Heating/Cooling Mixer Combinations

Perfectly combined

The right solution for your application

Our heating/cooling mixer combinations meet the highest requirements for mixing quality and can be used for almost any application. The higher the mixing, the better: Zeppelin Systems heating/cooling mixer combinations generate an intensive mixing effect – the basis for high-quality products. And thanks to effective aspiration, they ensure perfect dehumidification of the mix for optimum further processing. Everything for excellent product quality.

Benefit from our individual solutions specially tailored to your application! All high-intensity mixers can be individually combined with horizontal or vertical cooling mixers to create the optimum system for your products.

Heating/Cooling Mixer Combinations for

- PVC dryblend preparation

- Masterbatch compounds

- Single pigment concentrates

- Bonding of metallic powder coatings

- WPC and natural fiber compounds

- Coating of minerals

- Battery compounds

Benefits

Special Highlights

Different sizes

The mixing systems are available in various designs and are suitable for batch sizes from 25 to 1500 kg. This allows a wide range of production requirements to be covered efficiently.

Individual combinations

Depending on your requirements, a horizontal cooling mixer for high throughput or a vertical cooling mixer for particularly easy cleaning can be integrated. The modular solutions are optimally adapted to different applications.

Maximum productivity

Process-optimized designs and the use of energy-efficient components ensure maximum productivity with reduced energy consumption.

Typical Heating/Cooling Mixer Combinations

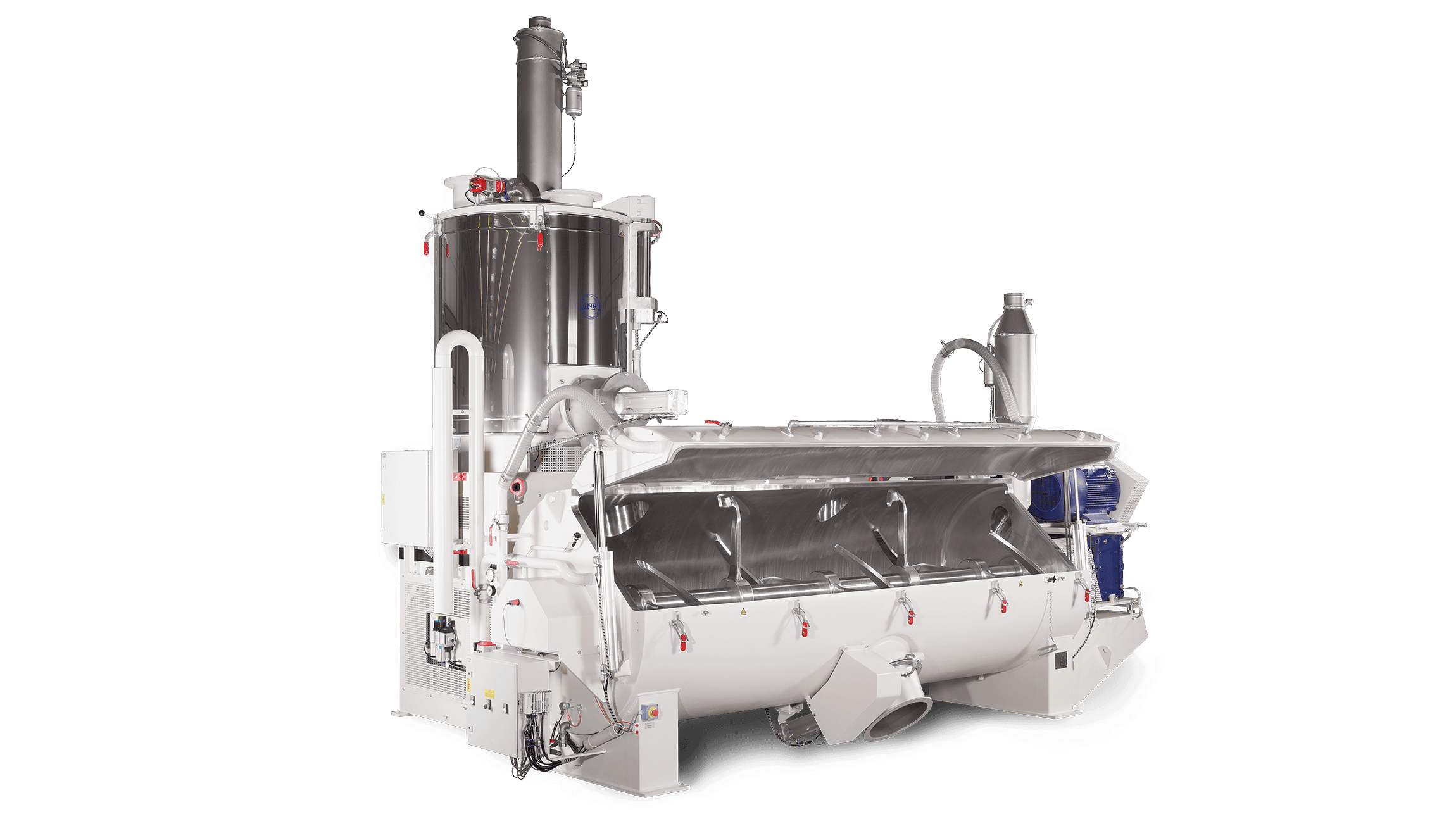

Heating/Cooling Mixer Combination MTI Flex-line

The ideal heating/cooling mixer combination for PVC dryblend processing. It consists of a high-intensity mixer type M with perfect friction initiation for fast and gentle dryblend production for the highest demands and a horizontal cooling mixer type K for maximum cooling capacity.

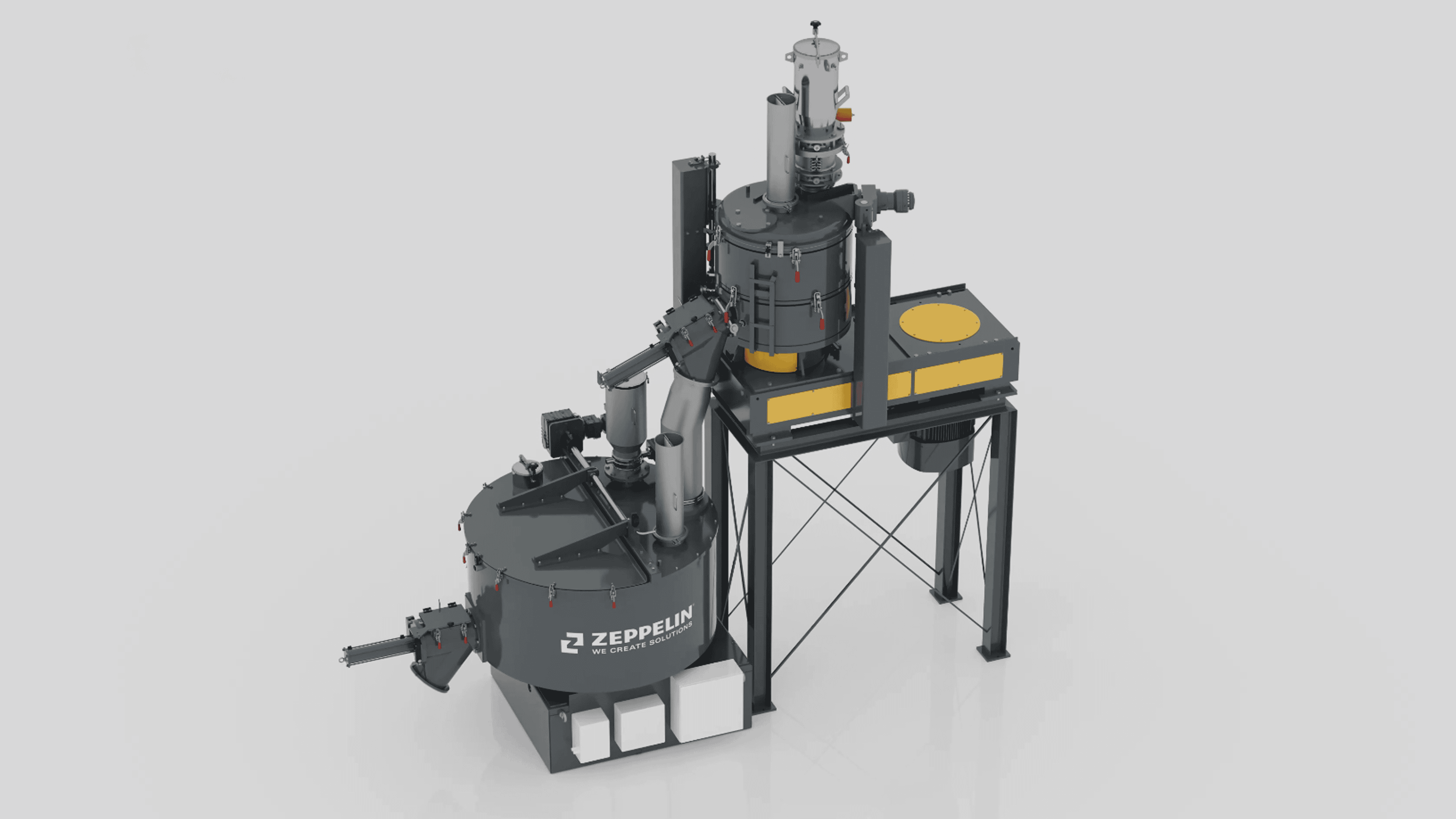

Heating/Cooling Mixer Combination MB-KM "Bonding"

The world's most precise, gentle and reliable system for the bonding process in the production of metallic powder coatings. It consists of a process mixer type MB with absolute process reliability – no other mixer moves so close to the glass transition temperature – and a vertical cooling mixer type KM for faster cooling after bonding and for the best possible cleaning.

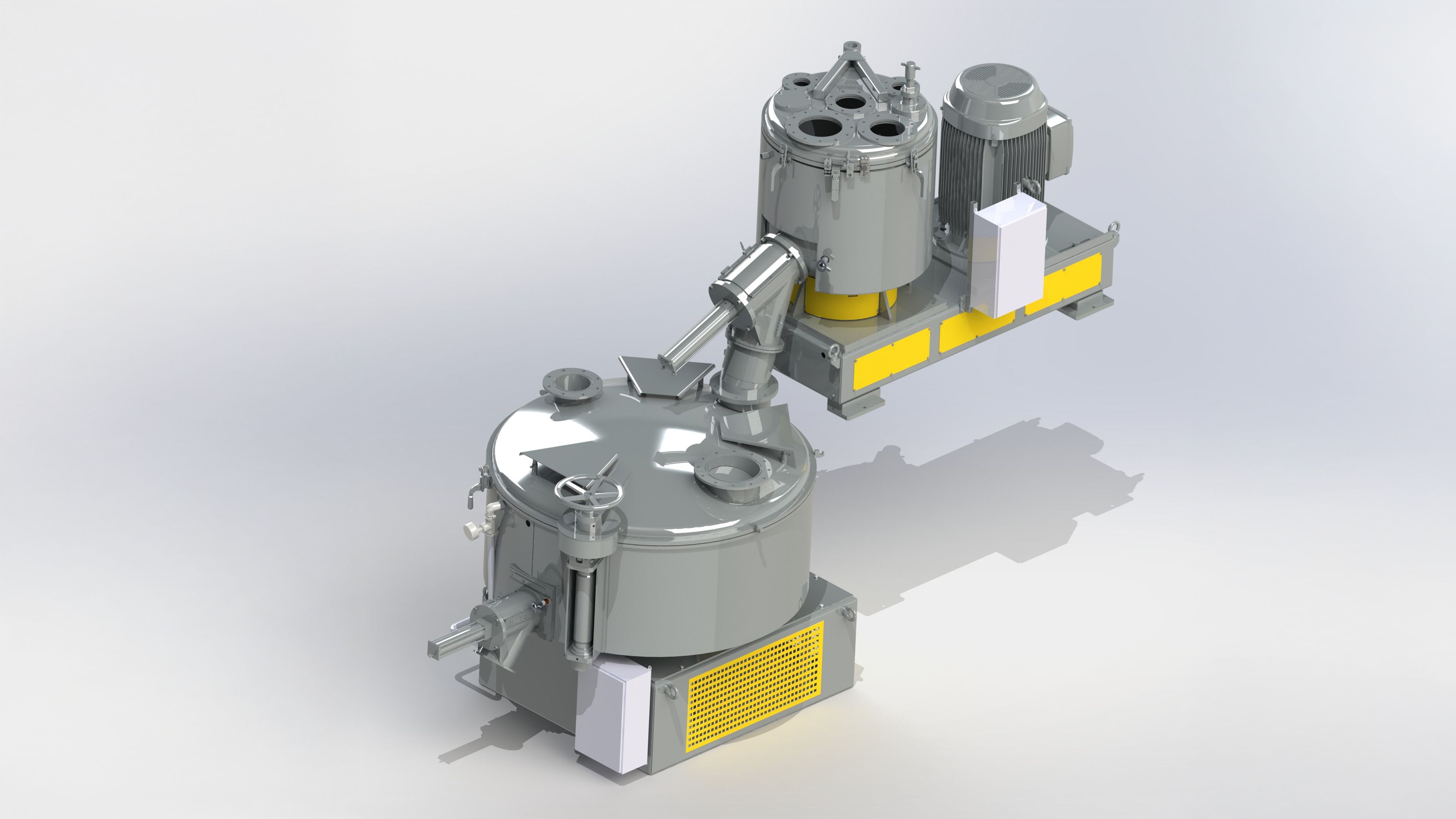

Heating/Cooling Mixer Combination FM-KM

The heating/cooling mixer combination with a vertical cooling mixer for a wide range of applications. It consists of a high-intensity mixer type FM, the best choice for fast and intensive homogenization for dispersing, stabilizing, coating, colouring, crushing, drying, agglomerating, heating, etc., and a vertical cooling mixer type KM for fast and effective cooling and the best possible cleaning.

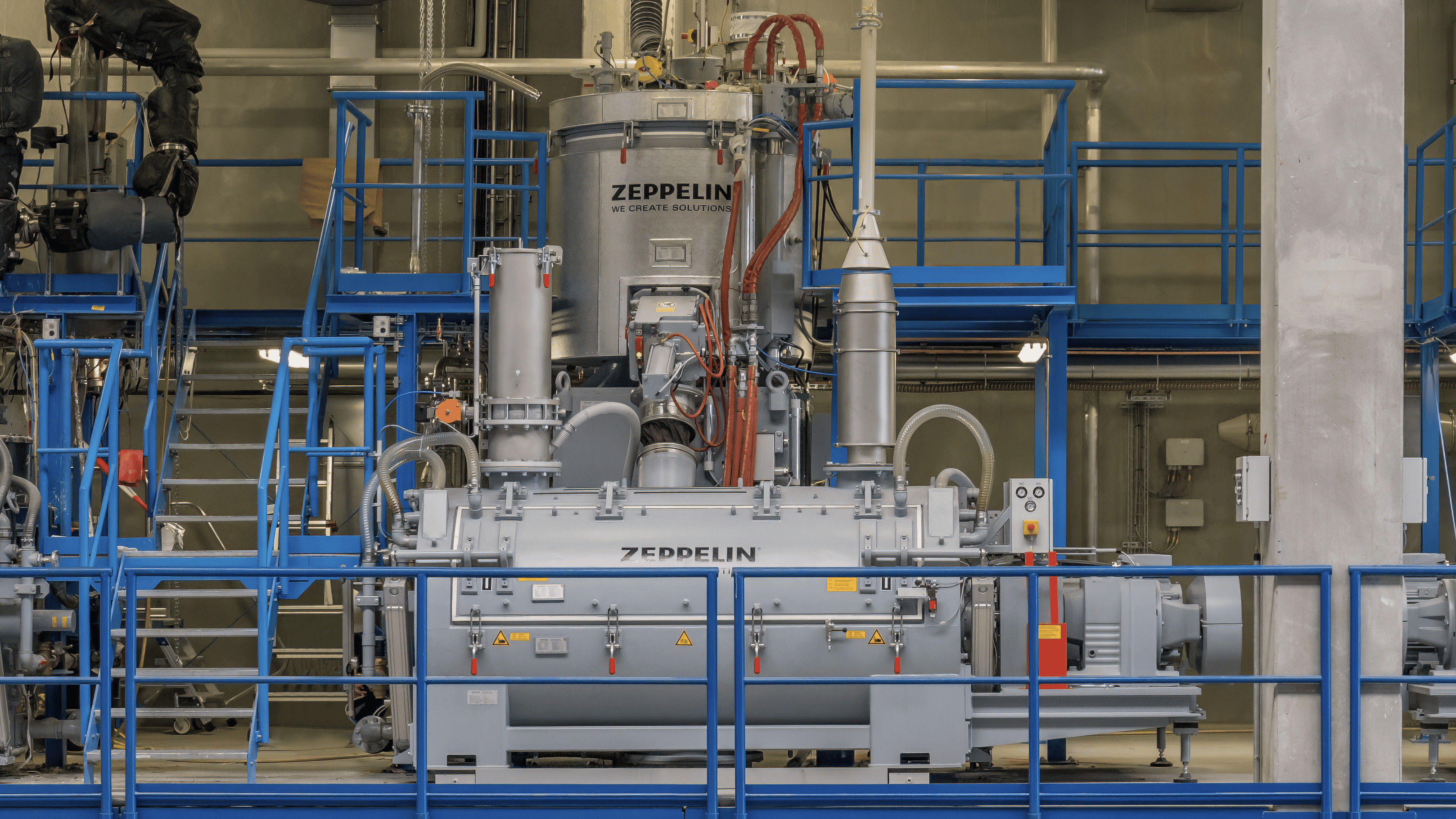

Heating/Cooling Mixer Combination FM-HC

The heating/cooling mixer combination with horizontal cooling mixer for a wide range of applications and high throughput. The system consists of a high-intensity mixer type FM and a horizontal cooling mixer type HC. The high-intensity mixer FM is the best choice for fast and intensive homogenization for dispersing, stabilizing, coating, colouring, crushing, drying, agglomerating, heating and more. The HC horizontal cooling mixer ensures maximum cooling capacity.

Need more details? Our contact persons will be happy to assist you

Dr. Klaus Steingröver

Head of Sales Mixing Technology

Our Customer Services for You at a Glance

Show all Customer ServicesZeppelin Technology Center Kassel

Test, develop, optimize in our laboratory for process technology

At our technology center in Kassel, the essential processes of mechanical process engineering - in particular mixing technology - are available for the plastics processing and chemical industries. Because in order to achieve improvements for our customers' products, it is not always enough to adapt technical machine details to production parameters. We develop completely new processes for processing and producing sensitive raw materials for and together with our customers. Results can be checked immediately in our state-of-the-art laboratory.

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH