Bakery Products

For Results Crafted to Perfection

This Recipe is Destined to Become a Classic

Optimize your products through efficient processes in bakery production - supported by our expertise in raw material management, dough processing and automation.

The facts speak for themselves: bread and baked goods have long been a cornerstone of human nutrition. But never before have the demands on companies in the baking industry been as complex as they are today. Growing consumer demand must be met, strict quality standards upheld, and new trends—such as the rising popularity of high-fiber and gluten-free baked goods—addressed.

That’s why it pays to have a partner you can rely on—one that brings together decades of experience with an innovation-driven mindset. Zeppelin Systems delivers outstanding solutions for every key process step, enabling highly reproducible, market-leading results.

Results crafted to perfection.

Application Areas

Fresh Bakery Products

Shelf-Stable Bakery Products

BENEFIT FROM ZEPPELIN SYSTEMS

Dough Production at the Highest Level

Premium raw material quality

The optimal storage of raw materials is crucial to ensure quality, safety and shelf life in the food industry. We rely on state-of-the-art storage technologies to ensure the highest standards.

precise quantities

Precision is essential for us. Exact weighing and dosing technology ensures the perfect balance of moisture, elasticity and structure in the dough.

exact temperature control

Water and flour temperature in particular are crucial, as they have a significant influence on dough development. Thanks to our many years of experience, we know exactly what is important in this process.

Process Steps with Potential

Efficient Solutions Powered by Zeppelin Technologies and Expertise

A detailed process with tremendous potential—ready to be unlocked. Zeppelin Systems supports you not only with innovative technology components, but also with comprehensive process expertise gained from countless successfully implemented plants worldwide.

Raw material intake

Perfect raw material intake

Right from raw material delivery, we ensure maximum safety by integrating solutions such as feed hoppers, jet vent filters, and fans. This guarantees a dust-free, gentle, and contamination-free transfer of raw materials into the process—regardless of packaging type or product.

Go to separating

Storage

Thought-out storage concepts

We develop customized solutions that take into account cooling, insulation, explosion protection, hygienic design, and optimized cleaning options—ensuring cost-effective and gentle storage of all raw materials.

Go to storage silosDischarge

Intelligent discharge modules

We offer customized discharge solutions such as big bag stations, sack tipping units, or fluidized beds with air loosening to ensure a consistent material flow and precise dosing. Our process experts work closely with you to identify the optimal solution tailored to your specific requirements.

Go to discharge aids

Conveying

Product-specific conveying

Benefit from our customized conveying systems designed specifically for sensitive raw materials. With technologies such as Lean-Tec, Dense-Tec, and Twin-Tec, products are transported gently and efficiently, while energy costs are optimized. The Dense-Tec process, in particular, offers excellent protection for fragile and break-sensitive materials.

Go to conveying

Sieving

Safety sieves for secure product quality

With our screening solutions such as rotary sieve machines and magnetic separators, we ensure the reliable removal of foreign particles from incoming materials. Whether used as pre-sieves, post-sieves, or inline screening units, our systems provide ideal starting conditions for smooth processes and consistently high product quality.

Go to screening machines

Weighing & Dosing

Maximum precision in weighing and dosing

Our customized solutions for dosing and weighing range from manual systems to fully automated high-performance installations such as MicDos, MinDos, and MacDos. With advanced technologies like dosing and conveying screws or KOKEISL technology, even sensitive products are handled gently and precisely.

Go to weighing & dosing

Homogenizing

Even distribution thanks to coordinated mixing concepts

We offer versatile solutions for a wide range of raw materials such as pre-doughs, glazes, and bulk materials. The ShearDos mixer ensures uniform suspensions through intensive shearing, while the Codos mixer provides continuous mixing and a temperature-controlled trough design, creating optimal processing conditions for your products.

Go to mixing silosEight benefits for the industry

Experience and expertise

Decades of experience in plant engineering for the food industry result in economical, resource-efficient, and highly effective solutions for our customers—whether for a new installation or the modernization of an existing brownfield facility.

Industrial-scale testing

The Food Technology Center is equipped with test facilities for dosing, conveying, weighing, sieving, and mixing of formulations. On-site trials and tests enable system optimization and provide a reliable basis for designing efficient plant solutions.

Tailored solutions

All systems are precisely tailored to the specific requirements of your processes and materials.

Innovative technologies

Cutting-edge technologies for maximum energy and process efficiency, reliability, and sustainability in the processing of high-quality bulk materials.

Global delivery and support

A global presence ensures a comprehensive worldwide service and maintenance network.

High efficiency and cost savings

Optimized processes and automated workflows reduce operating costs and boost productivity.

Top quality standards

Use of premium materials and technologies that ensure long-term reliability and low maintenance costs.

Sustainability focus

Systems designed to reduce energy consumption and emissions actively support your environmental and sustainability goals.

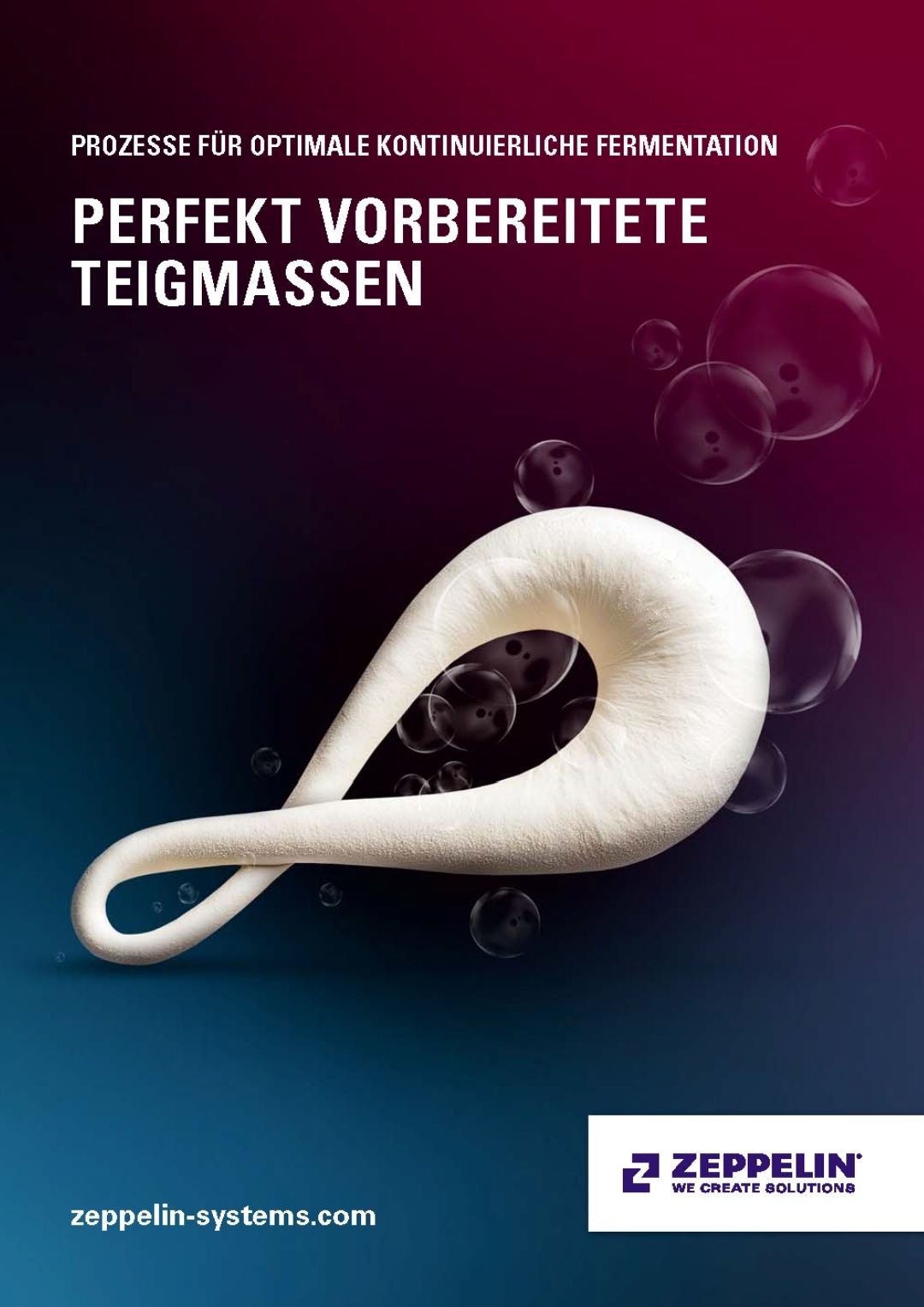

With Zeppelin, you gain maximum control over fermentation, pre-mixing, and kneading processes

Moistening and mixing with the DymoMix

The DymoMix operates at extremely high speed and ensures dust-free processing while producing doughs with a consistently homogeneous texture. Dry ingredients such as flour are fully wetted with liquids within seconds, aerated, and thoroughly mixed. This process results in high-quality doughs that can be used directly or seamlessly transferred to downstream production steps such as batch kneading or the continuously operating Conti-Kneter.

Mixing and kneading system with Codos

Whether it’s your favorite cookie, a pretzel, or a chia roll – consumers expect their product to always taste the same. The best foundation for this is the continuous mixing and kneading system Codos. It delivers consistent dough quality around the clock, even in high volumes: 20,000 pretzels per hour, 2 million rolls per day, or 3 tons of cookie dough per hour are no problem. The result is always uniform and optimal, with a stable dough temperature maintained throughout the process.

Unlike traditional batch kneaders, the Codos system can save up to 30% energy. It includes the entire dry and liquid ingredient dosing, as well as the mixer and kneader. Thanks to its modular design—featuring the Codos Tower, DymoMix™, and Codos NT kneader—the solution from Zeppelin Systems can be flexibly integrated to meet your specific production needs.

Need more details? Our contact person will be happy to assist you

Ingo Pütz

Global Market Manager Sales Food Processing Plants

Services

Discover our comprehensive range of services

Zeppelin Technical Center

Industrial-scale testing

Testing is good; testing at a 1:1 scale under real-world conditions is even better. To support this, we have established optimal facilities at our Friedrichshafen technical center: based on your recipe and desired throughput, we identify the plant technology tailored to your needs — and test the complete system for you in live operation.

Go to technical center

Automation

Automation with foresight

Above all, your plant must do one thing: run and deliver. That’s why we provide you with reliable, professional service. Rely on our global service network for expert consultation and extremely fast spare-parts supply to minimize downtime. When needed, we’re also at your side digitally—from virtual troubleshooting to online-supported commissioning.

Go to automation solutions

Service

Service without compromise

In the 21st century, optimization often means automation. We ensure that your automation project is a complete success in terms of both efficiency and cost-effectiveness. To achieve this, we rely on cutting-edge control systems whose open architectures prepare you for the challenges of tomorrow—and beyond.

Go to servicesResources

Brochures for download

Explore more from the Zeppelin Systems portfolio

Products

© 2026 Zeppelin Systems GmbH