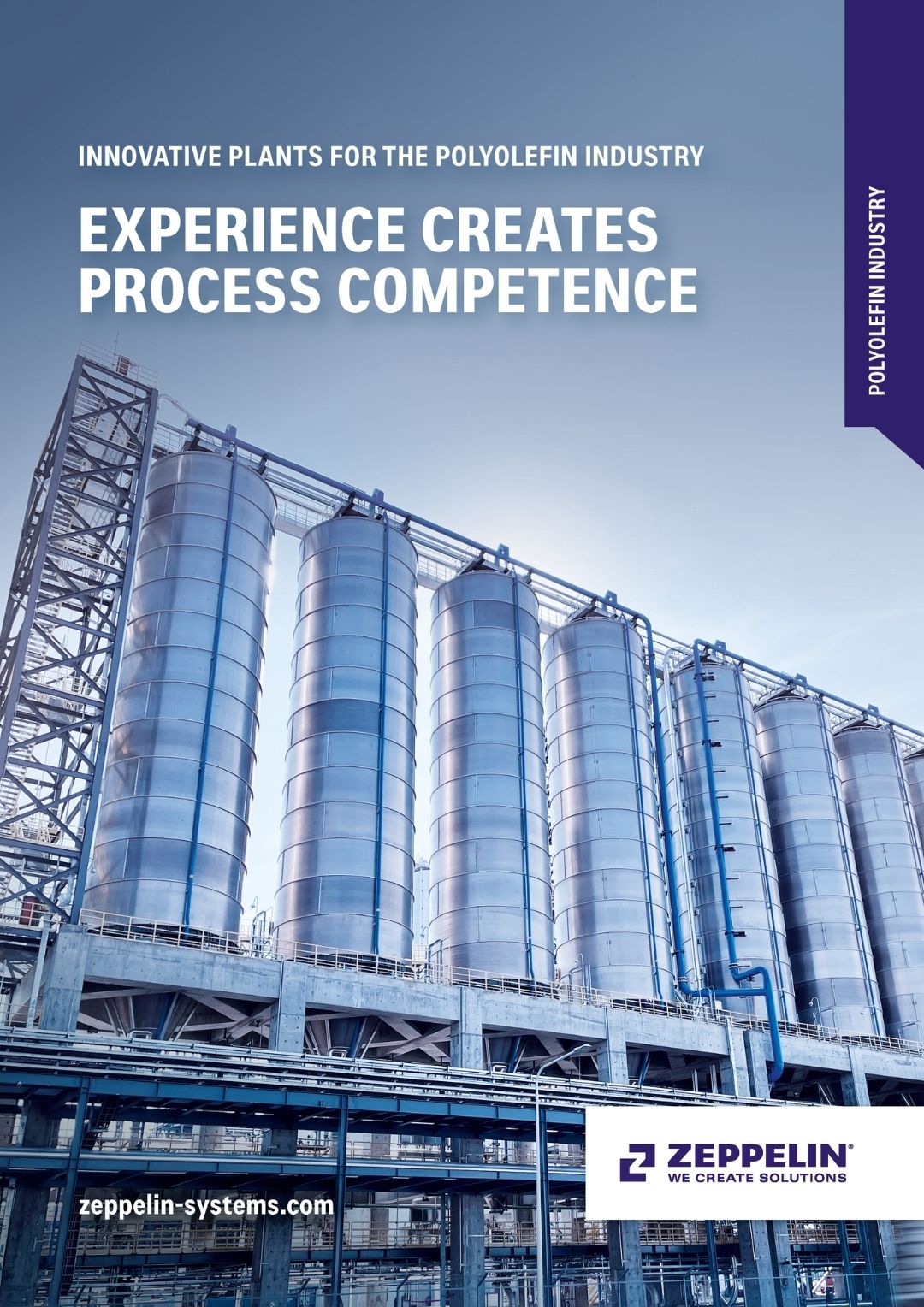

Polyolefins

Innovative plants for the polyolefin industry

Proven technology and experience build process competence

Zeppelin Systems specializes in the design, construction, and technological advancement of polyolefin plants. Each installation is precisely tailored to your products and requirements. To achieve this, we integrate all components for conveying, blending, dosing, storage, and dedusting into a single, cohesive system that prioritizes your high-quality bulk materials. Together, we’ll extract maximum performance from your processes — regardless of location and even under the most extreme conditions. Our commitment doesn’t end with plant delivery: we remain at your service after commissioning for trial runs, training, or ongoing support. With our 360° service, you’ll receive professional assistance at every phase of your project.

Benefits

Our advantages for the industry

Expertise in plant engineering

In addition to complete plants, Zeppelin Systems offers a wide range of diverse process steps (homogenizing, screening, degassing, cooling, etc.), pneumatic and hydraulic conveying systems as well as numerous storage-silo options (Bolt-Tec, Panel-Tec).

Global expertise and local presence

Worldwide solutions with local integration (local & global footprint) - supported by offices in over twelve countries.

Decades of experience and implementation

Our expertise encompasses feasibility studies, cost estimates, Front End Engineering Design (FEED), Process Design Packages (PDP), and Basic Design packages. We also offer a wide range of global references for polyolefin plants. Thanks to our extensive expertise in process engineering, sales, key components, and project management through to service, we can implement your plants quickly, safely, and cost-efficiently—and support you throughout the after-sales phase.

Areas of application

Areas of application

Zeppelin Systems covers the entire process chain in the plastics industry - from polymerization through bulk-material storage and packaging. We are particularly valued for the seamless integration of our systems and components into the overall process. We meet the required quality standards (ISO, ...) and are committed to corporate social responsibility (CSR). For example, we work with certified suppliers and take responsibility for environmental protection.

Solution Provider

Thanks to our expertise in handling bulk materials, we deliver a customized concept precisely tailored to your site and product requirements.

Swift project implementation

All polyolefin plants benefit from our extensive project-management experience - whether producing packaging materials, molded components for vehicles and computers, construction materials, sports textiles, or medical and hygiene products.

We are problem solvers

We are thus specialists for e.g. POE, UHMWPE or EVA systems. EVA granulate, which - thanks to its flexibility, softness, and UV resistance - provides optimal cushioning in applications such as flooring installations, solar panels, and sports footwear, and also serves as a base for hot-melt adhesives.

Technological innovation

We provide products / equipment of the highest quality and purity, which are required, for example, for the production of XLPE granules, which in turn are needed for special cables in the electrical industry.

Challenges in the manufacturing of polyolefins

CAPEX in focus

The more accurately costs, volumes, timelines, and effort can be defined, the more efficiently a project can proceed in advance. We account for every contingency well before an investment decision, ensuring your investment delivers value from the outset.

Low OPEX

Our sophisticated solutions for polyolefin plants deliver larger batch capacities with the highest quality and low energy consumption. For example, hydraulic conveying significantly reduces operating costs, saving between 60 % and 80 % of energy compared to pneumatic systems.

High Product Quality Is Achievable

In the manufacture of plastics and in downstream logistics, the product is subjected to mechanical stress. We focus on the quality of the end product and the purity of the bulk material, selecting the optimal process for your product. Our proven screening systems effectively remove dust particles, fibers, and “angel hair.” For cleaning plastic granules—such as removing fiber nests and strands—we use drum screens. Cyclone separators are employed to separate bulk solids from a gas stream, for example in pneumatic conveying systems.

Deep Process Expertise with Attention to Detail

We are highly valued for the seamless integration of our systems and components into the overall process. We develop your entire material supply chain—from raw material to finished product—regardless of whether it is bagged or shipped in bulk.

Process-Oriented Conveying Technology for Superior Product Quality

Conveying distances of up to 1,000 meters are not uncommon in the polyolefin industry today. Our patented Cyclo Feeder, paired with hydraulic conveying, guarantees extremely gentle product feed—even over long distances—with minimal abrasion or loss.

Tailored Degassing and Blending Technology

Process or raw-material variations need not lead to fluctuating product quality in polyolefin production. We offer process silos for degassing, heating, and cooling, as well as blenders. Our blending silos compensate for irregularities in good time: from Multi-Pipe and Multi-Channel units for large volumes, to the Multi-Flow version for small batches and technical plastics, and even fluid-bed blenders for bulk solids with particle sizes below 500 µm. Each installation is customized to your product requirements.

Process steps

Perfectly planned polyolefin processes - from the idea to the customized system

We support you from the very beginning! Even in the earliest planning stages (FEED, feasibility studies), it’s crucial to consider all market conditions, expansion options, and other contingencies. Leveraging our global experience, we successfully launch even the most complex plant projects. We design your plant based on factors such as throughput, product quality, degassing processes, blending, storage, CAPEX, OPEX, and more. With our own high-performance key components - airlocks, diverter valves, sifters, silos, blenders, etc. - you receive a solution or turnkey plant precisely tailored to your needs. In our network of technical centers (one of the largest worldwide), we can conduct full-scale (1:1) testing of your products in advance.

Process and Polymerization

Today, plastics are predominantly sourced from fossil fuels, natural gas, or crude oil. During the cracking process, hydrocarbon molecules are broken down into usable molecules/monomers (carbon chains). Only in the subsequent polymerization are these monomers converted into a solid product—typically in powder form.

Powder conveying from the process to the extruder

The various polyolefin processes each have their own specific requirements that must be taken into account. The finished powder is typically conveyed via a nitrogen loop to powder storage silos (serving as intermediate buffers) or directly to the silo above the extrusion unit, from which the extruder is then fed.

Granulate conveying from the extruder

After polymerization, additives are incorporated. In the subsequent extruder, the finished granulate is produced under high pressure. Following downstream granulate drying, it is typically fed continuously and gravimetrically into a pellet surge hopper. From this vessel, the granulate is conveyed — pneumatically (or alternatively hydraulically) — to the blenders or to the degassing silos, where the next process step occurs.

Homogenization and degassing

To compensate for raw-material fluctuations and varying granulate properties — and to ensure consistent product quality — granulates are blended or homogenized. This is typically done in homogenizing silos, where recirculation and the specific geometry of the blender balance out these variations.

In some processes, it is also necessary to remove residual monomers (degassing), which takes place in degassing silos. Here, a controlled flow of air is evenly distributed through the silo cone across the entire cross-section. This air strips out the residual monomers from the granulate, and they are then fed into the regenerative thermal oxidizer (RTO).

Dust removal and cleaning

During pneumatic conveying over long distances, the granulate experiences abrasion in the form of dust, fibrils, or ‘angel hair.’ For quality reasons, this is unacceptable in the final product. Therefore, this type of abrasion is removed—for example, in product-cleaning systems or sifters. Ideally, this cleaning occurs at the end of the material-flow chain, i.e. before loading into containers or silo trucks, or prior to bagging.

Storage

After homogenization, the granulate is transferred into storage silos for interim holding, before being conveyed for bagging or loaded into containers or silo trucks.

Bagging

From the storage silos, the granulate is conveyed to the bagging silos—ideally via a sifter—to ensure maximum product quality. From the bagging silos, the granulate is then packed into 25 kg bags using FFS machines, or alternatively into big-bags or octabins.

Need more details? Our contact person will be happy to assist you

Services

Discover our comprehensive range of services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs — and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutions

Service

Service without compromise

In the 21st century, optimization often means automation. We ensure that your automation project is a complete success in terms of both efficiency and cost-effectiveness. To achieve this, we rely on cutting-edge control systems whose open architectures prepare you for the challenges of tomorrow—and beyond.

Go to servicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH