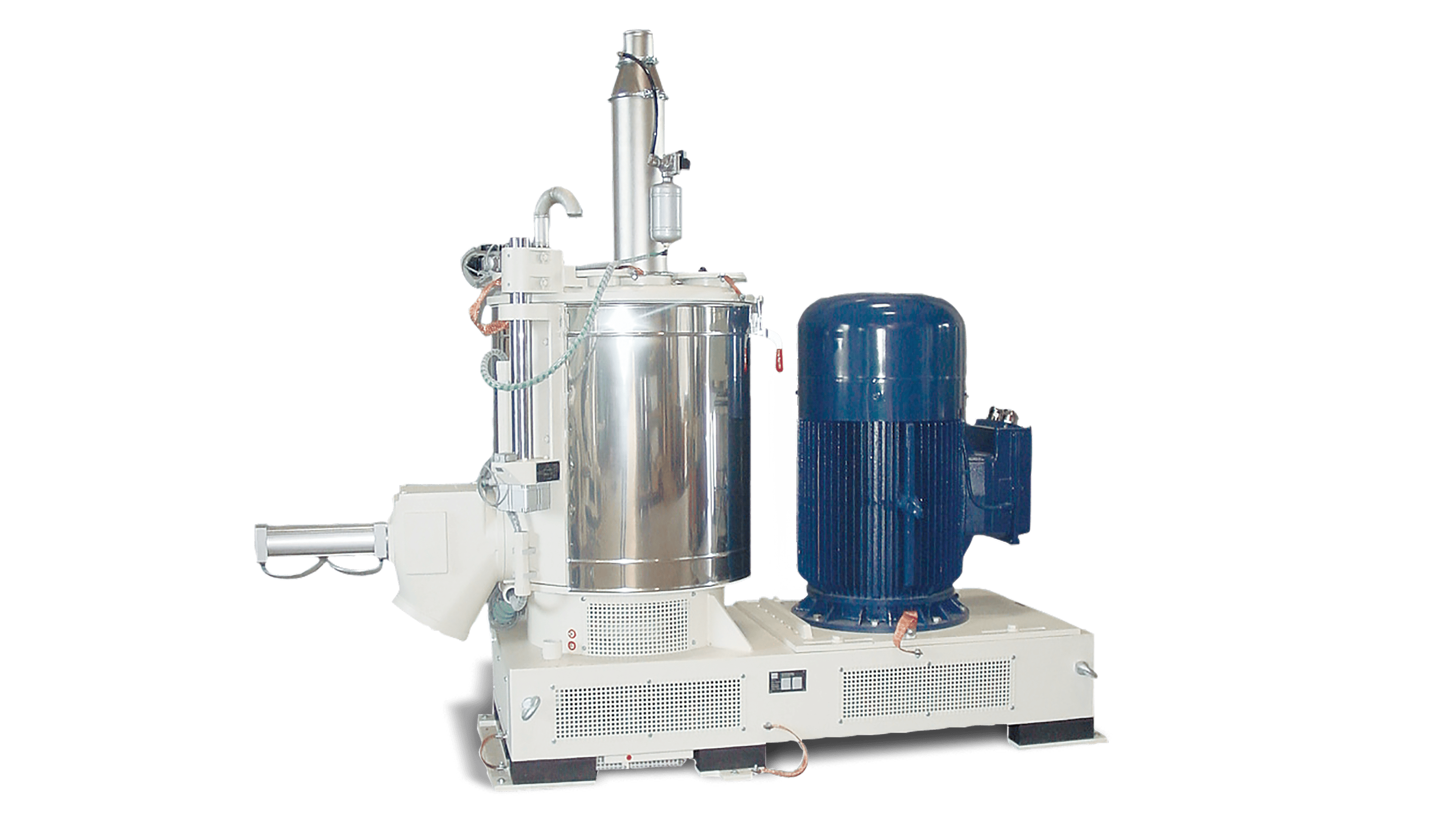

High Intensity Mixer M

For demanding applications

Versatile use with intense mixing performance

The high-intensity mixers type M are ideal for PVC processing and offer optimum friction initiation for fast and gentle dryblend production to meet the highest demands.

The mixing tools, which rotate at speeds of 3 to 30 m/s, create an intensive, three-dimensional mixing effect. At the same time, friction is used to introduce heat into the mix without causing partial overheating. The aim is to generate as much energy as necessary while treating the mix as gently as possible. The modular and individually confi gurable tool design in combination with the extremely long tool shaft allows a highly flexible, adjustable friction input with a perfectly formed mixing vortex.

Key advantages at a glance:

- Gentle product preparation and fast, efficient homogenization of the entire mix with peripheral speeds of up to 30 m/s

- Optimum process control thanks to adjustable mixing tools on a long shaft, individual tool configuration and speed-controlled motor

- Variable heat input by means of friction, very good heating performance with short heat-up times

- Individually configurable for perfect adaptation to the product

- Quick and easy cleaning

Benefits

Special highlights

Flexible filling level

Thanks to the extremely flexible filling level of 25 to 85 % of the gross volume, different batch sizes can be processed with one machine – without compromising on mixing quality.

Self-cleaning effect due to perfect mixing vortex

The self-cleaning effect of all surfaces that come into contact with the product reduces cleaning effort, minimizes downtime and improves hygiene.

Easy accessibility

The fully opening hinged lid facilitates inspection, cleaning and maintenance.

Need more details? Our contact person will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Explore more from the Zeppelin Systems portfolio

Products

© 2025 Zeppelin Systems GmbH